crusher safety equipments r

2023-05-05T12:05:40+00:00

7 Crusher Equipment Safety Tips Multico

04/01/2021 What are the crusher equipment safety tips? Train operators about crusher safety Keep instruction manuals nearby Wear PPE at all times Operate within the crusher’s capacity Be consistent with crusher maintenance Keep the crushing area clean Crushers are heavy equipment capable of breaking big rocks into smaller aggregatesThe crushing equipment's operation becomes more automatic because it uses the devices of hydraulic safety, hydraulic lock, hydraulic adjustment, hydraulic cavity cleaning, etc Compound cone crushers are widely used in sand plant and crusher plant as secondary or tertiary crusher machine Feeding size: 80300mmsafety equipments sand crusher sand crusher machineBest safety practices around crushing equipment Portable Apr 02 2018 While the safety aspects of one piece of equipment such as a crusher are extremely important safety starts with companies that prioritize overall safety The construction materials industry is heavily regulated but regulations alone will not make managers workers crusher machine safety equipment memoiredemaisonsfr

Enhancing safety around crushers Pit Quarry

16/02/2018 Some tips to keep a safe crusher: Operate at the appropriate capacity Keep platforms and areas around the machine clean Ensure lubrication, flow, temperature, wear and pressure are monitored Another crushing plant with clear walkways that are free from debris and proper guards on moving partsJaw Crusher And Safety Equipment We are involved as the manufacturing and trading of Construction Equipments, Safety Equipments, Laboratory Equipments and many more We ensure to timely deliver these products to our clients rock crushing equipment safety check list Concrete The product range of our company comprises mobile crushing plant, jaw crusher, crusher safety equipments Jaw Crusher And Safety Equipment We are involved as the manufacturing and trading of Construction Equipments, Safety Equipments, Laboratory Equipments and many more We ensure to timely deliver these products to our clients Construction EquipmentsJaw Crusher And Safety Equipment Manufacturer from Chennai

Safe and sound: Crusher safety : Pit Quarry

14/07/2015 Concrete crushing typically involves handling plastics, PVC and rebar, and these present hazards to equipment “These don’t necessarily behave well in a crusher,” Smith says “You have the potential to rip belts; for stuff to get hung up at the bottom of the crusher06/05/2020 Newer jaw crusher models are more focused on safety and easy maintenance Hydraulic separation and individual lifting of shells are in a trend that creates a better environment for any workers onsite working with the equipment Impact crusher An impact crusher is a machine that uses striking as opposed to pressure to reduce the size of a materialDifferent types of crushing equipments Constro Facilitator20/09/2017 Tag Lines a pull cable goes the full length of the conveyor, so if pulled, the tag line kills the power and stops the crushing spread if a worker detects a dangerous situation 4 The Hydraulic Grizzly Jaw SafetyCrushing and Screening Safety is our #1 Priority

