what is st of gold ore mill r

2023-05-11T12:05:28+00:00

Cost of Stoping for Underground Mining

05/04/2017 ore is $234 The cost of transporting ore from the mine to the mill on contract is $1 per ton The milling cost of runofmine ore is taken as $285 07/09/2017 At current gold prices this is worth about US$600 Both smelter treatment charges and oxidation or bioleach costs are at least $200/t of concentrate and payables/recovery in the 90% range, so a minimum GSR for effective downstream processing is around 05 Clearly this is a function of gold price, but in the current gold price and cost environment, a good rule of Gold processing 101 Mining MagazineThese are essentially worthless, yet people are sometimes paying over $100 for chunks of this “gold ore“ Now keep in mind, this is not to say that there isn’t a collectable value to real gold ore No doubt there are many mineral collectors who enjoy collecting ore specimens and are willing to pay a premium for them, specifically from famous gold mines that are well know The key thing What is Gold Ore worth? High Grade Mining Ore

COSTS AND COST ESTIMATION Chapter NUBE MINERA

dyris approximately 250 for a mine operating on a 5 day week and 350 for a mine or mill operating continuously 7 days per week with only minor shutdowns or holidays per year 6322 personnel requirements operating costs and capital costs are influenced by the num ber of personnel required to operate the mine, mill, and services at any specific Mining Cost Service is the industry standard reference for Mining Cost Estimation This system places cost estimating data at your fingertips with conveniently indexed information to make your cost estimates faster, easier, and more credible Monthly updates assure that you are working with the most current cost data availableMining Cost Service Costmine31/05/2016 The gold contained in the ore occurs at an average of 17 opt (ounces per ton of ore) The gold is within the sulfide mineral matrix, which is not exposed (and therefore can not be dissolved by) a cyanide leach solution Also the ore contains carbonaceous matter which absorbs gold in the conventional leaching process For these reasons, The ore is considered to be Gold Ore Roasting Plant Mineral Processing Metallurgy

Gold Processing,Extraction,Smelting Plant Design

CIL is mainly for processing the oxide type gold ore if the recovery rate is not high or much gold is still left by using flotation and/ or gravity circuits Slurry, containing uncovered gold from primary circuits, is pumped directly to the thickener to adjust the slurry density Then it is pumped to leaching plant and dissolved in aerated sodium cyanide solution The solubilized gold is 31/05/2016 The overall cost of mill operation, exclusive of amortization, is generally less than 30c per ton (year 1958) Every possible operating convenience has been incorporated in the center peripheral discharge mill design On most sizes the trunnions are carried in large lead bronze bushed bearingsRod Mills Mineral Processing Metallurgycost gold digging millsOperating Costs of Gold Processing PlantMar 18, 2016The EXAMPLE Gold Mill is designed to process 500 tonnes per day of ore The flowsheets are conventional and consist of two stages of crushingcost gold digging mills fourcinqau

