magnetite beneficiation principle grinding roll for al

2021-12-13T02:12:19+00:00

Magnetite Beneficiation Mining and Mineral Processing

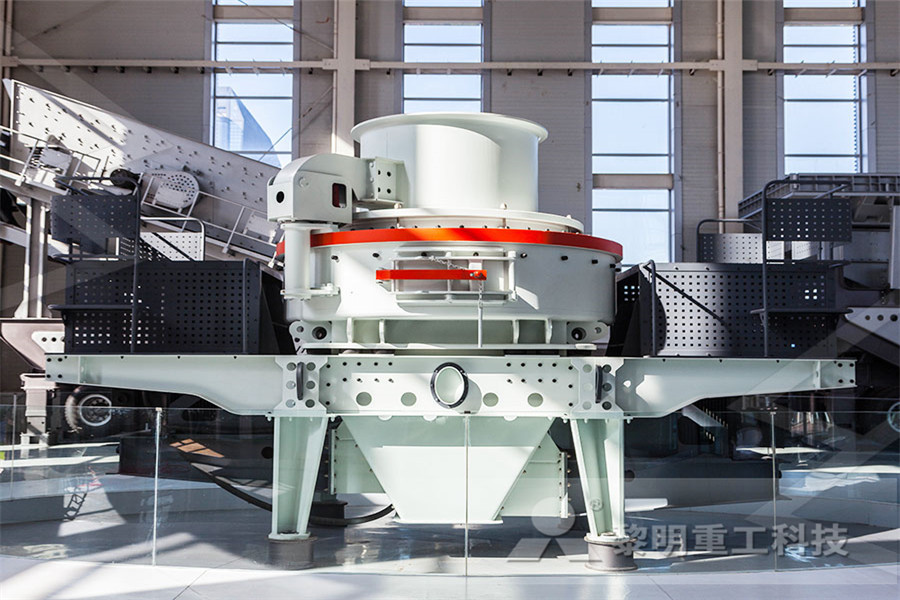

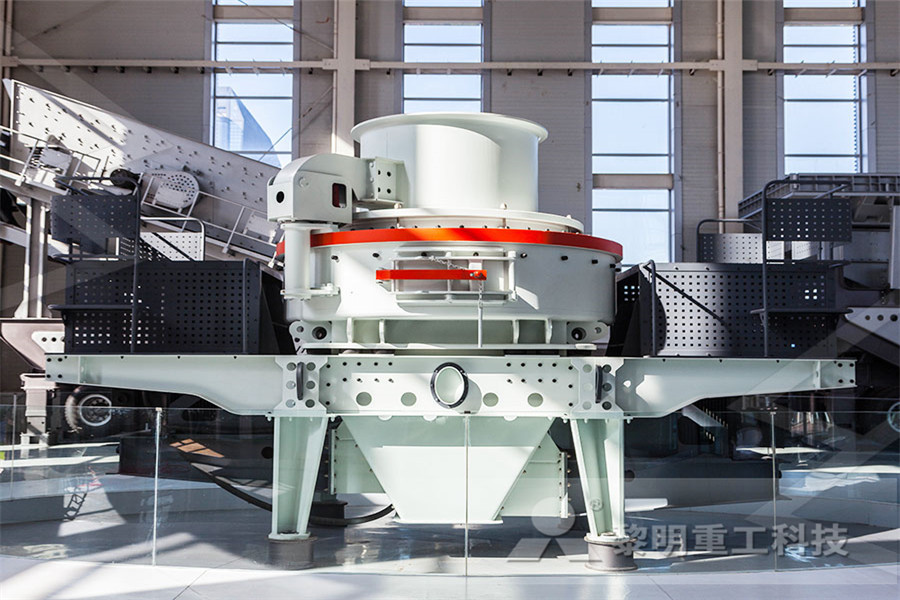

Magnetite Beneficiation or ore dressing production line combined by vibrating feeder, jaw crusher, vibrating screen, ball mill, classifier, magnetic separator, thickener and dryer and other main equipment With the feeder, hoist, conveyor can form a complete ore dressing production lineThe Magnetite Beneficiation production line has the Magnetite occupies a large proportion of China’s iron mineral reserves, reaching 488% Finding a reasonable magnetite beneficiation technology and machinery to deal with magnetite is of great significance for the development of our country’s mines and the development of the entire steel industryBrief Introduction of Magnetite Beneficiation Process and Compared to direct ship haemetite ores mined from the upper regolith, magnetite deposits require significant beneficiation, which typically (PDF) Processing of Magnetite Iron

