mining and processing of iron r

2023-04-24T19:04:50+00:00

Mining and Processing Iron Ore Vulcan® Drying Systems

Mining and Processing Iron Ore sales@vulcandryingsystems Iron Ore’s Composition Iron ores consist mostly of iron oxides and include magnetite, hematite, limonite, and many other rocks The iron content in these ores varies from as high as 70% to less than 20% The best grades of ore contain more than 60% ironMINING AND PROCESSING: Iron ore mining can be broadly divided into two categories namely 1) manual mining which is employed in small mines and 2) mechanized mining is suitable for large iron ore mines Manual mining method is normally limited to float ores and small mines Mining of reef ore is also being done manually on a small scale The float ore area is dug up Iron Ore Mining Techniques Metal Extraction23/10/2017 Now, first of all, pure iron is rarely available (except if one or two meteorites crash) It has to be derived from iron ore that occurs near the surface when mining Then the iron derived after a long processing in the blast furnace is handed over to the iron and steel industry to make a huge amount of useful materials Most of the iron, however, is used in the The StepbyStep Process of Producing Iron from Iron Ore

iron processing Encyclopedia Britannica

iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned Included in this article also is a discussion of the mining of iron and of its preparation for smelting Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctive magnetic properties14/03/2018 When the iron ore is extracted from the mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is used to divert the fine particles for crushingThe Six Main Steps of Iron Ore Processing Multotec CanadaMining and processing of iron ore involves coarse crushing and screening Iron ore is beneficiated by crushing and then separating the iron from the gangue minerals through screening This is usually so efficient that lower grade ore can be treated especially when the magnetite is quite coarse Iron ore crushing plant iron ore beneficiation and miningProcess Flow Diagram Of Iron Ore Mining And Benifeciation

(PDF) Life cycle assessment of iron ore mining and processing

Mining of iron ore is a highly capital and energyintensive process Life cycle assessment (LCA) of the mining and mineral processing of iron ore MINING AND PROCESSING: Iron ore mining can be broadly divided into two categories namely 1) manual mining which is employed in small mines and 2) mechanized mining is suitable for large iron ore mines Manual mining Iron Ore Mining Techniques Metal Extraction01/01/2022 Mining of iron ore is a highly capital and energyintensive process Life cycle assessment of the mining and mineral processing of iron ore in Australia was carried out in this chapter using SimaPro life cycle assessment software as a case study The environmental impacts considered in the study were embodied energy and greenhouse gas emissions Life cycle assessment of iron ore mining and processing

The Six Main Steps of Iron Ore Processing Multotec Canada

14/03/2018 When the iron ore is extracted from the mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is used to divertBased on the iron ore processing experience and necessary processing tests, Prominer can supply complete processing plant combined with various processing technologies, such as gravity separation, magnetic separation, flotation, etc, to improve the grade of TFe of the concentrate and get the best yield Magnetic separation is commonly used for magnetite Iron Ore Processing Prominer (Shanghai) Mining 21/06/2018 Iron ore mining and dressing By tecscience 06/21/2018 7595 After the iron ore has been mined, it has to be processed for use in the blast furnace in order to optimize the chemical processes 1 Introduction; 2 Iron ore extraction; 3 Iron ore processing 31 Froth flotation; 32 Magnetic separation; 4 Sintering and Pelletizing; Introduction Iron is one of the Iron ore mining and dressing tecscience

