pdf uses of jaw crusher r

2022-01-31T20:01:02+00:00

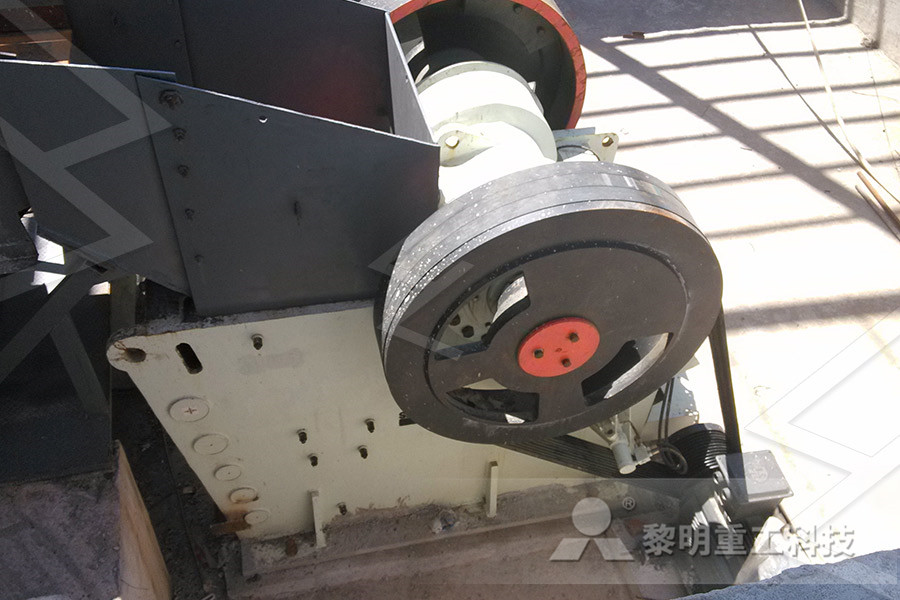

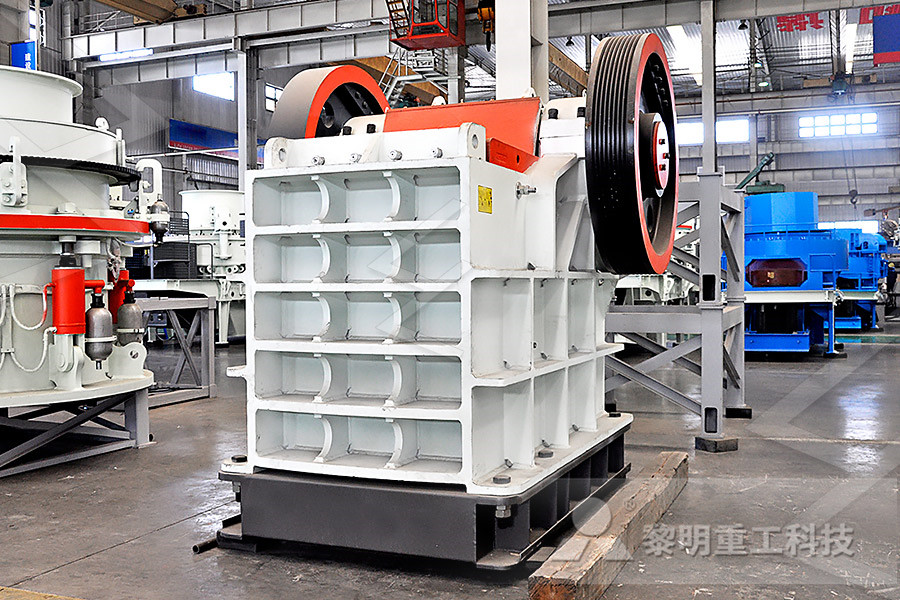

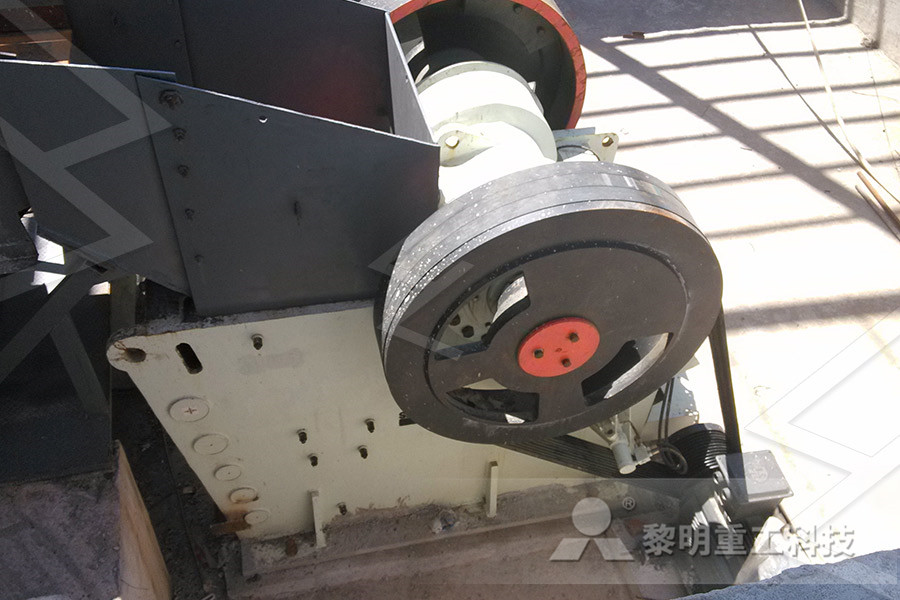

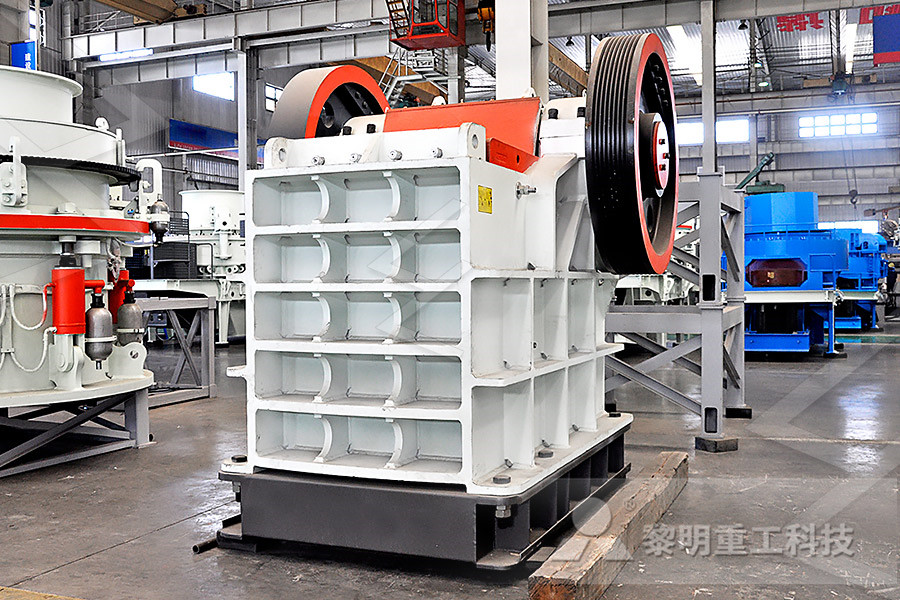

Operating Instruction JAW CRUSHER

Jaw crusher is mainly used for the medium granularity crushing of all kinds of ores and large materials in mine, metallurgy, building Jaw crusher is a crushing machine that is researched and developed very early With simple and solid structure, reliable work, easy maintenance and repair and low production and construction fees, it has long been vibrating feeder, jaw crusher, impact crusher or cone crusher, vibrating screen, belt conveyor and centrally electric controlling system, etc The designed capacity is from 40t/h to 600t/h To meet customer’s specific requirement for the stone crushing, we can also add other equipments such as cone crusher, dust catcher on the crushing plant Process of Crushing Plant The Big Crushing PlantJaw Crusher crusherThey are used in mines and quarries as primary crushers to crush blasted rockpile, which may have edge lengths of over 2,000 mm depending on the blasting method, in preparation for finish crushing or conveyingIndustrial Solutions Jaw crushers ThyssenKrupp