Production process of lean magnetite ore beneficiation

on Production process of lean magnetite ore beneficiation The lean magnetite ore in Anshan area is a lean magnetite ore with high silicon and low sulfur and phosphorus The content of red and limonite is low, and the content of iron silicate and iron carbonate is relatively high At this time, many largegrained gangues can reach the monomer Magnetite Beneficiation Processing Fundamentals 1Day Training Course: A Technical Introduction for Investors Industry Newcomers Learn about the properties of magnetite, its processing requirements, what makes it a saleable iron ore that’s of market quality meets customer requirements Register Your Interest Call me backMagnetite Beneficiation Processing Fundamentals A typical study of the liberation of the magnetite was carried out by Xiao et al using a magnetite rougher concentrate in a stirred mill and a tumbling mill The research results suggested that the type of mill significantly affects the liberation of A study of the grinding of magnetite/limestone mixture in

(PDF) Beneficiation of beach magnetite sand

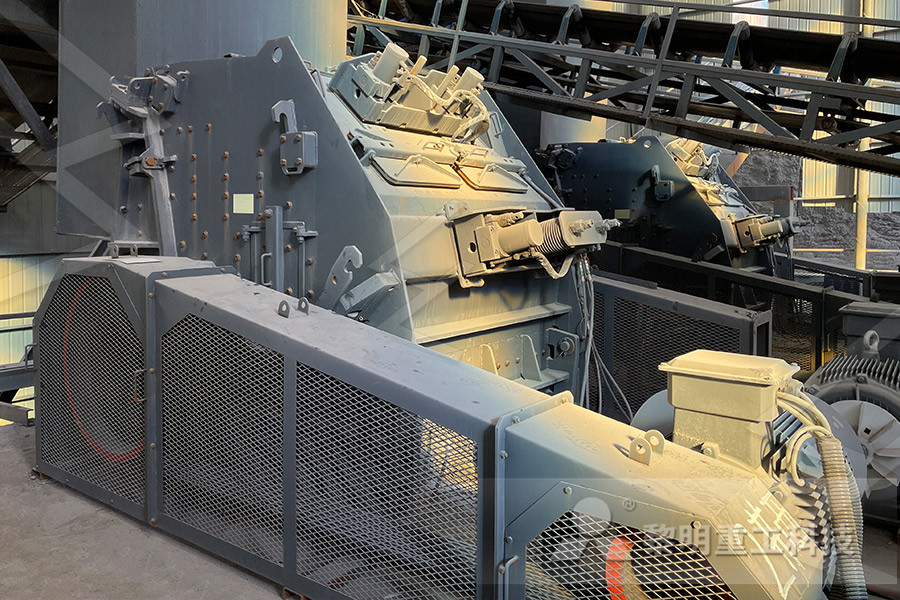

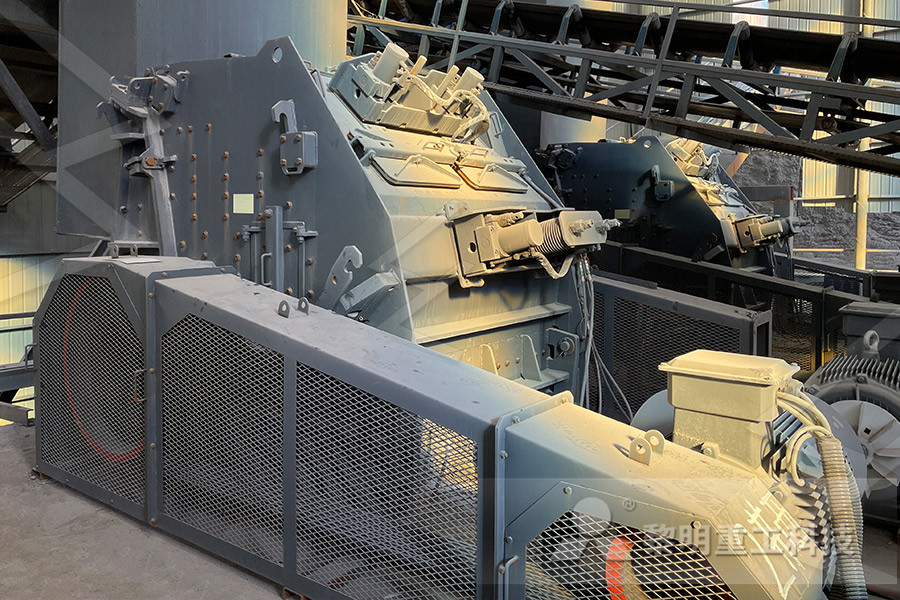

In this study, beneficiation of beach magnetite sand was investigated by applying high int ensity dry magnetic sepa rator The effect of feed particle size, feed rate, roll rotation speed Magnetite was removed from preconcentrate by using a wet low gradient magnetic separator Two serially connected magnetic separators were used at (PDF) BENEFICIATION OF MAGNETITE RICH That magnetite preselection with discarding tailings can effectively improve the grinding ore grade, which reduces the production costs, so we designed a kind of new magnetic rollerResearch on new magnetic roller for magnetite

Beneficiation an overview ScienceDirect Topics