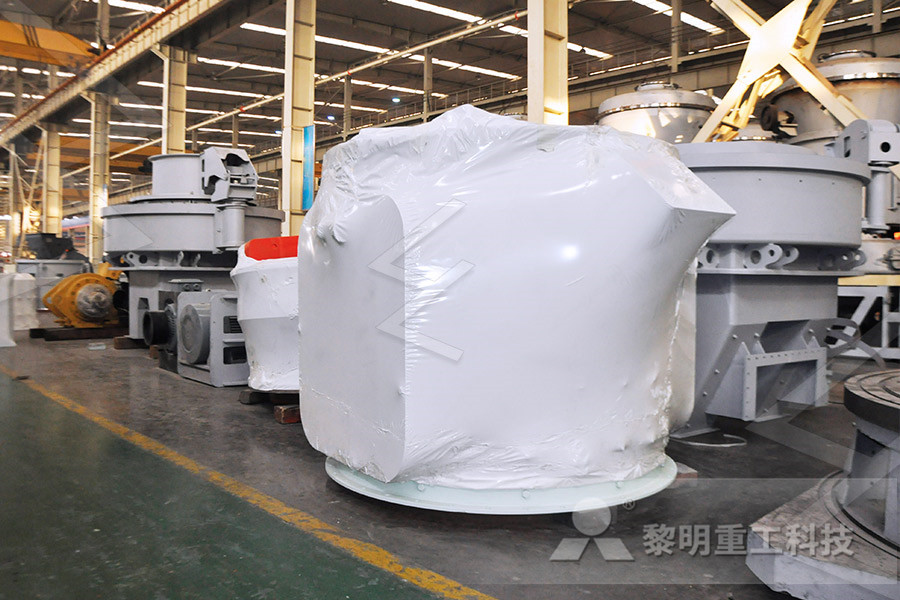

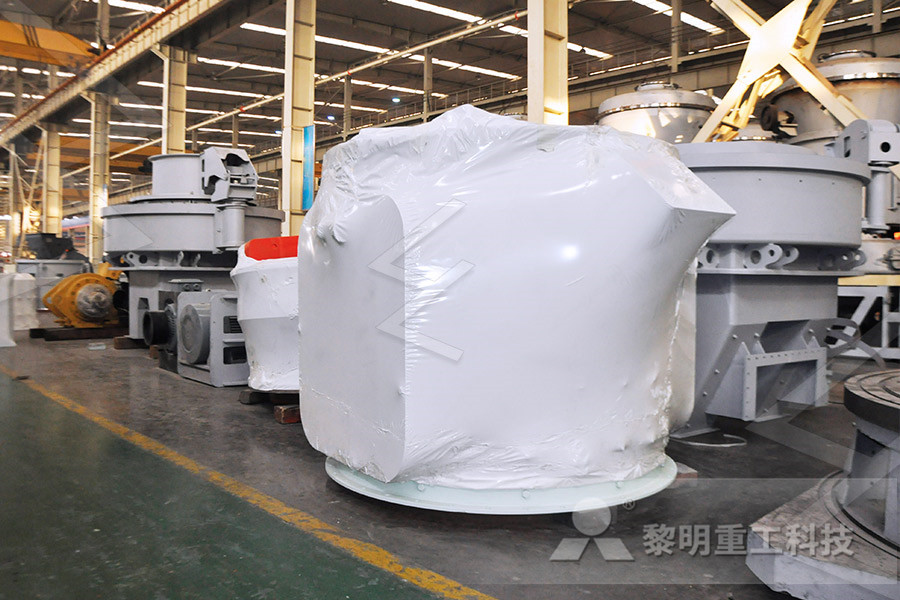

Mine Mill Equipment Cost Guide Costmine

Establishing baseline prices for appraisals The Mine Mill Equipment Cost Guide covers more than 3,000 items of mobile, portable, and stationary equipment commonly required by mining and milling operations Select from a 05/04/2017 ore is $234 The cost of transporting ore from the mine to the mill on contract is $1 per ton The milling cost of runofmine ore is taken as $285 and the cost of milling the sorted product is $322 per ton The mill recovery on the unsorted ore is estimated at 80 percent, and the recovery on the sorted ore is 87 percentCost of Stoping for Underground Mining16/01/2017 The plant throughput is how much ore (the raw rock) is mined and processed to extract the gold This is where the “grade” calculation from above is used In the Kalana Mine feasibility study Here's how you value any gold project

COSTS AND COST ESTIMATION Chapter NUBE MINERA

costs and operating costs depends on the quality of the technical assessment and knowledge of expected mining and mineral pro cessing conditions 6311 Cost Estimation for Preliminary Feasibility Studies Estimation of capital and operating costs of a proposed min ing venture is usually required after ore reserves have been deterFind the right mine mill from Alibaba Explore our mining equipment to find the ideal wholesale gold milling machine model and mills for any mining challengeSimple Ore Extraction: Choose A Wholesale gold milling 07/09/2017 Gold/silver base metal concentrate deportment Smelters typically pay >95% (Au) and 90% (Ag) in copper and lead concentrates, but will only pay 6070% (maximum, depending on degree of Pb/Zn smelter integration) for gold and silver in zinc concentrates Cost drivers are also important in flowsheet selection, and are summarised in Table 3Gold processing 101 Mining Magazine

