mill in cement grinding station r

2023-11-10T00:11:39+00:00

Cement grinding station

16/11/2021 Cement grinding station is the final products production phase, which is formed through separating the final production phase from the whole production line During this phase, we can produceCement Vertical Mill in Cement Grinding Station Cement grinding station is a individual production device of cement last itemcomma this section will insert an suitable amount of cement clinker grinding combined resourcescomma and output of finish cement goodsinterval Cement manufacturingcomma the standard line can be divided into raw Cement Vertical Mill in Cement Grinding Station In the cement grinding process, a small amount of admixture is added to eliminate the adhesion and aggregation of the fine powder, accelerate the grinding speed of the material, improve the grinding efficiency, and also increase the content of 330μm by 1020%, which is conducive to the highquality, energysaving and highyield of cement ball mill Such additives are collectively Cement Grinding Unit Cement Grinding Plant EPC Project

Cement Grinding Plant Expert Cement Grinding Solutions

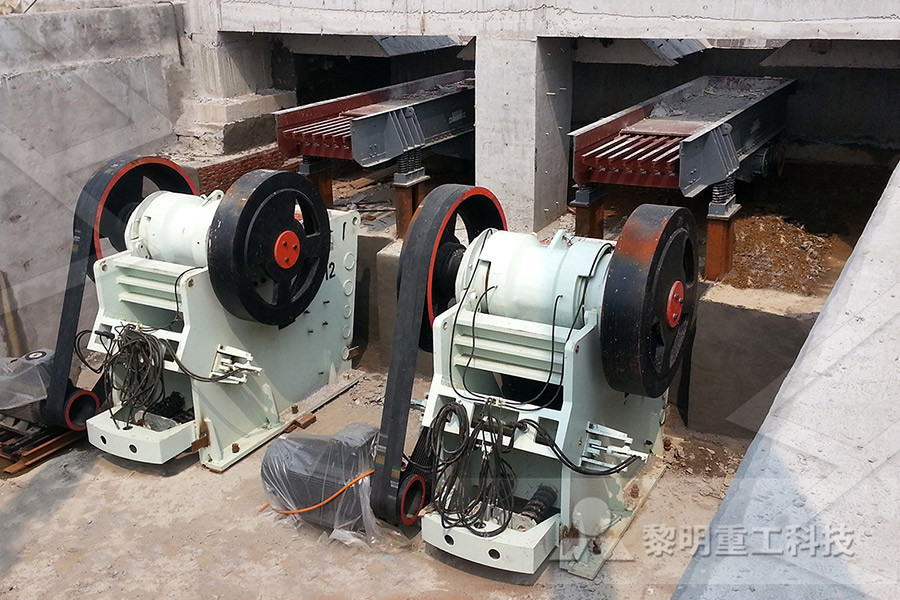

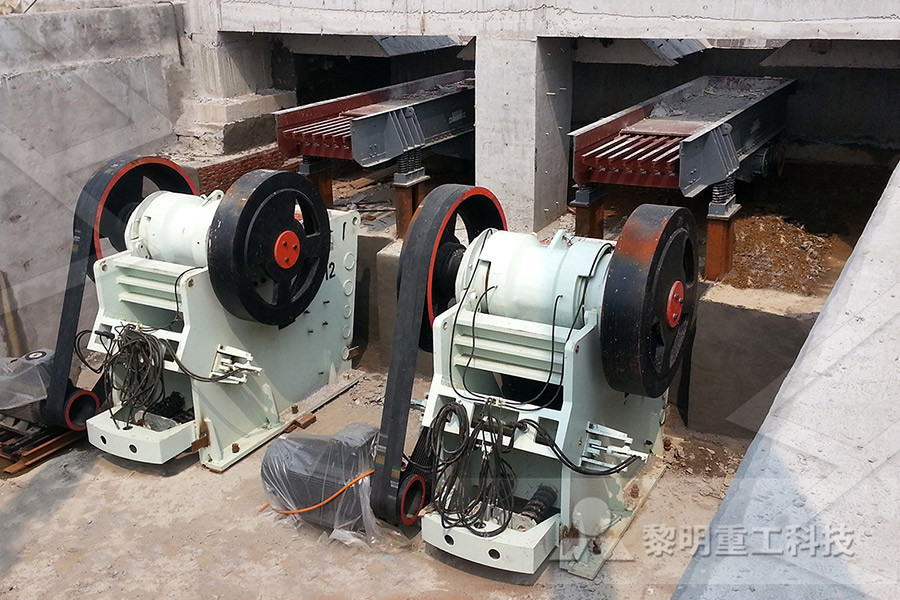

Ball mill and vertical roller mill In addition to the cement mill, other commonly used equipment in the cement grinding station include cement mill separators, bag filters and ESPs, cement silos, conveyors, bucket elevators, cement roto packers, etc cement gridning station The Systems Custom made for you The whole system of cement grinding plant mainly includes cement grinding, cement homogenization and batching, cement packaging and bulk loading And the system is composed of cement mill, OSEPA highefficiency separator, elevator, packing machine and so oncement gridning station GGBSCement Plant,cement Cement milling is usually carried out using ball mills with two or more separate chambers containing different sizes of grinding media (steel balls) Grinding clinker requires a lot of energy How easy a particular clinker is to grind ("grindability") is not always easy to predict, but large clusters of belite due to coarse silica in the feed are difficult to grindCement Milling Understanding Cement

