rock crushing plant process r

2022-11-05T02:11:25+00:00

Rock Crushing Process in Mining

18/07/2015 First the rock will enter the crushing chamber and drop as far as the angle of the crushing surface will allow it to The crusher “breaks it and the fine material produced will drop through the gap between the mantle and the liner as it opens The coarse material that can’t fall through will remain to be crushed with the next gyration The speed of the crushing cycle 05/01/2012 Rock crushing process Rock crushing process involves many plants, such as jaw crusher for primary crushing stage, impact crusher for secondary crushing stages, and also other crushing plants such as cone crusher, vertical crusher, ball mill, raymond mill etcTop five Rules in Rock crushing process Stone Crusher There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences and operational experience of a number of partiesCrushing Plant Design and Layout Considerations

Crushing in Mineral Processing

26/12/2015 Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surface Less abrasive and softer rocks or stones are crushed by impact and shear but also rockprocess is an application to draw flowsheet of mineral process Define your feed, position crusher and screen, then get results Find optimum of your plant, simulate your modifications rockprocess is a mandatory tool for production manager and process engineer in aggregates and minerals industryrockprocess How simulate crushing and screening plantThe goal of the tertiary (third), quaternary (fourth) or final reduction stage of the crushing process is to size and shape rock or other material into a marketable product Again, there may be overlap between stages in terms of which crusher styles work bestTypes of Rock Crushers Quarry Crushing Equipment Kemper

Crushing plant Wikipedia

A Crushing plant is onestop crushing installation, which can be used for rock crushing, garbage crushing, building materials crushing and other similar operations Crushing plants may be either fixed or mobile A crushing plant has different stations (primary, secondary, tertiary, ) where different crushing, selection and transport cycles are done in order to preferred supplier in the rock processing industry Our highest priority and personal commitment is to provide lifetime support and service for your aggregates processing operations Whether you need a single crusher, a multistage process or a complete plant, we assist you with the right design for the most costeff ective crushing process We are the world’s Crushing and Screening Handbook10/03/2016 Crushing Plant Flowsheet DesignLayout In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made to take lumps of 2in size, but they work much more efficiently if their feed is ½ in or less Before the advent of the Symons cone crusher Crushing Plant Flowsheet DesignLayout

AP42 Section 11192 Crushed Stone Processing and

Quarried stone normally is delivered to the processing plant by truck and is dumped into a bin A feeder is used as illustrated in Figure 111921 The feeder or screens separate large boulders from finer rocks that do not require primary crushing, thus reducing the load to the primary crusher Jaw, impactor, or gyratory crushers are usually used for initial reduction The crusher Rock Crushing Plant 6 Revised 11/01/11 Applications Advice For example, the calculation for PM would be: 650 hp * 00007 lb/hphr = 0455 lb/hr 0455 lb/hr * 1500 hours per year / 2000 lb per ton = 034 TPY B Rock Processing Operations Point ID lb/hr Description Process Rate TPH Factor lb/ton Control Efficiency PM Emissions TPYROCK CRUSHING PLANT APPLICATIONS ADVICE OklahomaRock Crushing Plant Process time to get crushing rock products magazine,the latest equipment for the toughest job in the quarry crushing: rock crushing plants, cone crushing, for a single crusher operation, crusher cone 150 tph cost used mobile parker crushing plant cobalt washing plant in belize sale Rock Crushing Plant Process terrassementrauxfr

Types of Rock Crushers Quarry Crushing Equipment Kemper

The type of rock you plan to focus on processing in your operation will dictate the types of rock crushers you’ll need to include in your crushing circuit The more you know about the type of rock you wish to crush and what its enduse will be, the easier it is to choose the best equipment to achieve your project goals So it can simplify the crushing process, can make the three section crushing into two or one section crushing, and reduce the equipment cost of the mineral processing factory Cone Rock Crusher: This kind of portable rock crusher designed and manufactured by Aimix Group is a superior product And it uses the most advanced technology and conception Therefore, it has Rock Crusher Jaw Cone Rock Crushing Machinerock crushing and screening process simulator pdf rock crushing and screening process simulator pdfdesing of crushing plant pdf download bruno crushing plant Crushing Systems The crushing screening products within the mineral processing portfolio provide our customers with the a variety of options in developing a best in class solution to modelling simulation and rock crushing and screening process simulator pdf

