Flotation Process Technology r

2022-05-05T06:05:12+00:00

Flotation Process an overview ScienceDirect Topics

Flotation In flotation process, the gas or air bubbles are introduced through culture suspension, and the microalgal biomass get attached to gaseous molecules and accumulated on the liquid surface This method is particularly effective for thin microalgae suspension that could be simply gravity thickening [38]13/09/2017 A flotation process is one method used throughout the industry to recover gold It’s a very costeffective method for concentrating gold, and is a desirable process used for the upgrading of lowsulphide and refractory ore for further gold recovery treatmentAdvancing flotation process technologies to maximise gold 17/04/2019 The froth flotation process mainly includes grinding, slurry adding, froth flotation separation and dehydration of foam products and tailing products after froth flotation Before the flotation operation, the ore needs to be ground to an optional size range by the grinding mill, generally less than 01 mon Questions About Froth Flotation Process Technology

Flotation Mineral Processing Metallurgy

11/01/2016 The FLOTATION PROCESS is one of the commonest methods of extracting the valuable minerals from certain classes of ores, and it is generally more efficient as regards the recovery of the minerals than any other process applicable Air floatation technology uses the density difference between bubble aggregates and water to remove oil droplets from water The process can be (PDF) Principles of Air Flotation TechnologyEriez Flotation provides gamechanging innovations in process technology for the mining and mineral processing industries such as HydroFloat ® for coarse particle recovery and the StackCell ® mechanical flotation cell, as well as advanced testing and engineering services, column flotation and sparging equipmentFlotation

Flotation Technologies

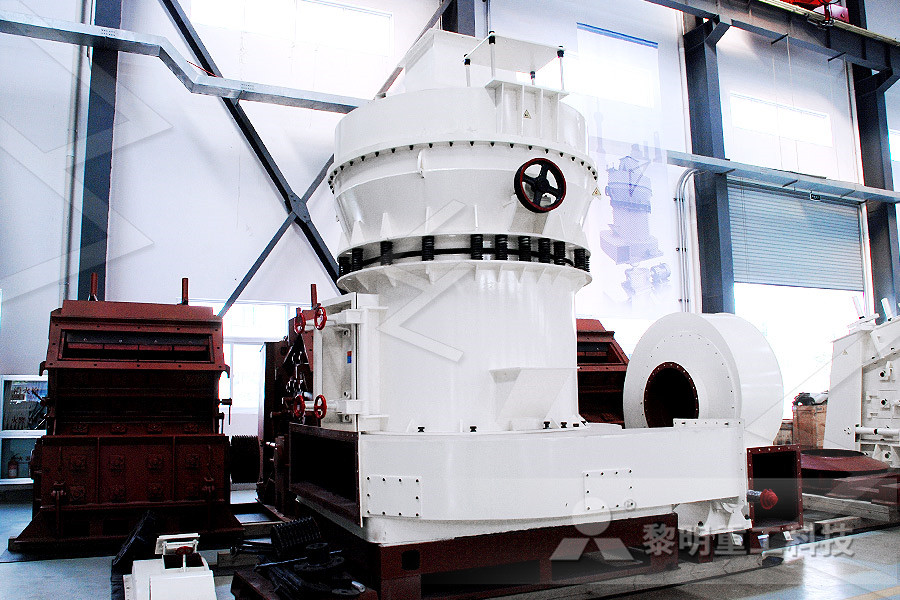

19/11/2019 Flotation Technologies Flotation Technologies in short: design, engineering, and manufacture of deepwater buoyancy systems, specializing in highstrength Flotec™ syntactic foam and polyurethane elastomer productsFlotation is an important technology in mineral processing, and flotation equipment are common chosed according to different mineral process Usually, flotation machine is applicable for the separation of nonferrous metal and ferrous metal and nonmetal, such as fluorite and talc Flotation process also called flotation separation, which is a method of separation widely Flotation Processing Technology Mining Quarry PlantFlotation Technology Handbook × Close Log In Log in with Facebook Log in with Google or Password Remember me on this computer or reset password Enter the address you signed up with and we'll you a reset link Need an (PDF) Flotation Technology Handbook Arash Ostovar

WORLD LEADER IN ADVANCED FLOTATION TECHNOLOGY

flotation technology for the mining and minerals processing industries Strengths in process engineering, equipment design and fabrication have enabled the EFD to assume a leadership role in meeting increasing global demands for minerals flotation systems Applications for EFD equipment and systems include, but are not limited to, metallic and nonmetallic minerals, is the leader in flotation technology with sound metallurgical design principles anchored in the world’s most efficient designs We have integrated the expertise of three world leaders with the addition of DorrOliver and Wemco to create the ultimate flotation technology for process specific solutionsFlotation technology DorrOliver Eimco PDF Common Questions About Froth Flotation Process Technology 16 14 07 XinHai Froth flotation is the use of the physical and chemical properties of the surface of the ore the use of chemical separation of useful ore In the process of froth flotation Get Price; Flotation System For Mineral Processing Prominer Flotation System Prominer has the ability to flotation process technology memoiredemaisonsfr

