equipment of cement plant r

2020-05-19T05:05:05+00:00

Cement Equipment, Cement Plant Equipment Cement Plant

AGICO CEMENT can manufacture cement equipment including cement crusher, raw mill, cement kiln, cement mill and others, which can be widely used in cement crushing plant, cement clinker plant, cement grinding plant and other fields FREE Quotation cement raw materials production27/09/2019 Cement mill is another necessary cement equipment of the cement plant After raw material crushing, cement mill plays vital role in the further cement manufacturing process Cement ball mill, vertical cement mill, and cement roller Cement Euipment Overview Cement Making Cement PlantThe range of components are used for various material handling requirements in cement plant Screw Conveyor; Airslide Conveyors ; Diverters (Bottom, Side, Vertical) Flow Dividers; Flow Control Gates; Slide Gates; Rotary Valves; Shut off Valves; Pressure Relief Valves; Expansion Joints; Loading Spouts; Pneumatic conveying equipment ; Screw Pump for conveying of fluidizedCement Plant Equipment Ecorporates

Cement Plant, Cement Equipment Cement Plant Manufacturer

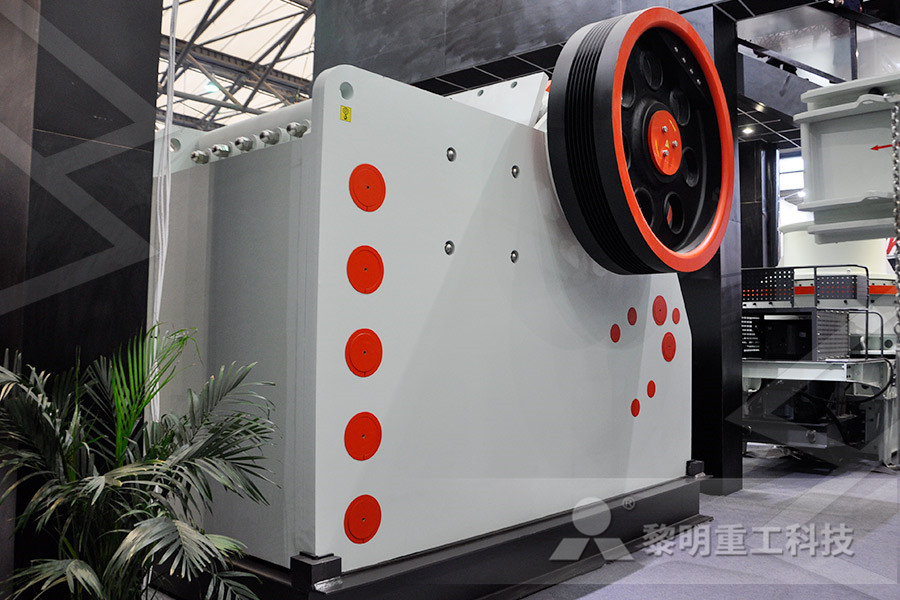

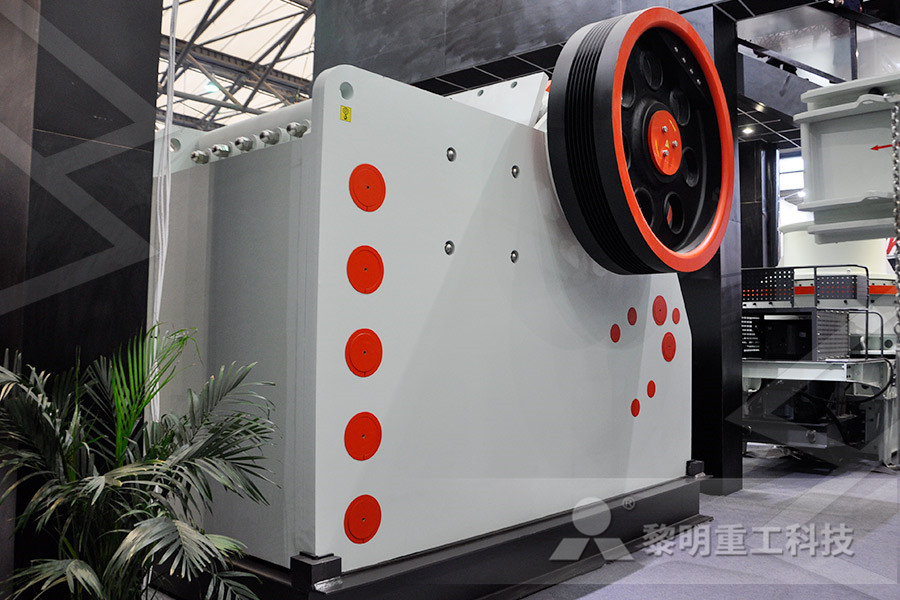

Cement manufacturing plant includes cement equipment such as cement crusher, cement ball mill, rotary kiln, cement dryer, cement roller press, and other cement plant equipment for cement production Cement Manufacturing Plant AGICO CEMENT provides the cement grinding unit generally consists of cement ball mill, cement vertical mill, etcAs we all know, there are two elements to affect the quality and efficiency of the cement production line: cement production process and cement equipment Cement equipment refers to all equipment in the cement plant, such as cement mill, cement crusher, cement kiln, cement silo, cement preheater, etc Today we will focus on the cement Read More »equipment Archives Cement PlantCement Equipment AGICO supplies cement crusher, cement rotary kiln, cement ball mill, vertical cement mill, preheater and other related cement plant equipment Cement crusher: the raw materials is crushed into required sizes by different types f cement crushers Jaw crusher Cone crusher Impact crusher Hammer crusher Mobile crusherCement Plant Cement Manufacturing Plant EPC Project

Cement Plant for Sale Cement Plant Equipment Design

Cement Equipment Our cement equipment has a variety of models, which can meet the needs of different scale cement production Cement Crusher Rotary Kiln Cement Mill Stacker Reclaimer Rotary Dryer Cyclone Preheater Conveyor Grate Cooler Coal Mill Cement Mill Separator Why Choose Us We are your expert cement plant manufacturer OneStop EPC ServiceCement Plant Process Equipment: We manufacture Supply all type of Cement Plant Process Machines Equipments including