CRUSHING SCREENING Crushing and Screening

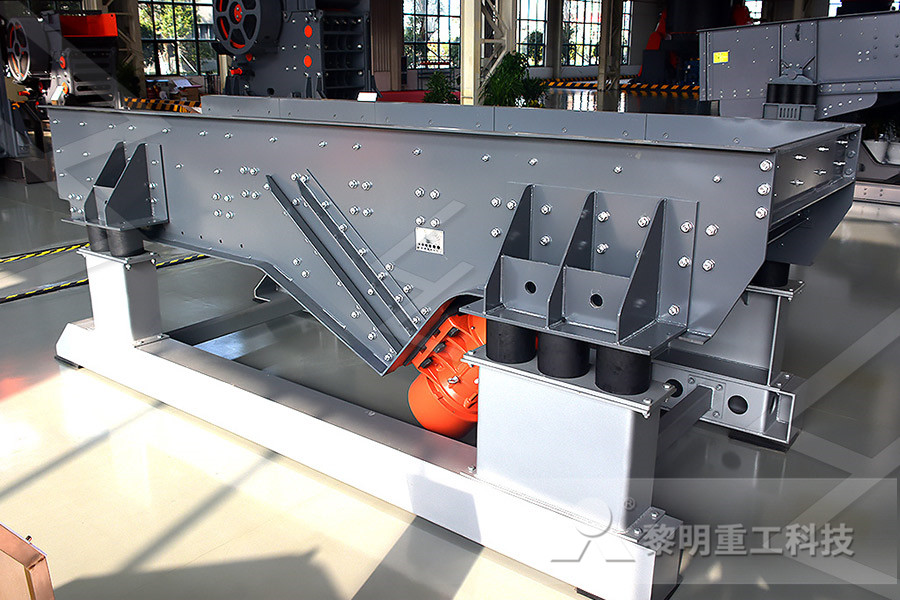

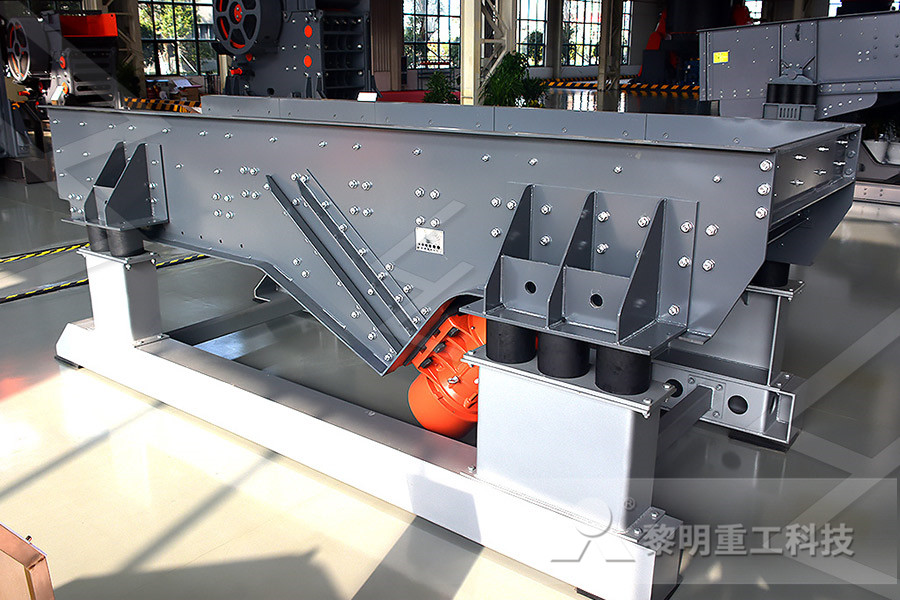

hub of every rock processing plant They are used to classify materials both in different stages of the crushing process and in final product separation Designed as a nonwelded frame with adjustable vibration features for different material types and screening sizes, Meka screens provide screening efficiency that is high quality and dependable Our screens come in various plants are used for primary crushing of bulk materials mainly in ore mines and in the n atural rock industry Today, stationary, semimobile and m (PDF) SIZE REDUCTION BY CRUSHING METHODS ResearchGate09/09/2017 As we’ve said, Aimix’s stone crushing process line(jaw crusher, cone crusher, vibrating screen, belt conveyor) was exported to Sri Lanka on August, 2017 Here, I will introduce its working process to all of you As a Working Process of Stone Crushing Process Line

AP42 Section 11192 Crushed Stone Processing and

Quarried stone normally is delivered to the processing plant by truck and is dumped into a bin A feeder is used as illustrated in Figure 111921 The feeder or screens separate large boulders from finer rocks that do not require primary crushing, thus reducing the load to the primary crusher Jaw, impactor, or gyratory crushers are usually used for initial reduction The crusher Rock Crushing Plant Process time to get crushing rock products magazine,the latest equipment for the toughest job in the quarry crushing: rock crushing plants, cone crushing, for a single crusher operation, crusher cone 150 tph cost used mobile parker crushing plant cobalt washing plant in belize sale Rock Crushing Plant Process terrassementrauxfrIntroduction: Rock Crushing plant includes vibrating feeder , jaw crusher, impact crusher or cone crusher , vibrating screen, belt conveyor and centrally electric controlling system, etc The designed capacity is from 50t/h to 500t/h To meet customer’s specific requirement, we can also add other equipment such as cone crusher , dust catcher on the crushing plant Process of Rock Crushing Plant

Aggregate Processing Plant Design