Crushing Equipment Superior Industries US Manufacturer

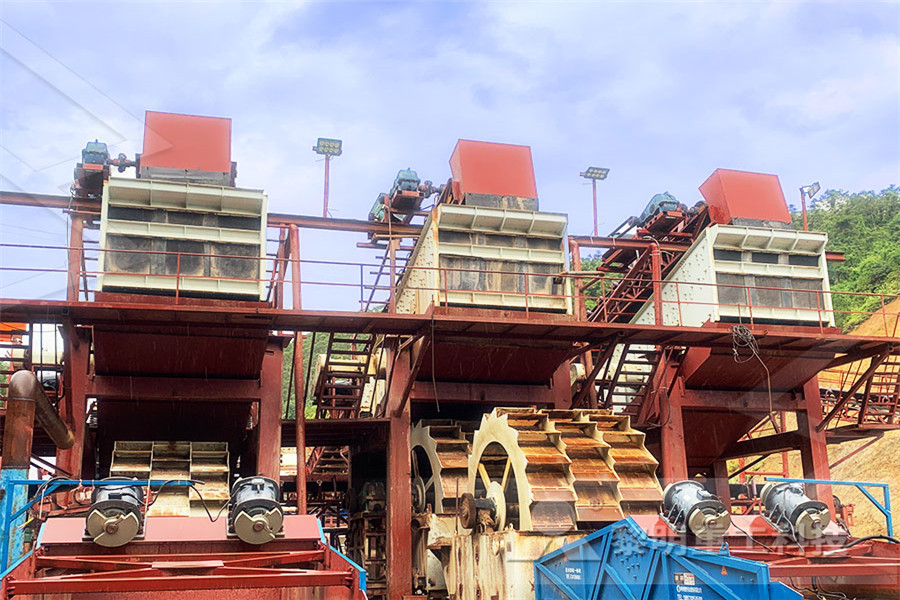

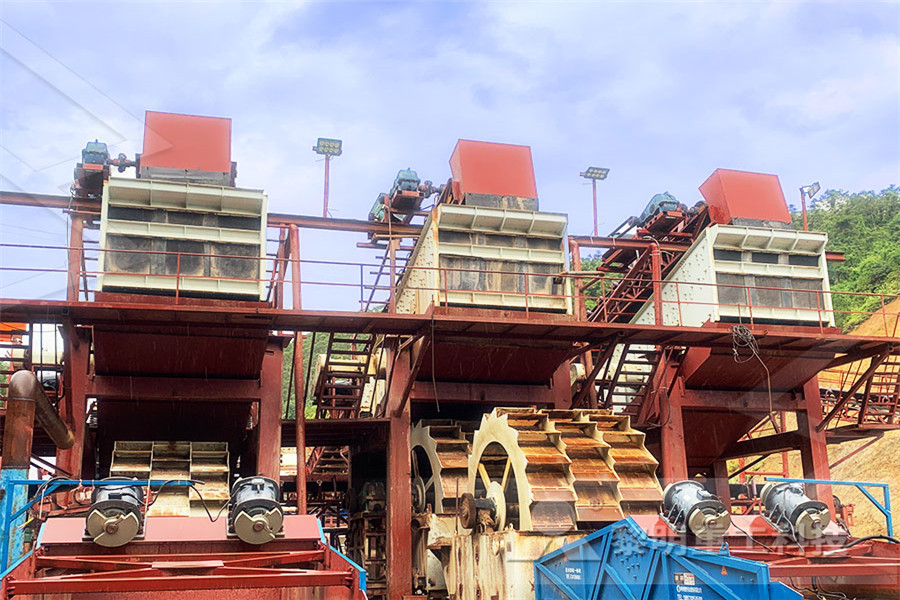

In the middle part of the 2010’s, Superior launched an aggressive strategy to improve reliability and performance of the products serving the aggregate industry Our customers — already buyers of conveyors — groaned for a better brand of service for their crushing, screening and washing equipment Superior checked the boxes and made the leapHeavy Equipment Crusher Safety Product List South dakota heavy equipment by dealer The wireless remote control system means safe operation of the crusher from the safety of an excavator or loader Dimensions o Length 94m 31 All aggregate products Red Rhino Mini Crushers come in various sizes to fit your crushing needs list safety tools equipment crusherList Safety Tools Equipment Crusher ulangThe crushing equipment's operation becomes more automatic because it uses the devices of hydraulic safety, hydraulic lock, hydraulic adjustment, hydraulic cavity cleaning, etc Compound cone crushers are widely used in sand plant and crusher plant as secondary or tertiary crusher machine Feeding size: 80300mm Capacity: 60610tph::: high end production line of safety equipments sand crusher sand crusher machine

safety equipments in a stone crusher plant

Cone crusher safety procedures Stone crushers, Jaw, Cone, Impact, Vsi crusher for Cone crusher safety procedures As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Cone crusher safety procedures, quarry, aggregate, and different kinds of minerals06/05/2020 Newer jaw crusher models are more focused on safety and easy maintenance Hydraulic separation and individual lifting of shells are in a trend that creates a better environment for any workers onsite working with the equipment Impact crusher An impact crusher is a machine that uses striking as opposed to pressure to reduce the size of a material Impact Different types of crushing equipments Constro FacilitatorBest safety practices around crushing equipment Portable Apr 02 2018 While the safety aspects of one piece of equipment such as a crusher are extremely important safety starts with companies that prioritize overall safety The construction materials industry is heavily regulated but regulations alone will not make managers workers crusher machine safety equipment memoiredemaisonsfr

list safety tools equipment crusher

heavy equipment crusher safety checklist plant greasing checklist Quarry Equipment,Stone Crusher Crusher operations safety crushing plant operation checklist safety, process crusher, the is the professional mining equipments manufacturer in the world, get price and support online amit 135 lesson 5 crushing mining mill operatorWe know that the only real measure of our worth is in the results we deliver to our customers 100+ years of experience in delivering highcapacity crushing solutions for the mining industry ensure that we provide worldclass crushing equipment, crusher parts, maintenance and optimization servicesCrushing Outotecpotential, safety, environment, and operability and maintainability INTRODUCTION The fundamental goal for the design of a crushing plant is an installation that meets the required production requirements, operates at competitive cost, complies with today’s tough environmental regulations, and can be built at a reasonable price despite the rising costs of equipment, Crushing Plant Design and Layout Considerations

