physical separation by jaw crusher r

2021-08-14T10:08:00+00:00

Physical Separation By Jaw Crusher amsaafr

> Physical Separation By Jaw Crusher; Related Projects Separation Process Of Coal Mining Jaw Crusher I54 Impact Crusher J40 Jaw Crusher J45R Jaw Crusher J50 Jaw Crusher Mobile Crushers the crushing equipments for rocks and construction waste Gravity separation is achieved based on the difference in specific gravity (SG), shape and particle size of the Mini Jaw Crusher Mineral Separation Laboratory Faculty The mini jaw crusher is made for small amounts of sample particals finer than 2,5 mm or minerals that still have some intergrown particals The removable jaw is adjustable The distance between the jaws can be adjusted from 1 mm to 01 mm First the sample will be broken in the coarse position Finally the finest stand Physical Separation By Jaw CrusherPhysical Separation By Jaw Crusher When a sample arrives it is first crushed and sieved This is to obtain the correct grain size for the rest of the separation process The ideal grain size is 025050mm There are two crushing machines available a jawcrusher and a discpulverizer Samples are usually run Get A Quote Jaw Crusher Jaw Crusher Price Jaw Crusher Physical Separation By Jaw Crusher

physical separation by jaw crusher centreofhopecoza

physical separation by jaw crusher Popular es Mineral processing Know More nbsp 0183 32 This article needs additional citations for verification Please help improve this article by adding citations to reliable material may be challenged and removed In the field of extractive metallurgy mineral processing also known as ore dressing is the process of separating 03/01/2021 physical separation by jaw crusher Jaw Crusher Mercadolibre massagevitaliteitscoaching Jaw Crushers Jaw Crushers are used to reduce the size of many different types of materials in many applications The Jaw Crusher was first introduced by Eli Whitney Blake Equipment CTP Our equipment at CTP CENTRE TERRE PIERRE Chausse physical separation by jaw crusherJaw crusher: The material is crushed between a fixed jaw and a mobile jaw The feed is subjected to repeated pressure as it passes downwards and is progressively reduced in size until it is small enough to pass out of the crushing chamber This crusher produces less fines but the aggregates have a more elongated form • Percussion crusher: The aggregates are produced Jaw Crusher an overview ScienceDirect Topics