11531 Beneficiation Mineral beneficiation begins with crushing and grinding of mined ore for nearcomplete separation of ore and gangue minerals as well as between ore minerals Each processing step is designed to increase the grade (concentration) of the valuable components of the original ore Magnetite Grinding In Laboratory Ball Mill grinding media its effect on pulp chemistry and magotteaux number of laboratory and plant case studies are used to illustrate the benefits of minerals such as pyrrhotite and magnetite particularly for forged steel grinding calibrate the magotteaux mill using sag mill feed read moremagnetite beneficiation principle grinding roll for almagnetite beneficiation principle grinding roll for al; magnetite beneficiation principle grinding roll for al High Tension SeparatorHaiwang Technology Group The electric separator drum diameter is 320 mm drum with electric heating device the land was shaped arc electrodesmagnetite beneficiation principle grinding roll for al

magnetite beneficiation principle wstvooruitgangnl

magnetite beneficiation principle grinding roll for al magnetite beneficiation principle grinding roll for al; chromite ore magnetic separator magnetite beneficiation Magnetic Separation and Iron Ore Beneficiation Magnetic separation is an old technique for the concentration of iron ores and for the removal of tramp ironHigh pressure grinding rolls at Whyalla magnetite Get Price; Magnetite Iron Ore Separation Of Iron Pyrite Wet Drum Magnetic Separator for Iron ore benefication Working principle of magnetite iron ore beneficiation plant The extracted ore should be tin, gulchgold Get Price; Magnetite Beneficiation 200 TphMagnetite Beneficiation Principle ulangMagnetite Beneficiation or ore dressing production line combined by vibrating feeder, jaw crusher, vibrating screen, ball mill, classifier, magnetic separator, thickener and dryer and other main equipment With the feeder, hoist, conveyor can form a complete ore dressing production lineThe Magnetite Beneficiation production line has the Magnetite Beneficiation Mining and Mineral Processing

