magnetic separation method process kenya

2023-11-26T12:11:50+00:00

Magnetic Separation, Magnetic Separation Process,

Magnetic separation is a common mineral processing method The magnetic separation process is to achieve the separation in the nonuniform magnetic field of magnetic separators according to the magnetic differences among various mineralsThe magnetic separation process is to achieve the separation in the nonuniform magnetic field of magnetic separators according to the magnetic differences among various minerals marketing@ytxinhaiMagnetic Separation, Magnetic Separation Process, Magnetic separation: based on the generation of magnetic forces on the particles to be separated, which are higher than opposing forces such as gravity or centrifugal forces This principle is used to separate ferromagnetic particles from crushed scrap mixtures • Eddy current separation: is a particular form of magnetic separation An alternating magnetic field induces electrical eddy Magnetic Separation an overview ScienceDirect Topics

A discussion of magnetic separation techniques for

Figure 1 depicts the basic magnetic separation technologies now available in the marketplace in terms of field intensities and modes of processing LIMS and scalper magnets are not detailed in this paper The selection of magnetic separation technology depends on many processing factors, including particle size, and the The manganese oxide ore process concludes ore washingjiggingstrong magnetic separation process After crushing to less than 70 mm, the ore need to be washed, sieved and classified, firstly got material with + 30 mm needs manual beneficiation, then 4530 mm ore is dressed by jig, and last ore with 45 mm should be processed by rollertype strong magnetic Differences and Applications of Magnetic Separation and The method shown in the figure is the magnetic separation method The magnetic separation process is based on the differences in magnetic properties of the ore components This method requires an electromagnetic machine which consists of a nonmagnetic conveyor belt moving over two rollers, one of which is magnetic in nature while the other is Explain the magnetic separation method with a neat

MECHANICAL SEPARATION TECHNIQUES

MAGNETIC SEPARATION Based on magnetic behavior matrial can be classified as” 1 Ferromagnetic –very strong magnetic susceptibility iron, nickel and cobalt 2 Paramagnetic –weak magnetic susceptibility – a) Weakly magnetic b) Strongly magnetic 3 Diamagnetic particles –repelled by magnet 4 Non magnetic These minerals can be separated by wrapping the poles of a magnet in paper, passing the magnet over the mineral mixture The ferromagnetic minerals will stick to the magnet and may be easily separated by removing the paper covering the magnet Paramagnetic and diamagnetic minerals are not magnetic, but they differ in how they interact with a magnetic fieldMagnetic Seperation epscwustledu As with any plant process, it’s important to understand the theory behind the method, as well as how to apply it in a way that creates efficiencies and reduces costs When done correctly, magnetic separation is a simple, inexpensive method to recover minerals from host ore or remove waste from ore streams before further processingHow magnetic separation optimizes sorting and process

Magnetic Separation Technology For A

“Magnetic Separation Technology is the most important technology for any recycling industry” Magnetic Separation is the process, in which the “magnetically caused material is detached easily” by using a magnetic force From last Magnetic Separation – Simulations in Process Engineering Highgradient magnetic fishing (HGMF) is a method for the downstream processing of biomolecules such as proteins In the first step of this method magnetic Magnetic Separation • OpenLB Open source A magnetic separation method which comprises the steps of: a) bringing a vessel having a bottom end and containing a liquid suspension of magnetically attractable particles into proximity with a magnet system, by effecting vertical movement of the magnet system relative to the vessel, whereby there is formed an annular or partannular pellet Magnetic separation method Amersham International plc

MAGNETIC SEPARATION N Chakravorty

magnetic separators and the principal ferromagnetic mineral separated is magnetite (Fe304),although hematite (re203) and siderite (FeCO3) can be roasted to produce magnetite and hence give good separation The removal of "tramp" iron from ores can also be regarded as a form of lowintensity magnetic separation Nucleic acid separation is an increasingly important tool for molecular biology Before modern technologies could be used, nucleic acid separation had been a time and workconsuming process based on several extraction and centrifugation steps, often limited by small yields and low purities of the separation products, and not suited for automation and up Magnetic particles for the separation and purification of Magnetic separation takes advantage of differences in the magnetic properties of minerals Minerals fall into one of three magnetic properties: ferromagnetic, paramagnetic and diamagnetic Ferromagnetic minerals are themselves magnetic (ie, magnetite and pyrrhotite) and can be easily separated from other minerals with a magnet since they will Magnetic Seperation epscwustledu