Crusher Safety Manual Automotive Repair Manual

Car Manual Heavy Equipment Manual Forklift Manual Crane Manual Truck Manual Agricultural Manual Crusher Safety Manual Size : 325 MB Format : PDF Language : English Brand: Type of machine: Crusher Type of document: Safety Manual Model: Crusher Safety Number of Pages: 53 Pages Order Number: Directives on Safety and health of workers at work 89/391/ETC 89/655/ETC National health and safety regulations 2000/14/EC Noise emission in the environment by equipment for use outdoors 97/68/EC Engine exhaust emission directive 89/336/ETC EMCdirective (Electromagnetic compatibility) 97/23/EC Pressure equipment directive SAFE MACHINERY Safety standards as applied by Minerals on mobile It does not attempt to detail individual machinery safety concerns, Transport – coming in to contact with excavators loading the crusher ; Mobile crushers are versatile pieces of equipment with many uses A properly planned operation HSE Quarries Safe operation and use of mobile

Heavy Equipment Crusher Safety Checklist

Heavy Equipment Crusher Safety Checklist use a spotter when heavy equipment is in motionhis requires communication between the operator and workers to maintain safe movementlways try to walk on the driver side of equipment as the passenger side has a larger blind spotorkers should keep a safe distance from all sides of the heavy equipment while it is 27/07/2020 According to the Health and Safety Executive’s guidance for the safe operation and use of mobile jaw crushers, equipment operators may be subject to multiple risks including exposure to dust, noise, whole body vibration and being struck by objects ejected from the crusherHere's how, WEG’s premier distributor Technidrive, developed an energy efficient Improving jaw crusher safety Engineering Specifier16/07/2021 All relevant staff should consult their owner’s manual before operating Eagle Crusher equipment, or any other manufacturer’s equipment, and comply with the safety guidelines therein Serious Projects Demand Eagle Crusher Eagle Crusher consistently leads the industry in new product innovations We stand by our products with unsurpassed service The Importance of Conveyor Safety Eagle Crusher

Safety Precautions And Protective Measures For High

17/06/2020 During the high temperature in summer, the mobile crusher equipment is more prone to failure during use Therefore, you should always pay attention to the maintenance and repair of the crusher to eliminate the hidden dangers of failure While ensuring the normal operation of production, the personal safety of the equipment operator is guaranteed 24/07/2015 Jaw Crusher Safety When a crusher breaks a rock, small pieces may become airborne This is known as PLY ROCK and can be quite dangerous, especially to the eyes For this reason proper safety glasses or goggles should be worn at all times When working around crushers stay behind safety barriers, or wear a safety belt, you wouldn’t want to Jaw Crusher Safety Mineral Processing Metallurgyheavy equipment crusher safety checklist plant greasing checklist Quarry Equipment,Stone Crusher Crusher operations safety crushing plant operation checklist safety, process crusher, the is the professional mining equipments manufacturer in the world, get price and support online amit 135 lesson 5 crushing mining mill operatorlist safety tools equipment crusher

Crusher Safety Manual Automotive Repair Manual

Car Manual Heavy Equipment Manual Forklift Manual Crane Manual Truck Manual Agricultural Manual Crusher Safety Manual Size : 325 MB Format : PDF Language : English Brand: Type of machine: Crusher Type of document: Safety Manual Model: Crusher Safety Number of Pages: 53 Pages Order Number: Mobile Crushers Innovation Advantages Our mobile crusher can be used in one stage of crushing for separate operation or complete joint operations with other crushing and screening portable plants to achieve twostage, threestage or fourstage crushing, so that various crusher screening requirements could be satisfiedMobile Crushers Mobile Crushing Plant chinaAll crushers that are reconditioned are rebuilt by our own OEM factory trained crusher Please contact us during the disposal process of your surplus new or used crushing and screening equipment CMS Cepcor® OEM certified crusher technicians will safely remove the equipment from site complying with all required health and safety legislation Enquire Join our mailing Crusherscouk New Used crushers, screens feeders