Froth Flotation an overview ScienceDirect Topics

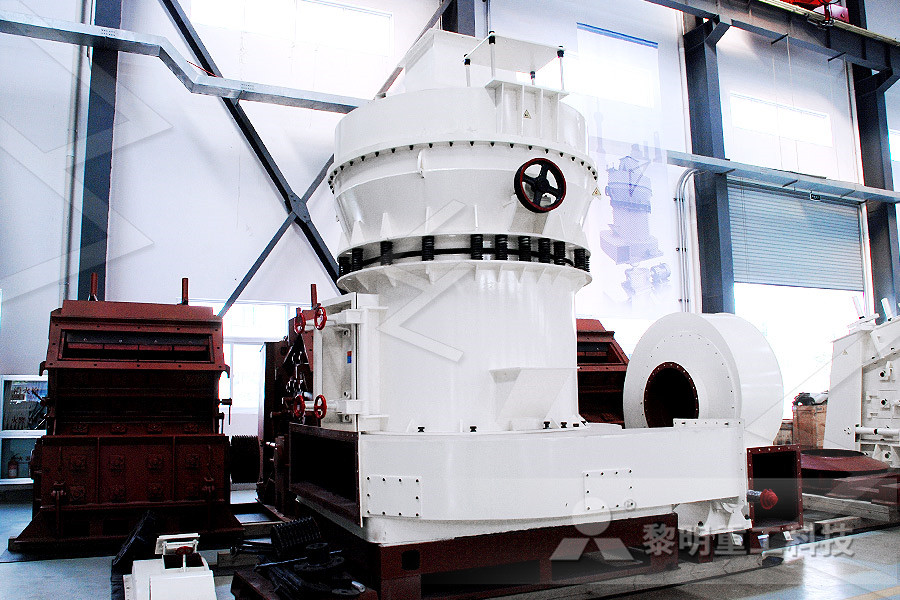

Froth flotation will remain a key unit process for the treatment of iron ores for the decades to come with the overarching challenge best described as being the need to modify and improve existing procedures and processing conditions so as to maintain an acceptable iron graderecovery response in the face of ores and feedstock that will be finer, more complex, lower in Flotation Technology • Superior Metallurgy • Higher Availability Based on sound metallurgical design principles and anchored in the world’s most efficient designs, DorrOliver Eimco has combined the expertise of two world leaders, DorrOliver and Eimco to create ultimate flotation technology for process specific solutions The result is high recovery, which DorrOliver Eimco Flotation Technologykeep process changes from producing the expected effects (Klimpel, 1995) This makes it difficult to develop predictive models for froth flotation, although work is being done to develop simple models that can predict the performance of the circuit from easilymeasurable parameters such as solids recovery and tailings solid content (Rao et al, 1995) 11 Performance Calculations 1 Froth Flotation – Fundamental Principles