Australia’s gold mines by production, grades and costs

22/05/2019 Scale, grades, processing costs, open pit vs underground The interesting aspect of the AISC metric is the number of factors that feed into the final figure, and similar to any other sector costs, they can vary from month to month and year to year In the case of gold stocks, better grades usually translate into lower cost minesMining Cost Service is the industry standard reference for Mining Cost Estimation This system places cost estimating data at your fingertips with conveniently indexed information to make your cost estimates faster, easier, and more credible Monthly updates assure that you are working with the most current cost data availableMining Cost Service CostmineGold extraction refers to the processes required to extract gold from its oresThis may require a combination of comminution, mineral processing, hydrometallurgical, and pyrometallurgical processes to be performed on the ore Gold mining from alluvium ores was once achieved by techniques associated with placer mining such as simple gold panning and sluicing, resulting Gold extraction Wikipedia

cost gold digging mills fourcinqau

cost gold digging millsOperating Costs of Gold Processing PlantMar 18, 2016The EXAMPLE Gold Mill is designed to process 500 tonnes per day of ore The flowsheets are conventional and consist of two stages of crushingEstablishing baseline prices for appraisals The Mine Mill Equipment Cost Guide covers more than 3,000 items of mobile, portable, and stationary equipment commonly required by mining and milling operations Select from a Mine Mill Equipment Cost Guide CostmineOperational cost for the first 3 months (salaries of employees, payments of bills et al) – $150,000 The cost for startup inventory (gold and silver ore mining equipment, trucks and other related gold and silver mining devices) – $250,000 The cost of launching a website – $600 Miscellaneous – $5,000Gold Mining Business Plan [Sample Template for 2022]

Simple Ore Extraction: Choose A Wholesale gold milling

Find the right mine mill from Alibaba Explore our mining equipment to find the ideal wholesale gold milling machine model and mills for any mining challenge23/03/2021 Gold miners are facing a reserves crisis, and what is left in the ground is becoming more and more challenging to processRefractory gold reserves, which require more sophisticated treatment methods in order to achieve oxideore recovery rates, correspond to 24 percent of current gold reserves and 22 percent of gold resources worldwide (Exhibit 1)Refractory gold reserves: Challenges and opportunities for 03/03/2022 Aris Gold CEO Neil Woodyer commented: "During 2021, we started construction of the Lower Mine project to transform Marmato into a longlife, lowcost operation capable of producing 175 koz of gold ARIS GOLD ANNOUNCES 2021 FINANCIAL AND OPERATING

gold processing Mining and concentrating Britannica

The nature of the ore deposit determines the mining and mineral processing techniques applied Oxide ore deposits are frequently of such low grade (eg, 3 to 10 parts per million) that extensive mineral processing cannot economically be justified In this case they are merely shattered by explosives and then piled into heaps for extraction by cyanidation (see below)Gold mining is the extraction of gold resources by miningHistorically, mining gold from alluvial deposits used manual separation processes, such as gold panningHowever, with the expansion of gold mining to ores that are not on the surface, has led to more complex extraction processes such as pit mining and gold cyanidationIn the 20th and 21st centuries, most volume of mining Gold mining Wikipedia01/01/2005 For the vast majority of ounces of gold produced, comminution costs in the form of power, grinding media, and liners represent the single largest cost category of milling Since, semiautogenous grinding (SAG) ballmill circuits represent the single largest type of gold milling comminution circuits, the chapter focuses on SAG At mines, where ore has become more Comminution circuits for gold ore processing ScienceDirect