C Series jaw crushers

the heart and only purpose of the jaw crusher That is why over the years great attention has been paid to the feed opening dimensions as well as to the cavity height The right feed opening width to depth ratio ensures minimum blockage and eliminates unnecessary height from the crusher Aggressive kinematics and high powerAlthough jaw crushers are extensively used for a variety of materials, their operational characteristics are not well understood This lack of understanding makes selection of the proper machine difficult Hersam (1923) proposed a method for calculating capacities using a Dodgetype jaw crusher The equation proposed by Hersam includes aCapacities and performance characteristics of jaw crushersJaw Crusher Jaw crushers are mainly used as primary crushers to produce material that can be transported by belt conveyors to the next crushing stages From: Iron Ore, 2015 Download as PDF About this page Jaw Crusher In Mineral Processing Design and Operations (Second Edition), 2016 44 Jaw Crusher Capacity EstimationJaw Crusher an overview ScienceDirect Topics

pdf uses of jaw crusher andreasbernoit

pdf uses of jaw crusher JAW CRUSHER THE FIELDS OF APPLICATION Jaw crushers are used for primary crushing of a wide variety of materials in the mining, iron and steel and pit and quarry Development of hardfaced crusher jaws using ferro to low carbon steel substrate by manual metal arcwelding Usually, the austenitic manganese steel used in making crusher The prim arily used equipment in crushing arejaw crushers, gy rator y crushers and cone crushers whereas rod m ills and ball mills, closed circuited with a (PDF) SIZE REDUCTION BY CRUSHING METHODSAlthough jaw crushers are extensively used for a variety of materials, their operational characteristics are not well understood This lack of understanding makes selection of the proper machine difficult Hersam (1923) proposed a method for calculating capacities using a Dodgetype jaw crusher The equation proposed by Hersam includes aCapacities and performance characteristics of jaw crushers

Jaw Crusher Cheek Plate Liner Design

The jaw crusher is a compression type crusher Feed material is crushed between fixed and movable jaw dies Large particles are crushed in a single layer, referred to as singlelayer crushing Smaller particles are crushed rock on rock, referred to as multilayer crushing Feed opening Feed opening (depth of the cavity) defines the maximum feed size of the crusher In QJ241 JAW CRUSHER KEY SPECIFICATIONS DATA Equipment Single toggle C10 jaw crusher Feed opening 1000 mm x 650 mm / 40” x 26” Optimum feed size 520 mm3 / 21 inch3 Engine C71 Acert 168 kW / 225 hp Transport dimensions 1390 m / 45’ 7 ⅜” (l) 264 m / 8’ 7 ⅞” (w) 322 m / 10’ 6 ⅝” (h) Weight 32,568 kg / 71,800 lbs HIGH MOBILITY The QJ241 is the TECHNICAL SPECIFICATIONS QJ241 JAW CRUSHERJW42 (30” x 42”) Jaw Crusher, 42” x 20’ Feeder 150 hp (110 kW) 155 – 480 (140435) 3 Axle 92,625 lbs (42,015 Kg) CRJ3255 JW55 (32” x 55”) Jaw Crusher, 52” x 20’ / 24’ Feeder 200 hp (150 kW) 255 – 760 (231 690) 4 Axle 135,585 lbs (61,500 Kg) Portable mps mpsmarketing@ Product specifications and prices are subject to change without Jaw Crushers JW Series

pdf uses of jaw crusher sciekowekratkipl

pdf uses of jaw crusher; Jaw crushers thyssenkrupp Industrial Solutions They are used in mines and quarries as thyssenkrupp jaw crushers are mainly designed to crush Doubletoggle jaw crusher in use in a crushing plant TECHNICAL BRIEFING PAPER No 6 Institute of Quarrying Australia Jaw crushers are probably the most easily recognised crushers in any pdf uses of jaw crusher JAW CRUSHER THE FIELDS OF APPLICATION Jaw crushers are used for primary crushing of a wide variety of materials in the mining, iron and steel and pit and quarry Development of hardfaced crusher jaws using ferro to low carbon steel substrate by manual metal arcwelding Usually, the austenitic manganese steel used in making crusher pdf uses of jaw crusher andreasbernoitJaw crusher pdf files uses of stone crusher equipment pdf file stone crusher plant cost india uses of stone crusher equipment pdf file stone crusher used mobile stone crusher in india cost pdf by your pe jaw more details china crushing machine crushing machine manufacturers Online Chat Reliable TltAs Double toggle jaw crusher, type 2121, size Pdf Uses Of Jaw Crusher