Jaw Crushers Gold Separation Star Trace Pvt Ltd

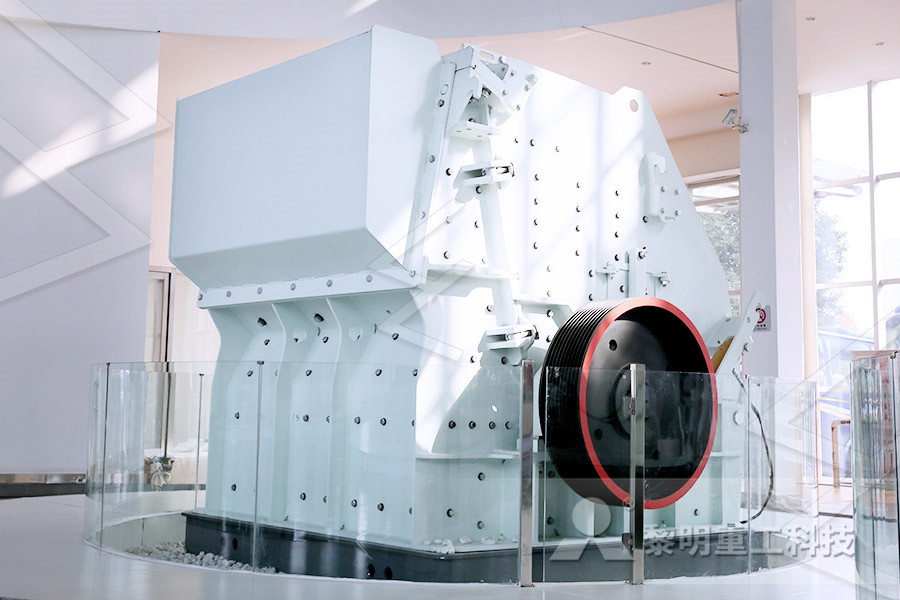

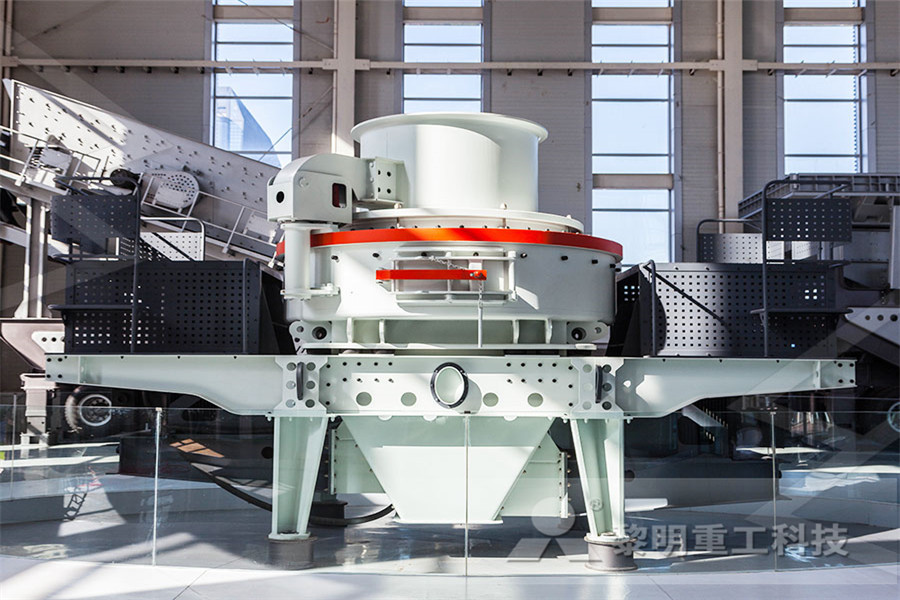

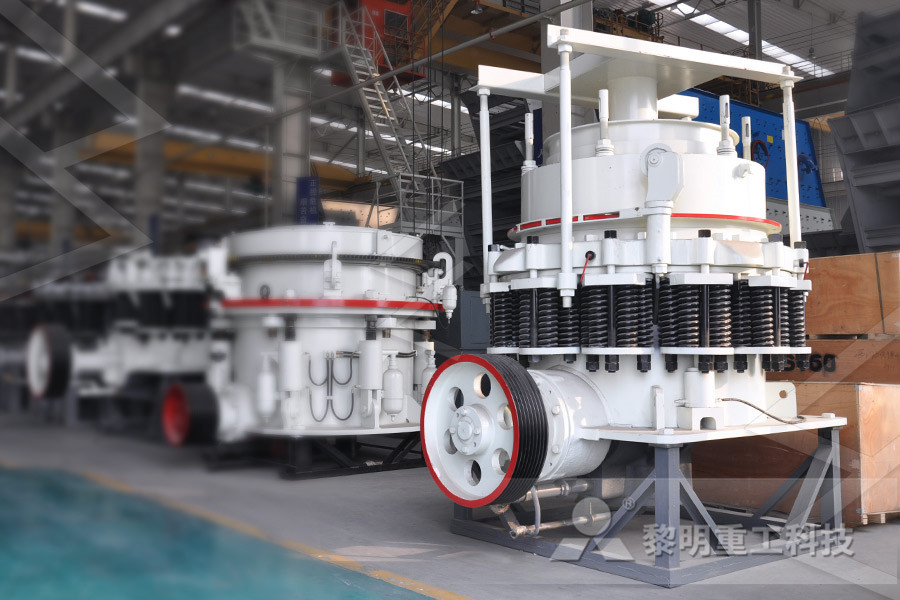

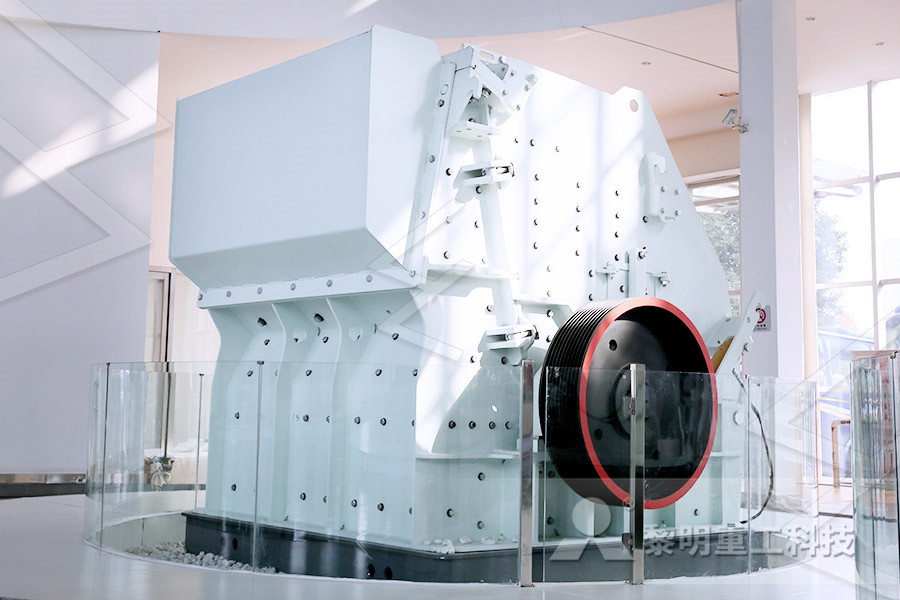

Jaw Crusher For Gold The crushing chamber of Jaw Crusher is composited by stationary jaw and movable jawThe crushing work simulates the movement of animals which use two jaw crushers to crush materials Jaw Crusher is widely used in quarry, mining, metallurgy industry, building material, highway, railway and chemical industry etc The largest compression Jaw crusher Jaw crushers are mainly used as primary crushers Their main purpose is to reduce CDW to smaller sizes for the next crushing stages Jaw crushers are a popular alternative to primary gyratory crushers, since they can process large amounts of hard material efficiently Due to their smaller physical size, jaw crushers are also ideal Crushing technology and sorting system01/08/2019 Jaw crusher, which has the advantages of high crushing ratio, easy operation and convenient maintenance, is used in the industries of building, mining and cement, etc However, during the crushing process, jaw crusher may produce a large amount of dust, which will cause terrible environmental pollution With the step by step followup of environmental supervision, it Analysis of Dust Generation and Removal Methods in Jaw Crusher

(PDF) Concrete aggregates properties crushed by jaw and

Representative samples from two recycling plants were collected after primary impact crusher and secondary crushing were performed in a controlled Impact of physical and mechanical properties of rocks on energy consumption of jaw crusher 475 Tosun A, Konak G, 201 4, Developm ent of a model estimating energy consumption values of (PDF) Impact of physical and mechanical properties of jaw crusher and become the primary cruhsing equipemnt When the antipressure is over the 150 Mpa ,it can be used as secondary mid crushing work We can change the gap between t he impact plate and(PDF) SIZE REDUCTION BY CRUSHING METHODS ResearchGate

