pulverizer for al r

2022-12-07T11:12:04+00:00

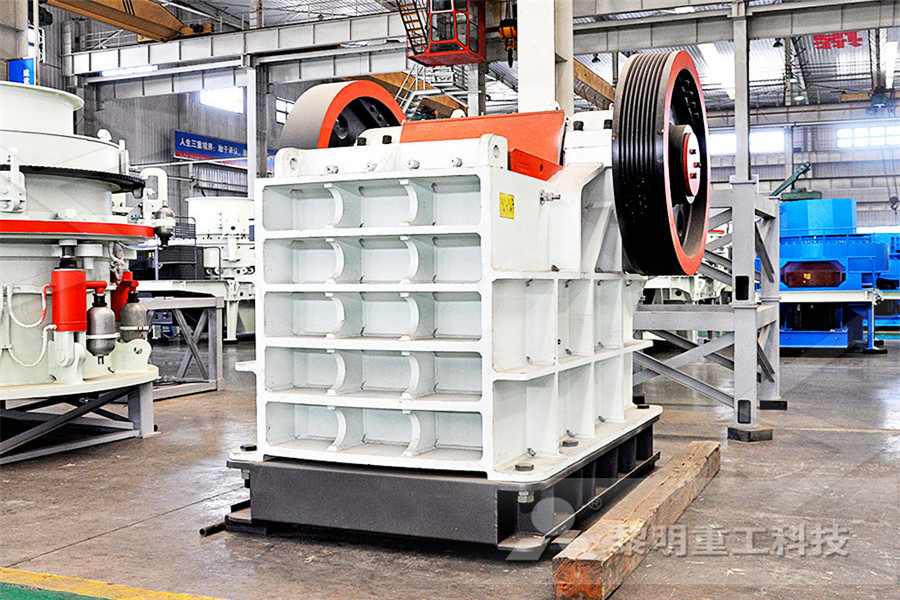

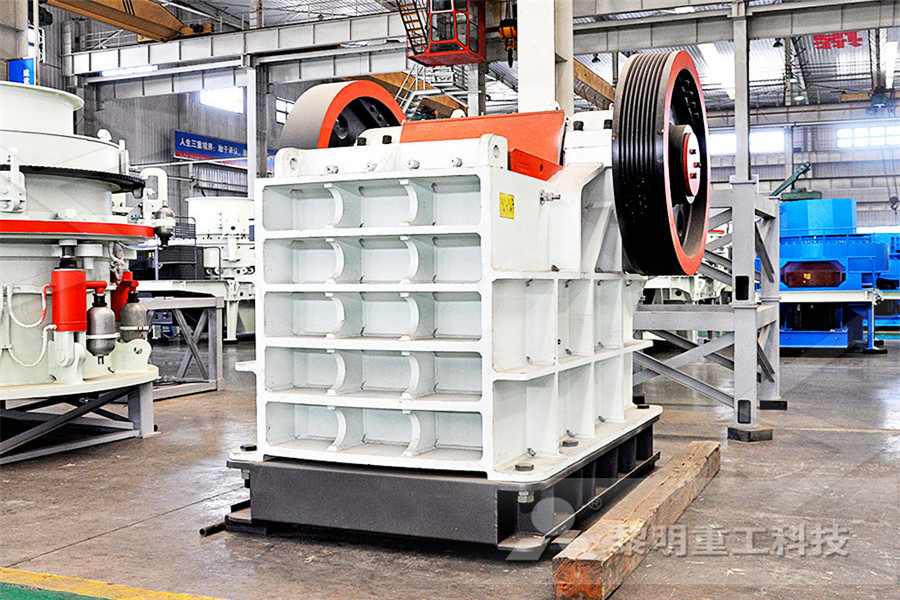

Coal Pulverizer Heavy Industries, Ltd

Pulverizers (coal pulverizer) are used to pulverize pieces of coal into fine particles (100μm) before placing into a boiler, to ensure efficient combustion Pulverizers have three functions, pulverization, drying and classification The classification function plays the important role of ensuring that only fine particles of the pulverized coal are The four most common coal pulverizers types are: BallTube Mills This type of mill consists of a rotating tube filled with cast alloy balls Coal is introduced through two hollow trunnions on each side of the tube As the tube rotates, the balls tumble onto the coal, crushing and pulverizing it Coal Pulverizer – Power Plant Pall CorporationRaw coal is fed to pulverizer from the coal feeder via a center feed pipe The coal is grounded between the three grinding rollers and the rotating table in the pulverizer Pulverized coal is simultaneously dried by the drying gas fed from bottom part of pulverizer and carried into the separator fixed at the top of pulverizer Through the separator, particle size of pulverized Coal Pulverizers an overview ScienceDirect Topics