Cement Plant Belt Conveyors Screw Conveyors Bucket Elevator Jaw Crusher Single Roll Crusher Hammer Mill Vibrating Screen Ball Mill Rotary Dryer Pneumatic Bag Packing Machine Mobile Bag Packing Machine Material Cement Plant Manufacturers, Cement Plant Equipment Frigate has the technical knowhow to design, manufacture, supply installation of a wide range of cement plant equipment List includes the following equipment: Clinker Grinding Plants Ball Mills Mill Heads Mill Bearings Classifiers Silo Feeding Extraction Systems Bulk Material Handling Bag Handling Loading Unloading SystemsCement Plant Equipment Manufacturer and Supplier in

Cement manufacturing components of a cement plant

The material formed in the kiln is described as 'clinker' and is typically composed of rounded nodules between 1mm and 25mm across After cooling, the clinker may be stored temporarily in a clinker store, or it may pass directly to the cement mill The cement mill leading cement plant manufacturer AGICO CEMENT can manufacture cement equipment including cement crusher, raw mill, cement kiln, cement mill and others, which can be widely used in cement crushing plant, cement clinker plant, cement grinding plant and other fields FREE QuotationCement Equipment, Cement Plant Equipment Cement Plant Cement Plant Equipment Ecorporates GmbH has been prominent supplier of key heavy equipment and complete systems for cement manufacturing We are in partnership with renowned workshops and fabrication facilities in Europe and China for manufacturing of cement plant equipment Our partner manufacturing facilities are already the OEM for famous Cement Plant Equipment Ecorporates

Cement Euipment Overview Cement Making Cement Plant

27/09/2019 Cement equipment refers to the cement making machines that are applied to the cement manufacturing plant Before learning the cement equipment, we learn the process of cement manufacturing process first Cement manufacturing process In general, we can divide the cement production line into three main steps: raw material preparation of cement, clinker Cement equipment refers to all equipment in the cement plant, such as cement mill, cement crusher, cement kiln, cement silo, cement preheater, etc Today we will focus on the cement Quiz: How Much Do You Know About Cement Production Process Read More » 6 Tips To Make Your Cement Plant More Successful equipment / By AGICO As we all know, the cement equipment Archives Cement PlantThe Leading Cement Plant Supplier from China Since our company was founded in 1997, we have never stopped the research in the field of cement production technology and cement equipment design Over the past 20 years, our engineers and construction team have successfully built hundreds of cement plants for customers around the planetCement Plant for Sale Cement Plant Equipment Design

