principle of of a ball mills r

2020-05-26T12:05:57+00:00

The working principle of ball mill Meetyou Carbide

22/05/2019 The ball mill consists of a metal cylinder and a ball The working principle is that when the cylinder is rotated, the grinding body (ball) and the object to be polished (material) installed in the cylinder are rotated by the cylinder under the action of friction and centrifugal force18/05/2012 Ball Mill Working Principle Grinding is usually performed wet, although in certain applications dry grinding is used When the mill is rotated, the mixture of medium, ore, and water, known as the mill charge, is intimately mixed; the medium comminuting the particles depends on the speed of rotation of the mill and the shell liner structureball mill working principle Henan Deya Machinery Co, LtdPrinciple Of Work Of A Ball Mills Ball MillsMineral Processing Metallurgy Working Principle Operation The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill for example a 5′ x 5′ Ball Mill has a working diameter of 5′ inside the liners and has 20 per cent capacity Principle Of Working Of Ball Mill leclosdelabussierefr

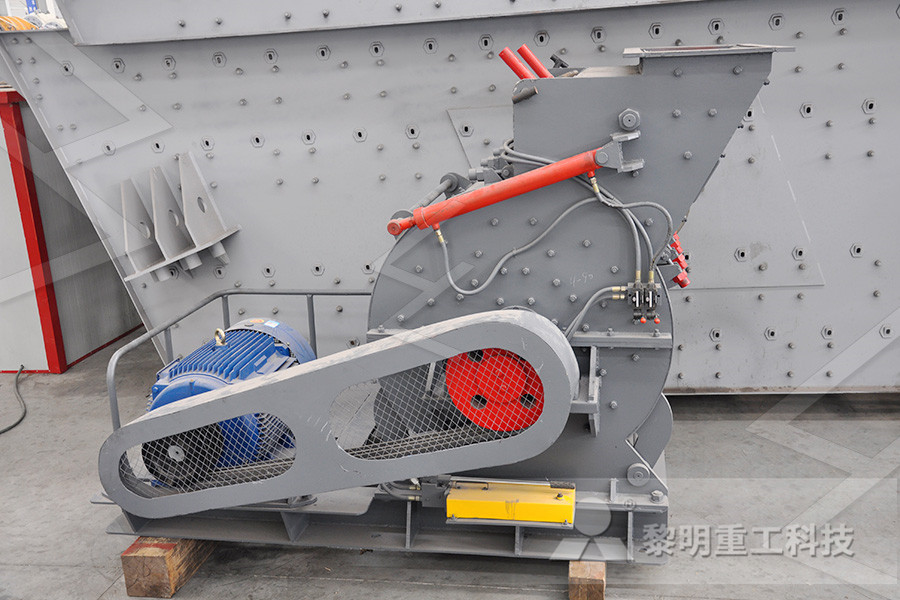

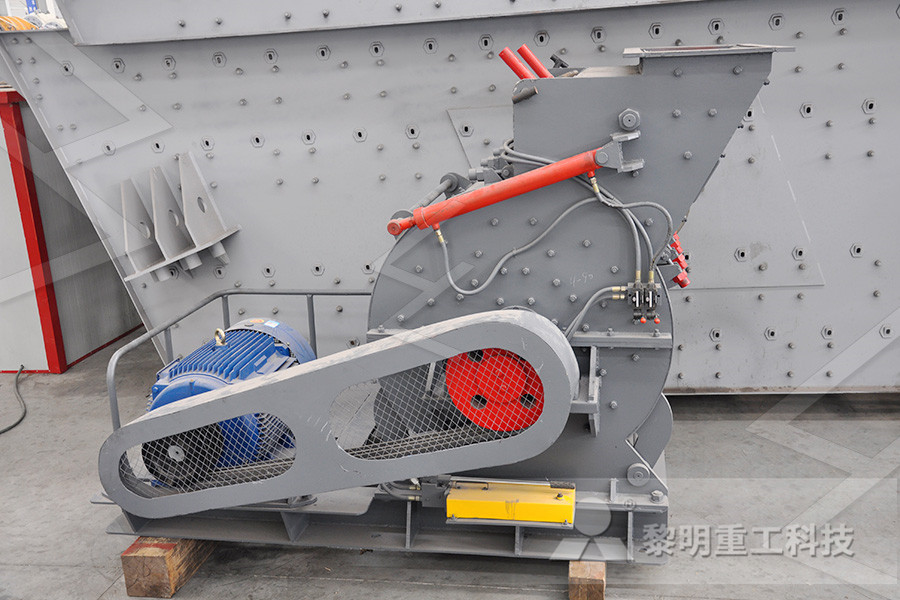

Ball Mill Working Principle And Main Parts

34 lignes The ball mill host comprises a cylinder body, cylinder body made of inlaid useful Basic Principle Of Ball Mill In Kenya Basic Principle Of Ball Mill Point Basic principle of ball mill point a ball end mill is constructed of a round cutting edge and used in the machining of dies and molds roughing end mills also known as hog mills are used to quickly remove large amounts of material during heavier operations the tooth design allows for little to no vibration but leaves principle of the ball mill monplaisirgourmandfr11/05/2021 Construction of Ball Mill The ball mill consists of a hollow metal cylinder mounted on a shaft and rotating about its horizontal axis The cylinder can be made of metal, porcelain, or rubber Inside the cylinder balls or pebbles are placed The balls occupy between 30 and 50% of the volume of the cylinder The diameter of the balls depends on Construction and Working of Ball Mill Solution Pharmacy