A Comparison of Three Types of Coal Pulverizers

A TRITA Pulverizer The ATRITA pulverizer is a highspeed, compactly designed machine which reduces raw coal to pulverized coal by the combination of crushing, impact and attrition The AT RITA has separate crusher, pulverizer, and fan sections—all combined in a shopassembled package to Burr*'Coal pulverizers increase the crosssectional area and dryness fraction of coal prior to it entering a furnace Pulverized coal ignites more efficiently than raw lumps of coal, thus the overall efficiency of the furnace increases if it is fired on pulverized coalVertical Grinding Mill (Coal Pulverizer) Explained saVReeEffect of changes in pulverizer component settings on product fineness, pulverizer capacity, and power consumption This Code applies to the pulverizing system as a whole, including all the component parts necessary to take the raw coal, hot air and tempering air at the system inlet, and deliver pulverized coal in proper mixture with air and/or flue gas at the desired temperature at Coal Pulverizers ASME

CEType Pulverizers / Mill » Babcock Wilcox

The ELtype pulverizer is a higher capacity pulverizer when compared to the original Etype pulverizer of the same size E to EL conversions have significantly improved the availability, capacity, and reliability of Etype pulverizers The ELtype pulverizer is also much less prone to coal dribble problems due to an improved bottom grinding ring and throat configuration The E Reliable coal pulverizer performance is essential for sustained fullload operation of today's power plants An effective pulverizer must be capable of handling a wide variety of coals and accommodating load swings in utility boilers as large as 1,300 MW BW's pulverizers, found at power stations throughout the worldLeading Coal Pulverizers and Mills Babcock Wilcoxthe pulverized coal from the pulverizer section through the coal pipes to the burners A typical arrangement of an ATRITA pulverizer system is shown in Figure 3 AT RITA pulverizers can be designed for either pressurized or nonpressurized (suction) operation Vertical Roller Mill The vertical roller mill (VRM) shown in Figure 4 is an air swept, mediumspeed, vertical pulverizer A Comparison of Three Types of Coal Pulverizers

Pulverizers 101: Part I POWER Magazine

01/08/2011 Pulverizers 101: Part I Every coal pulverizer is designed with a particular fuel grinding capacity or throughput at a certain Hardgrove grindability index (HGI), based on a Coal Pulverizer Types (Impact, Crush and Attrition) The type of pulverizer employed depends upon requirements Pulverizers typically utilise three main types of grinding: Impact – an external force impacts with the coal This type of grinding can be compared to when a hammer hits an object eg a piece of coal Crush – the coal is forced between two bodies This type of Vertical Grinding Mill (Coal Pulverizer) Explained saVReeThe MiniPulverizer has a 1/3hp, sealed bearing motor mounted on rubber feet Operates at 115V/60Hz or 230V/50Hz Operates at 115V/60Hz or 230V/50Hz Holmes Coal Pulverizers are available in three benchtop models to reduce coal and coke from No 4 to No 60 sieve sizePulverizers for Laboratory Gilson Co GlobalGilson

Pulverised Coal an overview ScienceDirect Topics

The raw coal is then fed into the pulverizer along with air heated to about 330°C (650°F) from the boiler As the coal gets crushed by the rolling action, the hot air dries it and blows the usable fine coal powder out to be used as fuel The powdered coal from the pulverizer is directly blown to a burner in the boiler The burner mixes the powdered coal in the air suspension with additional The Coal Pulverizer plant was commissioned on 30thNov 2016 and is running efficiently till date Produces 6070% 200 mesh coal fines and the hammer life has been beyond compare at three months for a single set of 6 pcs The workmanship is of the highest order, zero leakage of coal ; indeed energy efficient machine! AAR KAY Industries This is to certify that we imported Khalsa Coal Pulverizing Plants – Khalsa Coal Pulverizer Pulverizer spillage describes the condition when raw or partially pulverized coal passing over the edge of the bowl falls through the vane wheel or pulverizer throat to be rejected through the pyrite chute No or miniscule amounts of coal should be discharged through the pyrite chute As it name implies, the pyrite chute is for discharging pyrites and tramp iron The term “pyrites” Raw Coal Spillage Or “Pyriting”