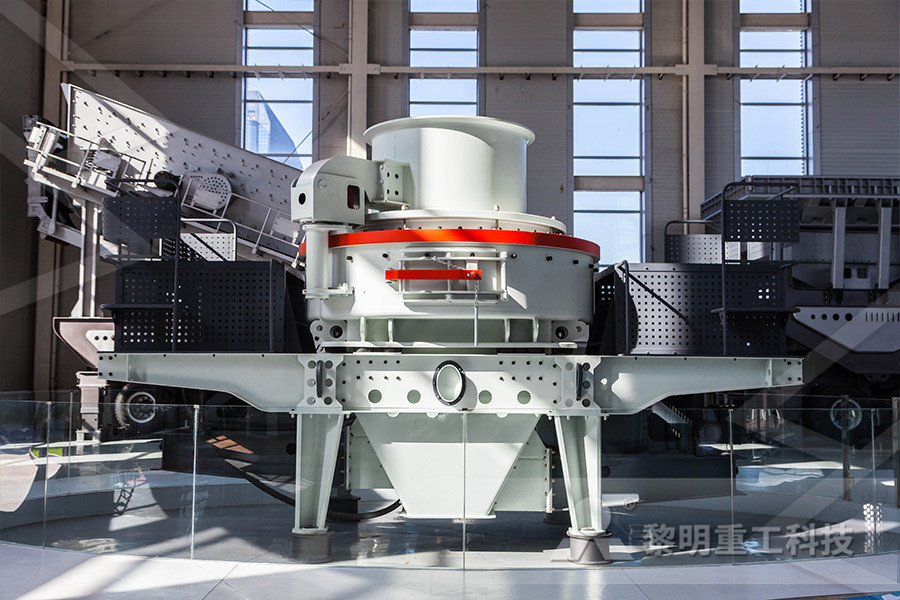

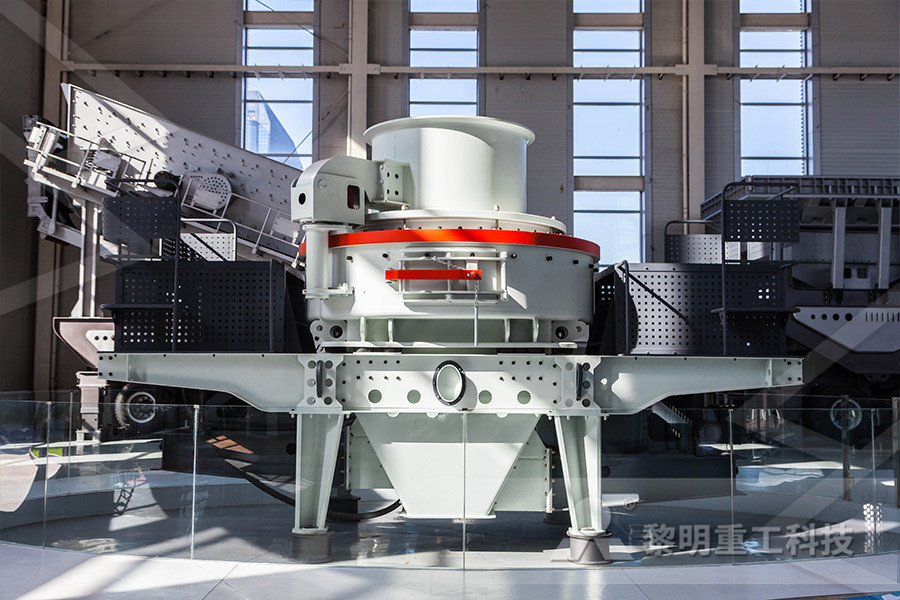

Iron or mining processing equipment Schenck Process

Iron ore mining processing Maximizing your recovery rates Contact Us Robust solutions for tough conditions The harsh environment and varied bulk material sizes in iron ore mining and processing demand technology that’s both durable and can be adjusted to your unique needs Working in close partnership with the world’s largest iron ore producers over the past 20+ Processing Of Iron Ore After Mining Modern problems of mineral processing in Russia was noted in mining of coal, nonferrous and ferrous metal ores, mining and chemical the mechanism of intensifying the process of grinding of iron ores after Chat Online Grinding Iron Ore in a Wet Autogenous Mill 8 Apr 2020 The Cretaceous plant at the Hill Annex mine of processing of mining iron fbmmenuiseriefrMining and processing of iron ore involves coarse crushing and screening Iron ore is beneficiated by crushing and then separating the iron from the gangue minerals through screening This is usually so efficient that lower grade ore can be treated especially when the magnetite is quite coarse Iron ore crushing plant iron ore beneficiation and mining Iron ore Process Flow Diagram Of Iron Ore Mining And Benifeciation