Cement Plant, Cement Equipment Cement Plant Manufacturer

Cement plant is necessary for cement production, mainly consist of a series of cement equipment apply for preparation of cement raw materials, clinker production, and finished cement production, such as cement mill, cement crusher, rotary kiln, cement roller press, cement dryer, clinker cooler, cement silo, and related cement plant equipmentFrigate Teknologies Pvt Ltd is a leading manufacturer and supplier of Cement Plant Equipment in India A1550, 2nd Floor, Green Field, Faridabad +91 987 188 8647Cement Plant Equipment Manufacturer and Supplier in Firstly, our cement plant equipment is made of advanced technology and highquality materials, with very low failure rate and relatively low maintenance cost Secondly, the energy consumption and power consumption during the operation of cement plant and the resource waste are relatively low Therefore, the total production cost of this cement Cement Plant Cement Manufacturing Plant EPC Project

Cement Plant Manufacturers, Cement Plant Equipment

Cement Plant Manufacturers: We are Leading Cement Plant Manufacturers, Industrial Equipment Manufacturer Suppliers Contact us for Cement Plant Upgradation, Material Handling Equipment Call us at +91 for Turnkey Plant ManufacturingWe are the manufacturer equipment supplier of Cement Plants, Lime Plants, Paper and Pulp Plants We also provide turnkey solutionsSupplier of Cement Plant l Lime plant l Paper Pulp Plant Cement Plant Manufacturers Cement Plant We manufacture and supply all type of Cement Plant Machines and process equipment like Cement Plant Crushers, separators, vertical rollers, kiln and shells, bucket and chain belts etc The objective of Cement Plants Equipments is to improve the product quality The raw material used in cement plants are sand, clay, limestone, What are equipments used in a cement plant Manufacturer

cement plant equipments manufacturer and suppliers of

Ashoka's cement plant unit has continued focused on objectives of product improvement and quality In our entire turnkey cement plant equipments and machinery, we supply a complete assembly consisting of different machines and equipment, which facilitate the plant to execute efficiently and manufacture a betterquality completed product as per the international quality Cement Plant Equipment Besides supplying the complete cement plants on turnkey basis, Chanderpur Works also manufacturing cement plant equipment such as cement ball mills, material handling equipment, Classifier and feeders etc Chanderpur Works Pvt Ltd has already supplied these cement plant equipment to some major multinational companies like Cement Plant Equipment Cement Ball Mills at Chanderpur GroupCement Plant Machinery OVERVIEW Since its inception in 1963, the Cement division of WIL has been providing reliable and robust solutions for the cement industry both in India and abroad We undertake complete responsibility for the design, engineering, manufacture, supply, project management and supervision of erection commissioning of all mechanical, electrical, Cement Plant Machinery Walchand

Cement Bulk Plant Equipments Sparklet Engineers

CEMENT BULK PLANT EQUIPMENTS CEMENT BULK PLANT EQUIPMENTS Bulk Handing Equipment Batch Mixers Mobile Bulkers Twin Pod Filtration Unit Cementing Surge Tank Pump Motor Skid Download brochure BULK HANDLING EQUIPMENT BATCH MIXERS Sparklet make Batch Mixer’s are self contained, cement mixing unit, designed to perform critical mixing Some largescale equipment in the cement plant, such as vertical roller mill, cyclone preheater, rotary kiln, etc, has a complex structure and takes a long time to manufacture, so they must be ordered in advance according to the schedule of the construction period to ensure that they will arrive in time during the installation The supplier of each type of equipment should be How to Start a Cement Factory Cement Plant Equipment DesignWe are the manufacturer equipment supplier of Cement Plants, Lime Plants, Paper and Pulp Plants We also provide turnkey solutionsSupplier of Cement Plant l Lime plant l Paper Pulp Plant

Nelson Machinery International Sellers of SecondHand

Specializing in the sale of second hand cement plant equipment, and complete used cement plants In addition to used and new surplus Cement Plant Equipment (rotary kilns, ball mills, vertical roller mills), NMI deals in many other types of machinery, including used equipment for Bulk Material Handling, Crushing, Grinding, Industrial Mineral Processing, and Power Plants30/08/2012 Generally cement plants are fixed where the quarry of limestone is near bye This saves the extra fuel cost and makes cement somehow economical Raw materials are extracted from the quarry and by means of conveyor belt material is transported to the cement plant There are also various other raw materials used for cement manufacturing For example shale, fly Cement Manufacturing Process Phases Flow Chart 17/08/1971 Classification Code (SCC) for portland cement plants with wet process kilns is 305006, and the sixdigit SCC for plants with dry process kilns is 305007 Portland cement accounts for 95 percent of the hydraulic cement production in the United States The balance of domestic cement production is primarily masonry cement Both of these materials are 116 Portland Cement Manufacturing