Ball Mill Working Principle And Main Parts

Ball Mill Working Principle To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken to the height of a Ball MillsMineral Processing Metallurgy Working Principle Operation The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill for example a 5′ x 5′ Ball Mill has a working diameter of 5′ inside the liners and has 20 per cent more capacity than all other ball mills principle of work of a ball mills remontyskowronplNov 18, 2008 Basic principle Ball mill is generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns To achieve a reasonable efficiency with ball mills, they must be operated in a closed system There is a specific operating speed for most efficient grinding At a certain point, controlled by the mill basic principles of ball mill daikichisushifr

principle of the ball mill monplaisirgourmandfr

Basic Principle Of Ball Mill In Kenya Basic Principle Of Ball Mill Point Basic principle of ball mill point a ball end mill is constructed of a round cutting edge and used in the machining of dies and molds roughing end mills also known as hog mills are used to quickly remove large amounts of material during heavier operations the tooth design allows for little to no vibration but leaves Ball mills give a controlled final grind and produce flotation feed of a uniform size Ball mills tumble iron or steel balls with the ore The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds The feed to ball mills (dry basis) is Ball Mill an overview ScienceDirect Topics11/05/2021 Construction of Ball Mill The ball mill consists of a hollow metal cylinder mounted on a shaft and rotating about its horizontal axis The cylinder can be made of metal, porcelain, or rubber Inside the cylinder balls or pebbles are placed The balls occupy between 30 and 50% of the volume of the cylinder The diameter of the balls depends on Construction and Working of Ball Mill Solution Pharmacy

principle and working of ball mill takeaseatfr

Ball Mill Woking Principle Aug 12, 2020 Ball Mill Woking Principle Ball mills mineral processing metallurgy working principle operation the apparent difference in capacities between grinding mills listed as being the same size is due to the fact that there is no uniform method of designating the size of a mill for example a 5 x 5 ball mill has a working diameter of 5 inside HIGH ENERGY BALL MILLS sunwaytw Principle of overflow ball mill: the main component is a cylinder with diameter and length at a reasonable proportionDriven by the transmission device, the cylinder rotates with the materials fed from the cylinder inlet and crushed by the falling impacts and autogenous grinding of the steel balls and ores in Ball Mill principle of a ball mill plageles3pinsfrBasic principle of ball mill point a ball end mill is constructed of a round cutting edge and used in the machining of dies and molds roughing end mills also known as hog mills are used to quickly remove large amounts of material during heavier operations the tooth design allows Read More Ball Mills an overview ScienceDirect Topics Oleg D Neikov, in Handbook of Non principles of operations of ball mill

Principle Of Work Of A Ball Mills osteopathe91essonnefr

Principle Of Work Of A Ball Mills cafebliss Ball MillsMineral Processing Metallurgy Working Principle Operation The apparent difference in capacities between grinding mills listed as being the same size is due to the fact that there is no uniform method of designating the size of a mill for example a 5′ x 5′ Ball Mill has a working diameter of 5′ inside the liners and has 20 per22/12/2014 The Working Principle Of A Ball Mill By Steven Harrisson, December 22, 2014 As one of the most efficient grinding machines, the ball mill is a powerful device for grinding all types of materials into fine powder Over The Working Principle Of A Ball Mill 20/06/2019 Learn how a ball mill works, all of its main parts and some of its design features! This 3D animated video allows you to see all the internal parts of a ballHow Ball Mills Work (Engineering and Mining) YouTube

principle and operation of ball mill

Ball Mill Working Principle To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken to the height of a 10/03/2020 Ball mills work by using balls to grind materials Materials such as iron ore, pain and ceramics are added to the ball mill Next, the ball mill is activated so that it rotates — either on its vertical or horizontal axis As the ball bill rotates, the balls bounce around while striking the enclosed material The force of these strikes helps to grind the material into a finer, less What Is a Ball Mill? Monroe EngineeringMonroe EngineeringBall Mills Mineral Processing Metallurgy 2017/02/12 In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals the ore in principle of ball mill

principle of a ball mill plageles3pinsfr

HIGH ENERGY BALL MILLS sunwaytw Principle of overflow ball mill: the main component is a cylinder with diameter and length at a reasonable proportionDriven by the transmission device, the cylinder rotates with the materials fed from the cylinder inlet and crushed by the falling impacts and autogenous grinding of the steel balls and ores in Ball Mill Ball Mill Woking Principle Aug 12, 2020 Ball Mill Woking Principle Ball mills mineral processing metallurgy working principle operation the apparent difference in capacities between grinding mills listed as being the same size is due to the fact that there is no uniform method of designating the size of a mill for example a 5 x 5 ball mill has a working diameter of 5 inside principle and working of ball mill takeaseatfrBasic principle of ball mill point a ball end mill is constructed of a round cutting edge and used in the machining of dies and molds roughing end mills also known as hog mills are used to quickly remove large amounts of material during heavier operations the tooth design allows Read More Ball Mills an overview ScienceDirect Topics Oleg D Neikov, in Handbook of Non principles of operations of ball mill

Ball Mill Critical Speed Mineral Processing Metallurgy

19/06/2015 Ball and SAG Mills are driven in practice at a speed corresponding to 6081% of the critical speed, the choice of speed being influenced by economical considerations Within that range the power is nearly proportional to the speed Mill rotating speed impacts grinding rates A great little paper about this is ” Effect of Fraction of Mill Critical Speed on Kinetic Breakage “ principle and operation of ball mill Flotation, Principle of operation Ball mills are giant drums that are filled to between 30 and 40% of their volume with Get Price principles of ball mill operation principles of ball mill operation ; CS Cone, ball mill operation and principle Ball Mill Operation Principle Of Raw Mill Coal Find the Right and the Top Ball Get Price Priciple Of principles of operations of ball mill