Crusher rock with impact crusher r

2020-07-03T16:07:33+00:00

Impact Crusher Eastman Rock Crusher

Impact crusher are named after the method that reducing rock material size, just as its name implies, impact crusher crushes materials by the impact energy An impact crusher speeds up the feed material to high speed, then throws fastmoving rocks against the crushing chamber walls and each other09/12/2021 One such way to process these materials is sending gravel, rock, and sand through an Impact Crusher, which breaks up the material by either striking it with a rapidly moving blow bar or by throwing it into a stationary anvil where it breaks upon impactWhat is an Impact Crusher?What is an Impact Crusher Impact rock crushers use striking reduce the stone material size, not pressure The equipment is suitable for mining, metallurgy, cement, building materials, chemical industry, water, and electricity, etc Two types of impactors are the vertical shaft and horizontal impact crushersImpact Crusher Rock Crusher Machine Manufacturer JXSC Mine

Rock Crusher Eastman Rock Crusher

Impact crushers tend to be used where shape is a critical requirement and the feed material is not very abrasive The crushing action of an impact crusher breaks a rock along natural cleavage planes, giving rise to better product quality in terms of shape Crushing stagesdove impact crushers, also referred to as counter impact crushers are highly ideal rock reduction machines designed for primary, secondary and tertiary crushing of raw material for production of the construction material, ore crushing, mining, chemical industry, steel and iron industry, hard coal and lignite, lime stone, gypsum and various other Impact Crushers Precise Shape Of Cubical End Crushed PFW impact crusher PFW impact crusher is a new type of highperformance hydraulic crusher developed with internationally advanced impact crusher technology It is very suitable for coarse, medium and fine crushing of various soft and mediumhard minerals and rocks Advantage Integral cast steel structure bearing seat Heavyduty rotor designWhat Is Impact CrusherWorking Principle, Parts And Types