Cement Grinding Cement Plant Optimization

Ball Mill Ball mills with high efficiency separators have been used for cement grinding in cement plants all these years Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity mills Closed circuit ball mill with two compartments for coarse and fine grinding are generally found in The cement mill housing has three parts: the lower housing, the middle housing and the housing of the separator, and they are welded into place Tension device The tension device includes a hydraulic station, hydraulic cylinder, accumulator and its pipeline The hydraulic cylinder is pressurized in both directionsCement Mill, Clinker Mill SBCCOCEMENT10/12/2019 The main working part of the cement grinding mill is a rotary cylinder mounted on two large bearings and placed horizontally The cylinder is divided into several chambers by a partition plate, and a certain shape and size of grinding bodies are installed in each chamberCement Ball Mill JXSC Machine

cement gridning station GGBSCement

Cement Grinding Station Construction Project The configuration of the Cement Grinding Station: Feeder: DEL0620 Cement mill: φ22x11m Separator: N500 Elevator: NE100x25m Customer feedback: The designers of CHANGE are Cement Vertical Mill in Cement Grinding Station Cement grinding station is a separate production unit of cement final product, this phase will add an appropriate amount of cement clinker grinding mixed materials, and output of end cement products Cement production, the general line can be divided into raw material preparation, clinker and cement made three Cement Vertical Mill in Cement Grinding Station China Raw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plantIn the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into finished Raw Mill, Cement Raw Mill, Raw Mill In Cement Plant

Cement Grinding Station For Sale

quality Cement Grinding Station zone! we are large jointstock enterprise focusing on the research,development,production and sales of intelligent mining machines learn more get quote WHAT WE DO Our product Our main product categories include cement mill,raw mill,coal mill etc Cement Mill Cement mill is also called cement ball mill, which is mainly used for 25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, metallic and concrete silos, vertical mills, horizontal mills, PLUGGRIND modular and portable grinding stations Modular and portable grinding station Plug and Grind Feed bins to mill: often 3, for clinker, gypsum and other additives, but the number can be easily adjusted Cement silos: standardized to 1,000 t each The total storage capacity to be calculated according to product portfolio and market demand Packing plant: New partnership for globbulk

Cement Mill Grinding Media Manufacturer ngzcmachinery

Product Details Cement Mill Grinding Media is delicate to cement plant It has high harness, little breakage and no malroundness It has two types Grinding balls and grinding cylpeb 1 Cement Mill Grinding Media Chemical Composition Material Chemical elements幻灯片17 4Grinding system Ball mill is the earliest grinding equipment used in cement production industry, and it still plays a leading role Although its efficiency is very low, for example, the power consumption of single particle is only 6% 9%, the maintenance of ball mill is simple and reliable, especially for cement clinker grindingCement Production Line, Cement machinery, Rotary kiln 26/09/2013 A cement grinding station can greatly digest the slag, fly ash, cinder, coal mining crusher : mining crusher always bring more value for you! « Coal Vibration Equipment for Sale,Vibration Screen Price Calcite Powder Milling Machine in Zimbabwe,Calcite Mill Supplier » Sep 26 Cement Production Line for Sale,Key Equipment in Cement Cement Production Line for Sale,Key Equipment in Cement

Project for “Cement Australia” in Port Kembla

25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, cement silos, vertical mills, horizontal mills, PLUGGRIND modular and portable grinding stations 25 años en la industria del cemento suministrando ingenieria y equipos para montaje y puesta en marcha de 16/11/2021 Cement grinding station is the final products production phase, which is formed through separating the final production phase from the whole production line During this phase, we can produce Cement grinding stationCement Grinding Plant / Grinding Unit Output Capacity: 100 ~ 5,000 TPD Grinding Mills: roller press / vertical roller mill / ball mill Grinding Systems: open circuit / closed circuit / vrm final grinding SEND INQUIRY As a leading cement plant builder, AGICO offers an expert cement grinding plant EPC serviceCement Grinding Plant Expert Cement Grinding Solutions

cement gridning station GGBSCement Plant,cement

Cement Grinding Station Construction Project The configuration of the Cement Grinding Station: Feeder: DEL0620 Cement mill: φ22x11m Separator: N500 Elevator: NE100x25m Customer feedback: The designers of CHANGE are awesome, they help us make a very good plan with low input but high outputCement Grinding Station Fill in this form or click the service online, all questions will be answered Select The Equipment Vertical roller mill Ball mill Rotary kiln Rotary dryer Cement plant GGBS plant Lime production lineCement Grinding StationSeveral energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pregrinders with ball mills Ball mills have been the traditional method of comminution in the mineral processing industries and continue to operate with old generation classifiers, their maintenance Optimization of Cement Grinding Operation in Ball Mills

Raw Mill, Cement Raw Mill, Raw Mill In Cement Plant

Raw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plantIn the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into finished The cement clinker grinding plant or cement grinding station acts as an individual production line in the last period of the cement production process in the finished product period, the cement clinker is ground by adding moderate mixing materials and then forms the finished cement adopting tube mill or vertical roller mill to producingRoller Mill Of Cement Plant nhiindiainternationalCement Gridning Station Great Wall The whole system of cement grinding plant mainly includes cement grinding, cement homogenization and batching, cement packaging and bulk loading And the system is composed of cement mill, OSEPA highefficiency separator, elevator, packing machine and so on Read More Cement Milll Separator Cyclone Air Separator In Cement Grinding Mill Separator smleducation

Clinker Grinding Station Cement Mining Equipment Supplier

Traditional clinker grinding station adopts ball mill to grind clinker, and has much dust, loud noise and high energy consumption in the process of production, it will be replaced gradually by vertical roller mill Great Wall Machinery is the professional manufacturer of cement equipment, can offer complete solution for grinding station, and improves production efficiency, reduces 25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, metallic and concrete silos, vertical mills, horizontal mills, PLUGGRIND modular and portable grinding stations Modular and portable grinding station Plug and Grind