Design of impact stone crusher machine CiteFactor

used crushers are basically of three types; namely, Cone crusher, Jaw crusher, and Impact Crusher The main objective is to design impact stone crusher Impact stone crusher involves the use of impact rather than pressure to crush materials The material is held within a cage, with openings of the desired size at the bottom, end or at sides to allow crushed material to escape Series jaw crushers easy to install The crusher can be installed as one compact module that includes all the necessary auxiliaries around the crusher itself The crusher can be installed within a few days, minimizing onsite engineering and fabrication Ultimately, this leads to a significant savings in time and installation costs Wide range of options C Series jaw crushers Crushing and screening solutions AggNetprocessing or to size suitable for the intended end use The goal of a crusher is to crush the given material in to the material with certain size and shape Information about crushing technology, construction, working and maintenance of crushers for bulk materials is given in this article Crushing Technology There are four basic ways to reduce size of a material: by Construction, Working and Maintenance of Crushers for

Jaw Crusher Cheek Plate Liner Design

The jaw crusher is a compression type crusher Feed material is crushed between fixed and movable jaw dies Large particles are crushed in a single layer, referred to as singlelayer crushing Smaller particles are crushed rock on rock, referred to as multilayer crushing Feed opening Feed opening (depth of the cavity) defines the maximum feed size of the crusher In Jaw die retention wedge retains the jaw die without the use of problematic key and heel plates Bearing Assembly Unique, efficient bearing assembly provides added strength and reliable longterm service Pioneer Jaw The Pioneer Series from KolbergPioneer, Inc represents the very latest in jaw crusher technology Engineered to be the highest capacity jaw crusher on the Crushing Astec IndustriesJaw Crusher Handbook Stone Crusher Pdf Jxsc Mine Jaw crusher equipment generally uses calciumbased grease Users can also use other types of grease according to the location of the machine, temperature and other conditions to choose But it must ensure the bearings with a good lubrication The Application Of Jaw Crusher In Different Industry Our crusher machine has Industrial Uses Of Jaw Crusher Pdf

Industrial Solutions Gyratory crushers ThyssenKrupp

Jaw gyratory crusher for underground iron ore mining and the crushing chamber of a BK 6375 in a stationary copper ore plant Jaw gyratory crusher with specially designed feed opening Fields of application • Coarse feed material • Block cave mining • Underground mining 6 Gyratory crushers 7 Crusher drives Customized crusher solutions crushers Industrial Solutions thyssenkrupp Primary crusherex jaw crusher, gyratory crusher Secondary breaking ex reduction gyratory crusher, cone crusher, disk crusher Fine crushing ex gravity stamp mill Following are the crushers under the scope of our syllabus Jaw crushers Gyratory crushers Cone crushers 251: Gyratory Crusher Gyratory crushers are the most efficient primary crushers for dealing with Design of a crushing system that improves the crushing A Jaw Crusher uses compressive force for breaking material This mechanical pressure is achieved by the crusher s two jaws dies one of which is stationary and the other is movable These two vertical manganese jaw dies create a Vshaped cavity called the crushing chamber where the top of the crushing chamber is larger than the bottom Jaw Crusher Handbook pdf uses of jaw crusher cadcamgmbheu

Crushing and screening solutions AggNet

Series jaw crushers easy to install The crusher can be installed as one compact module that includes all the necessary auxiliaries around the crusher itself The crusher can be installed within a few days, minimizing onsite engineering and fabrication Ultimately, this leads to a significant savings in time and installation costs Wide range of options C Series jaw crushers Safety Maintenance On Crushers spslSamplesslJawRockCrusherpdf custom developed training programs allow your organisation to invest in crushers pdf Home>Solutions > crushers pdf Department of Environmental Quality Environmental Assistance Program 18006629278 www ICE CRUSHER N°53 USER AND MAINTENANCE Jaw Crusher Maintenance Program Crushers Pdf Crusher Mills, Cone 01/01/2016 The size of a jaw crusher is usually described by the gape and the width, expressed as gape × width The common crusher types, sizes and their performance are summarised in Table 41Currently, the dimensions of the largest Blaketype jaw crusher in use are 1600 mm × 2514 mm with motor ratings of 250–300 kWJaw Crusher ScienceDirect

MOBILE PROCESSING Wirtgen Group

1st crushing stage, jaw crusher 2nd crushing stage, cone crusher Feed material 0550 mm, blasted Feed material 0160 mm, 1x precrushed Prescreen: Equipment of primary screening, see page 162, acc to chap “Setting up primary screening”, depending on Degree and size of impurities Type of impurities, eg sticky, cohesive (clay) or conveyable (wood, coal, humus)