Rock Crusher Jaw Cone Rock Crushing Machine

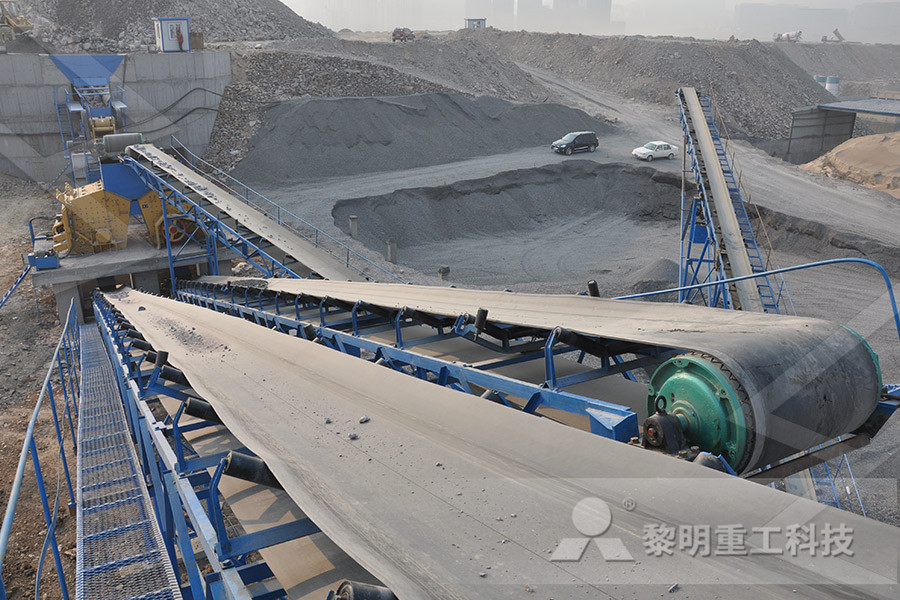

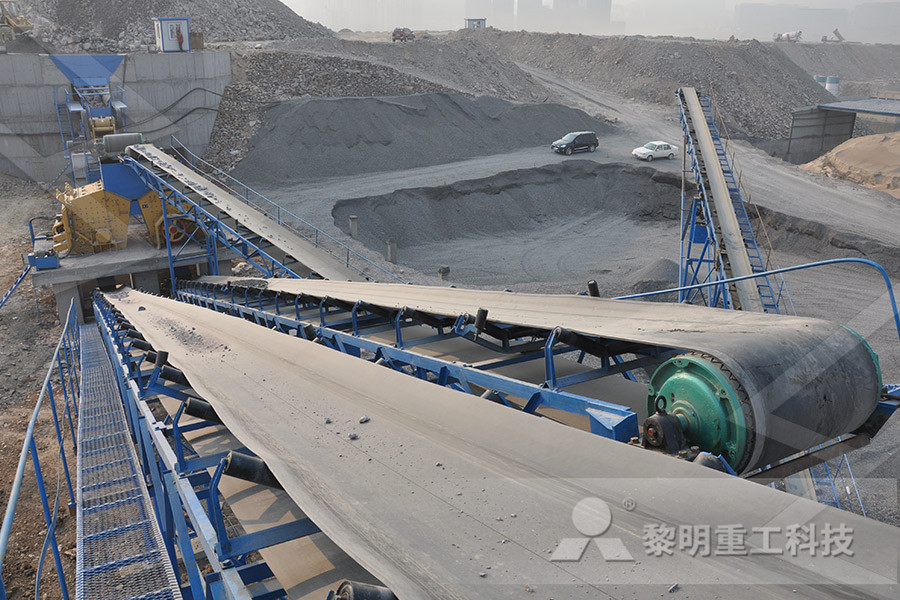

Introduction of Impact Crusher: Impact crusher has wide applications This kind of rock crushing equipment for sale has become the crucial equipment to crush stone materials in highway, highspeed railway, water conservancy project and other fieldsImpact Crusher is the kind of secondary rock crusher A rock crusher is a machine designed to take large rocks as and reduce them to smaller rocks, gravel, or rock dust Rock crushers produce aggregates and readytoprocess mining ores, as well as rock fill material for landscaping and erosion control A secondary crusher is a machine that is used after primary Impact Crusher – Residential And Commercial ConstructionSome operations also use impactstyle crushers after they have already used a different type of rock crusher that produces a more elongated stone This helps further shape the crushed material into a finer consistency with a more cubical nature Impact crushers tend to be less expensive than compression crushers (aka cone and jaw crushers, which we already covered) Types of Rock Crushers Quarry Crushing Equipment Kemper

Impact crushers highquality impactors Outotec

As the name suggests, an impact crusher accelerates the feed material to high speed and then flings the fastmoving rocks against the walls of the crushing chamber and each other This collision, impact, causes the stones to break down to smaller sizes The range of impact crushers consists of stationary impacts crushers presented on this page, mobile impact 【Impact Crusher Working Principle】Impact crusher is a machine that breaks materials using the impact of energy The rotor rotates of our impact crusher with a high speed driven by a motor When the materials get into the hammer effect area, they are impacting to break with the hammer on the rotor and then threw to the impacting position to take another crushing After Impact Crusher JXSC MachineImpact Rock Crusher: Aimix’s impact crusher is one important type of rock crusher machine for sale It adopts the latest technology, absorbs the advantages of many domestic and foreign impact crushers, and has very superior performance Its excellent features are as follows: Firstly, the clearance between the plate and the hammer can be adjusted conveniently, and the Rock Crusher Jaw Cone Rock Crushing Machine

Impact Rock Crusher Manufactured in China for Sale

Impact rock crusher is also known for its shiptype hammer, reliable locking structure, good impact strength and wear resistance and stable discharge size Besides, the new highabrasion materials just as brittle rocks, limestones, cobblestones, gold mine, copper, etc, are used in large quantities to reduce the wear of wear parts, extend the replacement cycle, and save costs So Impact Crusher is mainly usde in coarse, midium, and fine crush, such as, limestone, coal, Calcium Carbide, quartz, dolomite, sulfuration iron ore, gypsum, chemical raw material etc, under midium hard brittle material the ideal size of PF Series Impact Crusher is from 100500mm, the max feed size shouldn't exceed the specified value Users can adjust the space between the Impact CrusherSANME22/03/2022 Impact Crusher This type of stone crusher is a rockcrushing tool that involves more impact than high pressure This tool has a rotary clock system with a fairly high rpm speed Impact crushers are usually used to crush rocks with raw material sizes that are not too large The result of this type of stone crusher is a small and homogeneous size Common stone crushing line equipment in Indonesia AMC Crusher