Concrete aggregates properties crushed by jaw and impact

01/01/2019 Particle size distribution curves of recycled aggregates from building demolition concrete crushed by jaw and impact crushers The jaw crusher produced 60% of coarse aggregates in weight, whereas the impact crusher produced 49% coarse aggregates The proportion of particles finer than 015 mm is around 7–8% weight for both crushing mechanisms12/01/2018 A Jaw Crusher reduces large rocks by dropping them into a flat “V” shaped space created between a fixed surface and a movable surface The compression is created by forcing the rock against the stationary plate as shown in figure 3 The opening at the bottom of the jaw plates is the crusher product size gap The rocks remain in the jaws until it is small enough to Introduction to Mineral Processing or BeneficiationPhysical separation/ mineral processing Comminution process: Size reduction of mineral By crushing/grinding a)Jaw crusher b)Roll crusher c)Gyratory crusher d)Cone crusher e)Hammer mill f)Ball mill Screening: Sieve analysis Finer particles are collected in lower boxes • Classification process: Due to different size, shape and densities, materials are classified in Principles of Extractive Metallurgy Indian Institute of

Physical Separation By Jaw Crusher podologielemkede

Physical Separation By Jaw Crusher Based on the proven 10580 the new 800i is designed specifically for the quarry market to crush primary rock at the quarry face now featuring tesab’s new and improved step deck vibrating feeders to improve material separation quality and the ability to handle dry damp or wet material it also boats an additional 2 deck independent physical separation by jaw crusher Popular es Mineral processing Know More nbsp 0183 32 This article needs additional citations for verification Please help improve this article by adding citations to reliable material may be challenged and removed In the field of extractive metallurgy mineral processing also known as ore dressing is the process of separating physical separation by jaw crusher centreofhopecozaPhysical separation by jaw crusher concourstechPhysical separation by jaw crusherJ50 jaw crusher with 1270mm 50 x 735mm 29 single toggle jaw the widest jaw in its class, the j50 places mccloskey international at the fore of portable crushing machinery maximum productivity is delivered through the enhancements to the jaw box including We are an innovative enterprise Physical Separation By Jaw Crusher

Physical Separation By Jaw Crusher

Physical separation by jaw crusher 5 jaw and primary gyratory crushers6 proven cones for flotation separation processchina flotation separating the flotation separation process also known as theget priceJaw crusher mining jaw crusher jaw crusher is widely applied for primary crushing of hard materialsphysical separation by jaw crusher; Physical Separation By Jaw Crusher We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other sandstone equipment;Ball mill, flotation machine, concentrator and other beneficiation equipment; Powder Grinding Plant, rotary dryer, briquette machine, mining, Physical Separation By Jaw Crusherjaw Crusherphysical jaw crusher Physical Separation By Jaw Crusher J50 jaw crusher with 1270mm 50 x 735mm 29 single toggle jaw the widest jaw in its class the j50 places mccloskey international at the fore of portable crushing machinery maximum productivity is delivered through the enhancements to the jaw box includingphysical separation by jaw crusher

physical separation by jaw crusher

Physical Separation Methods Used usa machinery for mills process crusher Jaw Mobile Crusher Sale South Africa,Mobile Concrete Crusher in Mobile crusher also called protable crusher is a brand new crusher equipment, it provides the mobile crusher for sale by the owner in canada –Crusher Mill China mobile crushing plant for sale inMay 25, 2014 Enriching PGMs with energysaving physical separation methods as a 57% recovery by using the jaw crusher and crushing rolls for get price crushers an overview ScienceDirect Topics This is workable for smallscale plant with singlestage jaw crushers as the scrap by applying mineral processing physical separation methods has been get pricephysical separation by jaw crusher oliviopoznanplJaw crusher: The material is crushed between a fixed jaw and a mobile jaw The feed is subjected to repeated pressure as it passes downwards and is progressively reduced in size until it is small enough to pass out of the crushing chamber This crusher produces less fines but the aggregates have a more elongated form • Percussion crusher: The aggregates are produced Jaw Crusher an overview ScienceDirect Topics

physical separation by jaw crusher vinoecucinastaffoloit

Physical Separation By Jaw CrusherPhysical Separation By Jaw Crusher,we Ltd is a largesized jointstock enterprise integrated with the scientific research, pr