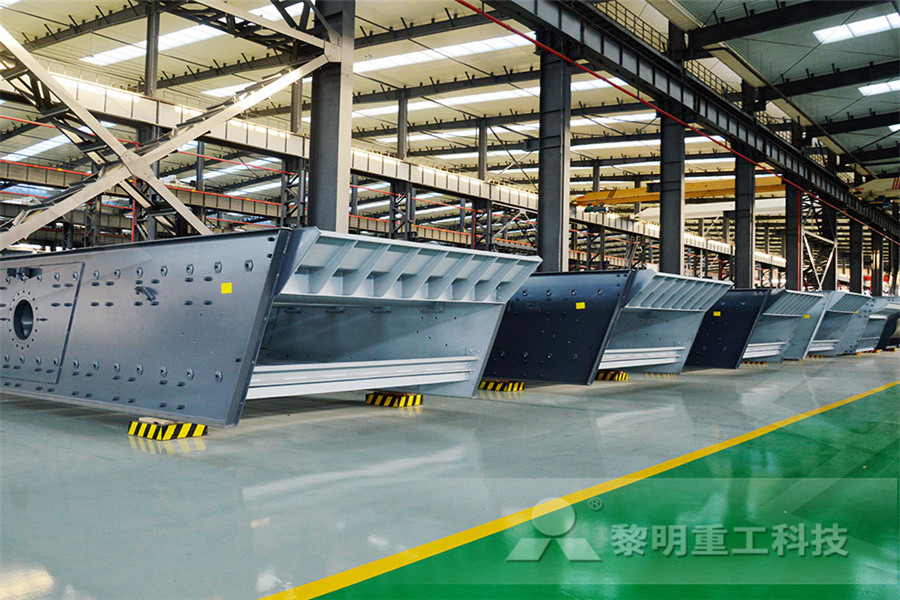

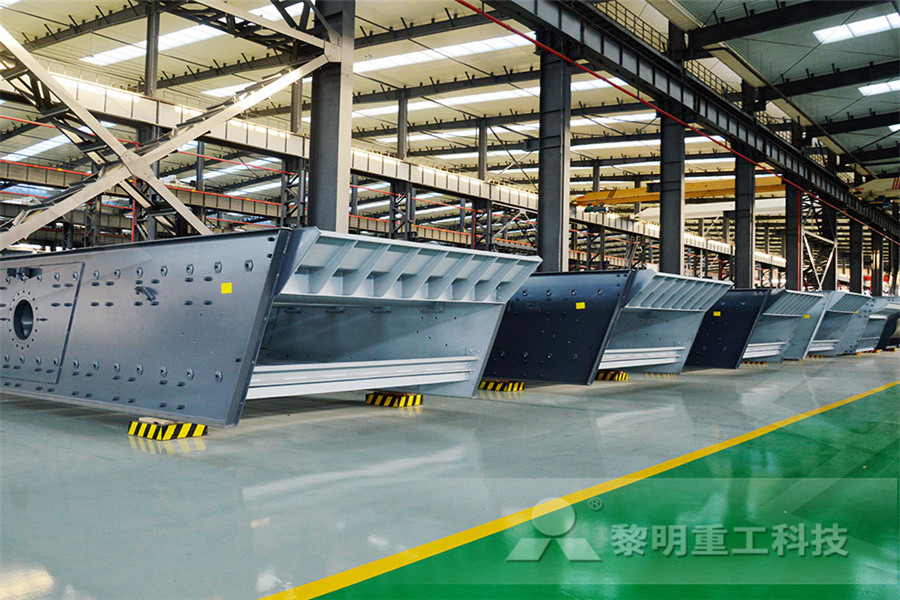

Magnetic Separators For Mineral Process Bunting

Magnetic separators can be found in most mineral processing operations, especially those processing nonmetallic minerals and magnetic ores This article investigates the use of high intensity magnetic separators and magnetic separation equipment in the minerals sector with a focus on processing dry materials (in the 15mm, +45 micron size range) Separation on conveyor (dry) Separation by magnetic drum (dry) Separation by suspended separator (dry) A magnetic pulley is used A magnet is suspended over the conveyor A plate magnet is installed on the discharge side of a conveyor A grid type magnet is installed on the discharge side of a conveyorMAGNETIC SEPARATORS kaneteccojp tire mixedcell population into a magnetic field They respond to separation processes through the interaction with spacevarying magneticforce, providing a separationalternative to centrifugation, columns, filtration, or precipitation Within the context of magnetic cell separation technologies, the tubebased method offers distinct adThe basic guide to magnetic bead cell separation Sepmag

Methods of Separation Learn Various

Magnetic separation is the process of separating components of mixtures by using magnets to attract magnetic materials The process that is used for magnetic separation detaches nonmagnetic material with those that are Magnetic separation is the main processing technology, cooperating with gravity separation, flotation, roasting magnetic separation as joined process method Strong Magnetic Iron Ore Processing Technology It is mainly used for lowgrade magnetite ore As for the strong ore magnetism, easy to grind and separate, the coarsegrained magnetite Magnetic Separation, Magnetic Separation Process, magnetic separators and the principal ferromagnetic mineral separated is magnetite (Fe304),although hematite (re203) and siderite (FeCO3) can be roasted to produce magnetite and hence give good separation The removal of "tramp" iron from ores can also be regarded as a form of lowintensity magnetic separationMAGNETIC SEPARATION N Chakravorty

Magnetic Separation • OpenLB Open source