Flotation Jord

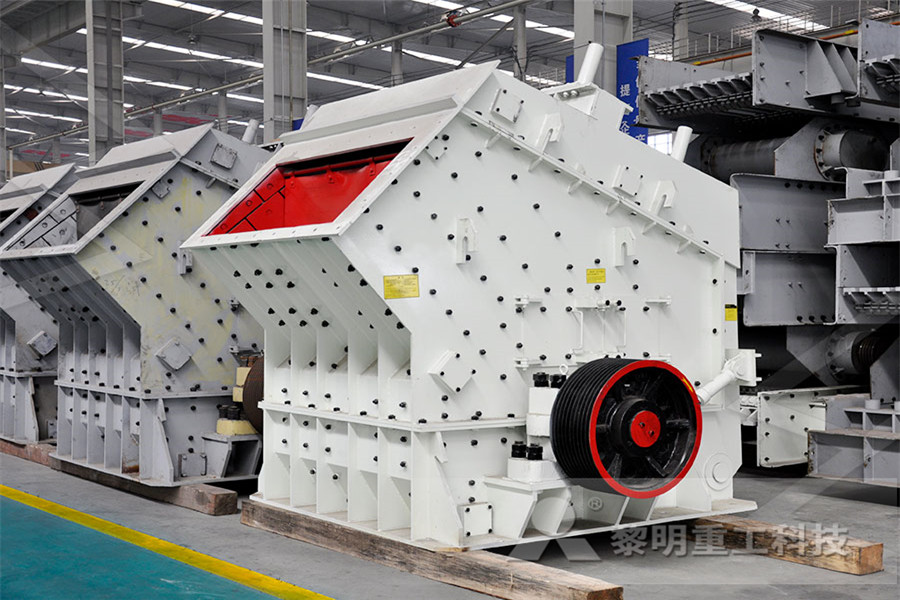

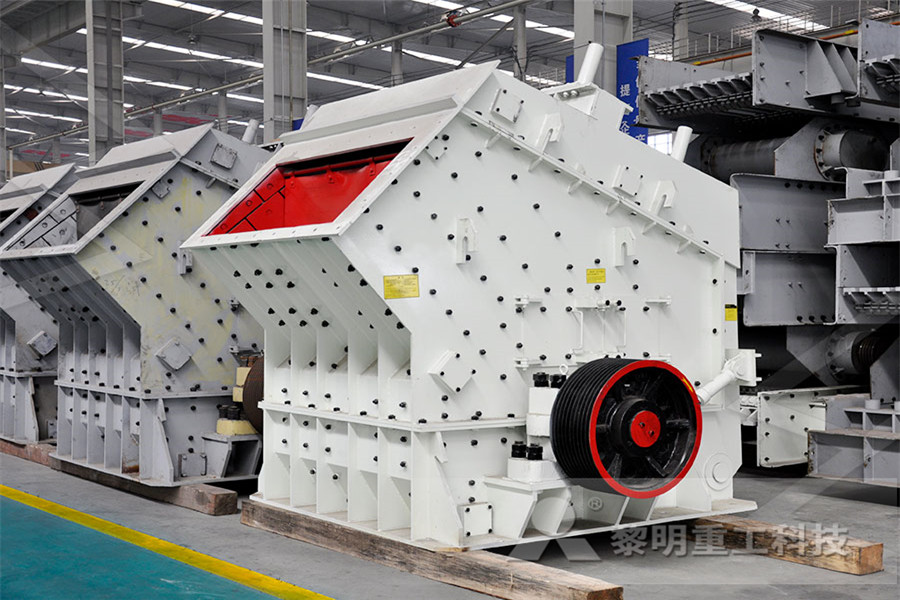

Flotation Jord Flotation Jord International’s NovaCell ™ technology provides efficient coarse and fine particle flotation in one device When implemented in beneficiation circuits, the milling energy consumption is significantly reduced (by up to 40 percent) and the water recovery is significantly enhanced due improved dewatering Gold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient Gold Processing,Extraction,Smelting Plant Design Flotation is an important technology in mineral processing, and flotation equipment are common chosed according to different mineral process Usually, flotation machine is applicable for the separation of nonferrous metal and ferrous metal and nonmetal, such as fluorite and talc Flotation process also called flotation separation, which is a method of separation widely Flotation Equipment Process Technology

Flotation Processing Technology Mining Quarry Plant

Flotation is an important technology in mineral processing, and flotation equipment are common chosed according to different mineral process Usually, flotation machine is applicable for the separation of nonferrous metal and ferrous metal and nonmetal, such as fluorite and talc Flotation process also called flotation separation, which is a method of separation widely Flotation process operating materials review reduces water treatment chemical costs by up to 30% A food manufacturer has reduced water treatment chemical consumption and sludge disposal costs by using different products in its wastewater treatment plant Read more Innovative wastewater treatment concepts water reuse and resource recovery in poultry Flotation EnviroChemie is the leader in flotation technology with sound metallurgical design principles anchored in the world’s most efficient designs We have integrated the expertise of three world leaders with the addition of DorrOliver and Wemco to create the ultimate flotation technology for process specific solutionsFlotation technology DorrOliver Eimco PDF

(PDF) Outotec® Flotation technologies Julio Alcantara

Outotec Flotation technologies 011 Outotec services improve your process performance Outotec's comprehensive technology transfer package What is more, we can make it much easier for you to can be completed with expert services and support Our fulfill current and future legislation, by ensuring that customer service operates through a global network of your plant Woodgrove Technologies is the world leader in Flotation Technology and Advanced Process Control The Direct Flotation Reactor is a paradigm shift and has taken flotation technology to a new level with an order of magnitude savings for clients on installation and operation and our Progressive Control solution will result in a significantly more stable and efficient circuitHome Woodgrove TechnologiesTHE PROCESS TECHNOLOGY The ClearFox® dissolved air flotation plant is fully automatic A helical rotor pump feeds the water from the onsite equalisation or collection tank to the reactor The wastewater flows through a pHregulation system, where pHfluctuations are adjusted Then, wastewater flows continuously into the DAF reactor Additives are mixed in a polymer Dissolved Air Flotation l ClearFox®

1 Froth Flotation – Fundamental Principles

keep process changes from producing the expected effects (Klimpel, 1995) This makes it difficult to develop predictive models for froth flotation, although work is being done to develop simple models that can predict the performance of the circuit from easilymeasurable parameters such as solids recovery and tailings solid content (Rao et al, 1995) 11 Performance Calculations Woodgrove is the world leader flotation technology and advanced process control to the mining and mineral processing industry Woodgrove has provided flotation equipment and advanced process control systems to over 200 mining operations globally Mission Vision Our Business DNA Mission Developing innovative and sustainable optimization solutions for our About Woodgrove TechnologiesFlotation deinking is a complex process A better understanding of its fundamentals would help in developing models that can predict whether a given process change would help (PDF) The Fundamentals of Flotation Deinking