08/01/2018 The purpose of the aggregate processing plant is to prepare the rock or mineral in a form suitable for its use as aggregate, commonly defined in terms of particle size and size distribution, particle shape and mechanical properties, eg comprehensive strength As a result, the process plant usually contains only the unit processes of crushing and grinding and undergo primary crushing at the mine site before being transported to the processing plant Figure 111912 is a flow diagram for industrial sand and gravel processing The mined rock is transported to the processing site and stockpiled The material then is crushed Depending on the degree of cementation, several stages of crushing may be 11191 Sand And Gravel Processing US EPASo it can simplify the crushing process, can make the three section crushing into two or one section crushing, and reduce the equipment cost of the mineral processing factory Cone Rock Crusher: This kind of portable rock crusher designed and manufactured by Aimix Group is a superior product And it uses the most advanced technology and conception Therefore, it has Rock Crusher Jaw Cone Rock Crushing Machine

rock crushing process costs autolavfr

Rock Crushing Plants Costs Crusher Operating Costs: How to Optimize and Reduce The approximate running costs for crushing plants of different capacities up to 4,000 tons per day on the basis Crusher Operating Costs: Mini Rock Crushing Process Costs Annette Haag Dekorationen Rock Crushing Process Costs Customer Case Crushing processing hub of every rock processing plant They are used to classify materials both in different stages of the crushing process and in final product separation Designed as a nonwelded frame with adjustable vibration features for different material types and screening sizes, Meka screens provide screening efficiency that is high quality and dependable Our screens come in various CRUSHING SCREENING Crushing and ScreeningJaw crushers are an excellent primary crusher when used to prepare rock for subsequent processing stages Cone and gyratory crusher These are also compressiontype machines that crush material between a moving and a stationary piece of steel The setting between the two pieces controls the output Although the chamber is round in shape, the moving piece of steel Rock crushing equipment for sale Eastman Rock Crusher