Magnetic Separation – Simulations in Process Engineering Highgradient magnetic fishing (HGMF) is a method for the downstream processing of biomolecules such as proteins In the first step of this method magnetic A magnetic separator applies basic magnetic principles to remove ferrous based and paramagnetic metals from a range of substances including powders, granules, liquids, pellets or pastes They are usually installed within the product stream at key HACCP or inspection points See our guide to selecting the right Magnetic SeparatorA Guide to Magnetic Separation Eclipse MagneticsMagnetic separation technology To ease and accelerate nucleic acid isolation based on magnetic particles, and to offer the user a highly flexible and reliable automation, chemagen has developed a unique separation method together with the Forschungszentrum Karlsruhe GmbH The isolation of nucleic acid molecules is achieved through their Magnetic separation PerkinElmer For the Better

Magnetic particles for the separation and purification of

Nucleic acid separation is an increasingly important tool for molecular biology Before modern technologies could be used, nucleic acid separation had been a time and workconsuming process based on several extraction and centrifugation steps, often limited by small yields and low purities of the separation products, and not suited for automation and up Magnetic separators can be found in most mineral processing operations, especially those processing nonmetallic minerals and magnetic ores This article investigates the use of high intensity magnetic separators and magnetic separation equipment in the minerals sector with a focus on processing dry materials (in the 15mm, +45 micron size range)Magnetic Separators For Mineral Process Bunting Then the new integrated method of extraction–derivatization–magnetic separation was successfully applied for the target isoquinoline compounds from Coptis chinensis for the first time on the basis of the above studies, and the recovery of various samples was in the range of 9685–1014% As the key operation in the whole process A new integrated method of magnetic separation of

Sieving , Magnetic Separation Class 6,

(4) The method of sieving is also used to separate similar objects of different sizes The cashew nuts of different sizes are separated in cashew nut factories by the process of sieving Magnetic Separation Magnetic separation Separation on conveyor (dry) Separation by magnetic drum (dry) Separation by suspended separator (dry) A magnetic pulley is used A magnet is suspended over the conveyor A plate magnet is installed on the discharge side of a conveyor A grid type magnet is installed on the discharge side of a conveyorMAGNETIC SEPARATORS kaneteccojp