(PDF) Kenyan Iron Ore: Mining and prospects of processing

Kenyan Iron Ore: Mining and prospects of processing Prof S M Maranga* and Alvin Kiprono Bett* and Kyalo Ndeto* and Gilbert Bett** *Jomo Kenyatta University of Agriculture and Technology (Department of Mechanical Engineering) **Wanjala Mines Abstract Industrialization is one of the economic pillars in the Kenya Vision 2030 thus iron and steel will be prominent in Il y a 2 jours Sweden sparks ire of environmentalists with mining decision The Swedish government has decided to grant the exploitation of the Scandinavian country’s largest unexploited iron ore deposits to a Sweden sparks ire of environmentalists with mining 02/03/2020 At present, iron ore resources are decreasing day by day, which is characterized by more lean ore than rich ore, more associated ore and complex ore composition There are many kinds of iron ore processing technologies, What are the Common Iron Processing Methods?

Iron ore mining process and iron ore mining

Mining and processing of iron ore involves coarse crushing and screening Iron ore is beneficiated by crushing and then separating the iron from the gangue minerals through screening This is usually so efficient that lower grade ore Iron Ore Introduction: Ore, which contains an economical use of iron, is called an iron ore There are many types of iron ore, magnetite (Fe3O4), hematite (Fe2O3) and (FeCO3), etc, which are mainly used for iron making Iron ore is Iron Ore,Production Process of Iron Ore,Iron Ore 14/03/2014 Mining of Iron Ores satyendra; March 14, 2014; 0 Comments ; Hematite, Iron ore, mines, mining, Mining of Iron Ores Iron ore is a type of mineral and rock from which metallic iron is extracted economically This ore is normally rich in iron oxides and vary in color from dark grey, bright yellow and deep purple to rusty red The iron itself is usually found in the form of Mining of Iron Ores – IspatGuru

Life Cycle Assessment of Iron Ore Mining and Processing

Life cycle assessment of iron ore mining and processing 617 0 20 40 60 80 100 120 140 160 180 200 Steel Aluminum Copper (pyro) Copper (hydro) Embodied energy (MJ/kg metal)Iron in ore iron is most commonly found in the form of magnetite (Fe 3 O 4), hematite (Fe 2 O 3), goethite (FeO(OH)), limonite (FeO(OH)n(H 2 O)) or siderite (FeCO 3) Roughly 98% of iron ore on the global market is used in iron and steel production Mining and processing Common methods of extracting the iron ore consist of blasting, drilling, or general excavating, Most iron Environmental impact of iron ore mining WikipediaKenyan Iron Ore: Mining and prospects of processing Prof S M Maranga* and Alvin Kiprono Bett* and Kyalo Ndeto* and Gilbert Bett** *Jomo Kenyatta University of Agriculture and Technology (Department of Mechanical Engineering) **Wanjala Mines Abstract Industrialization is one of the economic pillars in the Kenya Vision 2030 thus iron and steel will be prominent in (PDF) Kenyan Iron Ore: Mining and prospects of processing

Mining and Processing Plants energosteel

Grinding balls of Energosteel are used in iron ore enrichment of this holding Metinvest is the largest in Ukraine and one of the largest CIS producers of iron ore raw materials and steel By results of 2013 Metinvest occupies the 25th place among the world largest steel companies according to the World Steel Association Energosteel company cooperates with all mining Iron Ore Pellets are formed from beneficiated or run of mine iron fines The iron is usually ground to a very fine level and mixed with limestone or dolomite as a fluxing agent and bentonite or organic binders as a binding agent If the ore is a Hematite ore, coke or anthracite coal can be added to the mix to work as an internal fuel to help fire the pellets This mixture is blended Iron ore pelletizing OutotecThe beginning of the Manganese ore processing involves a multistage crushing workflow From there, the production of ferromanganese, the manganese ore is mixed with iron ore and carbon and then reduced either in a blast furnace or in an electric arc furnace The resulting ferromanganese has a Manganese content of 30% to 80% Pure Manganese used Manganese Mining and Processing for Investors, Explained