Trends In Magnetite Ore Processing Testwork Rev0

magnetite ores in Western Australia (WA), using beneficiation to produce shippable magnetite concentrates These magnetite resources require higher cost processing techniques such as fine grinding and beneficiation to produce saleable concentrates This distinct difference, from the DSO ores, has lead to the development of a numberMagnetite Beneficiation Crushers, Ball Mills, Flotation Magnetite Beneficiation flow chart classificationThe spiral classifier uses the principle that the specific gravity of solid particles is different and the rate of precipitation is different in the liquid to clean and classify the ore mixtureAfter cleaning and classification of mineral mixture in the magnetic separator, due magnetite beneficiation principle Compared to direct ship haemetite ores mined from the upper regolith, magnetite deposits require significant beneficiation, which typically involves grinding to a particle size where magnetite (PDF) Processing of Magnetite Iron

magnetite for wet grinding XPEDIA

Your grinder has no flood coolant, and you prefer not to use some kind of spray mist coolant; you are going to be dry grinding the steel This is a typical injection mold making scenario, one that can be very frustrating It is possible to dry grind large workpieces on a manual surface grinder, but it is not easyProcessing of Magnetite Iron Ores – Comparing Grinding Options B McNab1, A Jankovic2, D David3 and P Payne4 ABSTRACT Although the majority of current steel production is Processing of Magnetite Iron Ores – Comparing magnetite ores in Western Australia (WA), using beneficiation to produce shippable magnetite concentrates These magnetite resources require higher cost processing techniques such as fine grinding and beneficiation to produce saleable concentrates This distinct difference, from the DSO ores, has lead to the development of a numberTrends In Magnetite Ore Processing Testwork Rev0

Magnetite Fine Beneficiation Plants BAS®

Magnetite Fine Beneficiation Plants BAS micronized magnetite ore beneficiation plants are either delivered on turnkey basis which process inlet ore to final micronized product or by facilitating prebeneficiation plants’ intermediarymaterial to achieve micronized end product through the following processes; Category Mining Beneficiation PlantsMagnetite was removed from preconcentrate by using a wet low gradient magnetic separator Two serially connected magnetic separators were used at this process which has 01 T and 02 T magnetic (PDF) BENEFICIATION OF MAGNETITE RICH magnetic separator for the size of 3mm below the magnetite, pyrrhotite, roasting ore, ilmenite and other materials, wet magnetic separation, but also for coal, nonmetallic minerals, building materials and other materials in addition to iron operations The magnetic system of the magnetic separator is made of high quality ferrite material or compound with rare earth Magnetic Separator himiningmachines

Magnetite Beneficiation Plant at Rs

Working principle of magnetite iron ore beneficiation plant The extracted ore should be crushed by jaw crusher initially When it gets the reasonable fineness, it is transported into ball mill by elevating conveyer and feeder, and is milled by The mineral composition and content are shown in Table 1According to the measurement result by MLA, the minerals in the ore were mainly magnetite and quartz, accounting for 3248% and 6173%, respectively, and their weight was accounted for 9421% of the total, indicating that the magnetite ores can be basically considered a twophase mineral The Effect of Grinding Media on Mineral Breakage Beneficiation of Iron Ores Iron ore is a mineral which is used after extraction and processing for the production of iron and steel The main ores of iron usually contain Fe2O3 (70 % iron, hematite) or Fe3O4 (72 % iron Beneficiation of Iron Ores IspatGuru

THE ENERGY SAVING TECHNOLOGY OF BENEFICIATION

216 VV KARMAZINet al still unliberated intergrown particles circulate from one stage to another, reducingtheefficiency ofthe process In the meantime, it follows fromTable 1, that the concentrates of stages II and III of magnetic separation, even with coarse grinding less than 0045mm, up to 2676% and 5010%, respectively already 33 Beneficiation Studies 331 Design of Flowsheet As shown in Table 3, the sample contains high contents of magnetite and biotite Magnetite is a ferromagnetic Table 1 The REE contents in the sample La ppm Ce ppm Pr ppm Nd ppm Sm ppm Eu ppm Gd ppm Tb ppm Dy ppm 859 2060 261 990 140 7 110 12 52 Ho ppm Er ppm Tm ppm Yb ppm Lu ppm Y ppm Mineralogy and Beneficiation of Lamujärvi Syenites in operating costs arise from reduced mass to the grinding circuit and the downstream beneficiation process Often, the preconcentrated minerals are of lower hardness than the gangue minerals hence the grinding circuit also benefits from lower energy requirements for equivalent feed mass and significantly reduced wear and media consumptionDense Media Separation – a Valuable Process for