Pulverizer (Thermal Expansion 5) Feed The Beast Wiki

This page is about the Pulverizer added by Thermal Expansion 5 For other uses, see Pulverizer The Pulverizer is a machine added by Thermal Expansion 5 It is used to turn a block of ore into two of its respective Dusts The Dusts can then be smelted in any type of Furnace to produce Ingots at a 1:1 ratio It has a chance of giving a secondary output, which varies The Pulverizer is a machine added by Thermal Expansion It smashes blocks and items and pulverizes Ores into twice as much dust Pulverized ores can be cooked in the Induction Smelter, Electric Furnace, or any other furnace, to produce ingots The secondary byproduct of pulverizing only happens a percentage of the time It requires an Engine to run, or a filled redstone energy Pulverizer Feed The Beast Wiki FandomPulverizer mills act as size reduction equipment They reduce coarse materials like coal and gypsum at high speeds to tiny granules for a variety of applications Centrifugal force powers the pulverizers to grind feed materials down to the Pulverizer Machines Equipment Williams Patent

Pulverizer Optimization Components Storm

Minimum coal rejects means that your primary airflow, grinding zone, and throat areas are compatible and are operating correctly Maintaining this level of performance is important since too many rejects can pose a fire risk A Pulverizer is a mechanical tool used for smashing or grinding varied materials into tiny shreds or pieces Our Pulverizers are widely used for grinding dry and wet materials like besan, sugar, daal, herbs, leaves, spices, chili, etc Besides, they are also helpful in pulverizing coal and other related productsPulverizer Reindeer MachineryThe air sample drawn from the coal pulverizer 12 is then analyzed for percent by volume of oxygen (O 2) content and CO gas concentration in ppm (parts per million) via a known oxygen and CO gas analyzer 16 designed to operate in a harsh power plant environment and having autocalibration capabilities A suitable analyzer for this application is one manufactured by the Safety system for coal pulverizers The Babcock Wilcox

Pulverized coalfired boiler Wikipedia

The raw coal is then fed into the pulverizer along with air heated to about 650 °F (340 °C) from the boiler As the coal gets crushed by the rolling action, the hot air dries it and blows out the usable fine coal powder to be used as fuel The powdered coal from the pulverizer is directly blown to a burner in the boiler The burner mixes the powdered coal in the air suspension with Mill Inerting and Pulverizer/Mill Explosion Mitigation Richard P Stormrichardstorm@innovativecombustion (205) 4530236 2013 Annual Meeting Coal Mills are the Heart of a Coal Fired Plant Maximum capacity, reliability and performance of your operation rely on the critical roles that your coal mills Pulverizer Vibration IssuesSouthwestern Corporation designs and manufactures coal mill / pulverizer products for CE, Babcock Wilcox, Foster Wheeler, and Loesche pulverizers cable sweep Southwestern Corporation Pulverizer, Coal Mill, Coal

(PDF) Control for pulverized fuel coal mill ResearchGate

for the control purpose, it is assumed that the pulverizer mechanism in the mill is simplified and the classification operation is not included, and the coal mill is grouped into the Pulverizer spillage describes the condition when raw or partially pulverized coal passing over the edge of the bowl falls through the vane wheel or pulverizer throat to be rejected through the pyrite chute No or miniscule amounts of coal should be discharged through the pyrite chute As it name implies, the pyrite chute is for discharging pyrites and tramp iron The term “pyrites” Raw Coal Spillage Or “Pyriting”The Pulverizer is a machine added by Thermal Expansion It smashes blocks and items and pulverizes Ores into twice as much dust Pulverized ores can be cooked in the Induction Smelter, Electric Furnace, or any other furnace, to produce ingots The secondary byproduct of pulverizing only happens a percentage of the time It requires an Engine to run, or a filled redstone energy Pulverizer Feed The Beast Wiki Fandom