Impact Crusher crusherinc

The JOYAL Impact Crusher is used for primary, secondary and fine crushing of all kinds of stones and rocks with compressive strength less than 350 MPa such as granite, marble, and limestone The Impact Crusher is widely used for sand and rock production in the industry of roads, railways, reservoir, electricity power, building materials and so onRock crusher or impact mill plans? small portable impact mill – ore mineral crushers small crusher,small rock crushers,mini crusher,small jaw little guy" if you need a jaw crusher, roller crusher, portable mill, or any form of small mobile impact Impact Mills Our microgrinding impact mill systems are designed to be fast, efficient, and long lasting The freestanding 16” Small Rock Impact Mill Crusher Mills, Cone Crusher, Jaw Impact crusher is a star product of crusher machine in the crushing plant, usually used for coarsemedium crushing of limestone, coal, calcium carbide, quartz, dolomite, iron sulfide ore, gypsum, and many other medium hardness Impact Rock Crusher Complete Crushing Plant

What is an Impact Crusher?

09/12/2021 When the rock impacts the anvils or rock shelves, it shatters along natural stress lines, creating a uniform, cubical product This method is both economical and simple to operate The VSI has the best rate of production of smaller sizes ( ½”) as it is the only crusher that does not close off the discharge side to make a smaller product But are also limited in feed size Some operations also use impactstyle crushers after they have already used a different type of rock crusher that produces a more elongated stone This helps further shape the crushed material into a finer consistency with a more cubical nature Impact crushers tend to be less expensive than compression crushers (aka cone and jaw crushers, which we already covered) Types of Rock Crushers Quarry Crushing Equipment Kemper10/01/2020 Impact crusher can crush aggregates with excellent granularity because of flexible and variable adjustment methods, making the diameter of final aggregates that can be produced reach 05mm, 510mm, 1015mmIn addition, people are all inclined to purchasing an impact rock crusher because it can reduce various aggregates to beautiful particle size and little Impact Rock Crusher—Ideal Aggregates Making Machine

Impact CrusherSANME

So Impact Crusher is mainly usde in coarse, midium, and fine crush, such as, limestone, coal, Calcium Carbide, quartz, dolomite, sulfuration iron ore, gypsum, chemical raw material etc, under midium hard brittle material the ideal size of PF Series Impact Crusher is from 100500mm, the max feed size shouldn't exceed the specified value Users can adjust the space between the Impactor operation is based on the principle of rapid transfer of impact energy to the rock material Impactors produce cubic products, and they can offer high reduction ratios as long as the feed material is not too fine This means that in certain cases it is possible to use a single impact crusher to carry out a task normally done in several crushing stages using Crushers All crusher types for your reduction needs 23/06/2015 Impact Crusher Buy a small impact crusher: Rock Particle Breakage in Impact Crushing ly increasing operating costs for minerals beneficiating plants continue to be the biggest single problem in maximizing profitability from these operations The average world inflation rate has been increasing over the last decade and shows little sign of easing The Impact Crusher Working Principle

Impact Crusher Machines Williams Patent Crusher

Impact crushers rely on gravitational or dynamic physical impact for size reduction of materials such as rock, concrete, gravel, and more, rather than through a standard compressiononly method of crushing Typically, impact crushers either use gravity to drop material onto a surface, or the material is fed into a chamber containing a highspeed rotor with hammers or blow bars 28/02/2020 1 Application 1 Jaw crushers are mainly used as primary crushers, it can crush hard material, such as granite, basalt 2 Impact crusher is usually used as a mediumfine hardness crusher, such as limestone, concrete, it has good crushing efficiency of some brittle material It mainly crushes the small material discharge from the jaw crusherJaw Crusher VS Impact Crusher (A Comparison from 7 Points ROC IMPACT offers a wide range of rugged crushers designed for mines and quarries: Jaw crusher, Cone crusher, Impact crusher and Mobile crushing and screening unit Jaw Crushers ; Cone Crushers ; Impact Crusher ; Screens ROC IMPACT vibrating screens are built to last and are installed on site with an angle of 1520° Their basic design makes them especially useful CRUSHER ROC IMPACT and Equipment for mines and quarries