mineral processing plant performance r

2022-03-27T10:03:05+00:00

How to Evaluate Mineral Processing Plant Performance

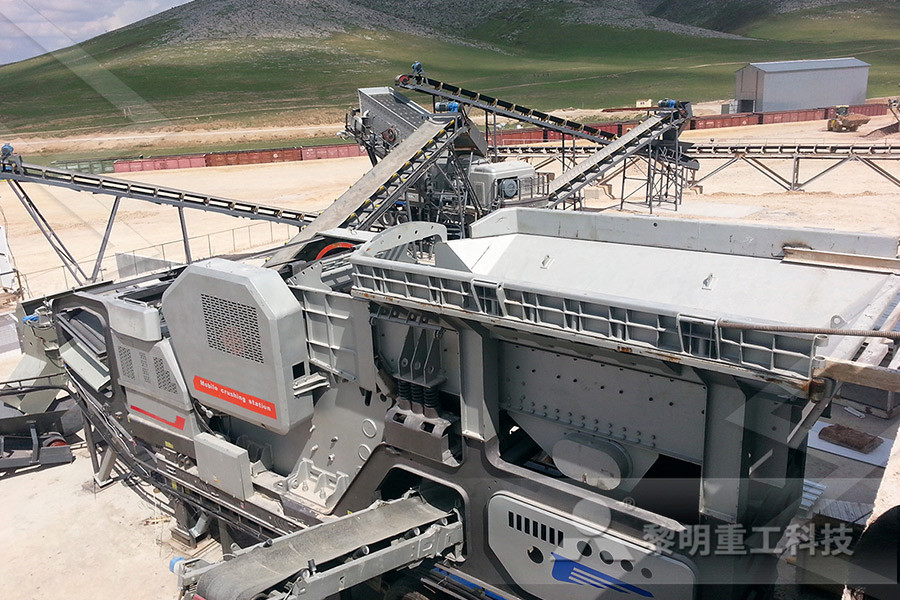

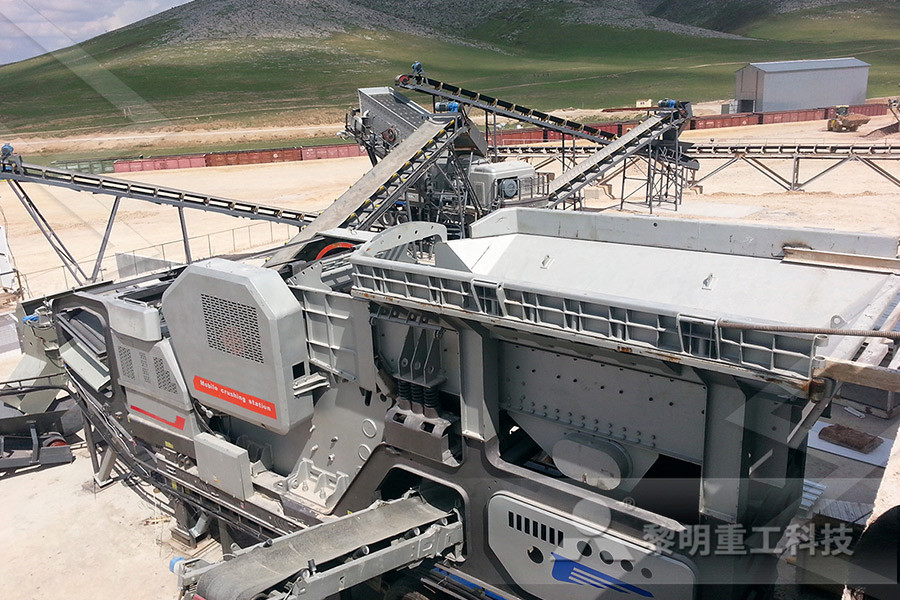

02/06/2016 Mineral Liberation; Gravity Concentration Testing; Flotation Testing; Hydrometallurgy Tests; Commissioning Training; Pilot Plant Design; Process Design Optimization; Processing Services; Free Metallurgical Help Blog; Archives; Foro de Metalurgista04/04/2018 Evaluate plant performance using CUSIM chart example by L D Michaud April 4, 2018 Categories Tools of a Metallurgist Post navigation PreviousEvaluate Mineral Processing Plant Performance Graphically 13/09/2021 Metallic Mineral Processing Plants New Source Performance Standards (NSPS) Basic Information Legal Authorities 42 USC §7411 The provisions of this subpart are applicable to the following affected facilities in metallic mineral processing plants: Each crusher and screen in openpit mines; each crusher, screen, bucket elevator, conveyor belt transfer Metallic Mineral Processing Plants New Source Performance

Mineral processing plant design and optimisation SlideShare

26/10/2012 Mineral processing plant design and optimisation to maximize throughput and keep product size within a limited range or to maximize downstream plant performance • The primary control objective • in any overall process control scheme is therefore that certain key physical variables (eg flows, concentrations, densities, levels, temperatures, pressures and In mining industry, it has been shown in [123] that there are statistically significant performance differences between the work shifts in control of the mineral processing plant The role of a Comparison of operator performance in a mineral processing Processing Plant Optimization Reduce costs and improve product quality by benchmarking and simulating process efficiency As a mine progresses through its life cycle, and as plant feed changes, the plant operation process should be continually reviewed and adjusted to maintain optimum performanceMine Processing Plant Optimization Extractive Metallurgy

Introduction to Mineral Processing or Beneficiation

12/01/2018 Comminution in the mineral processing plant is carried out in a sequential manner using The grizzlies can be vibrated to improve performance Figure 7 A grizzly Revolving Screen (Trommel) A trommel is a slightly inclined rotating cylindrical screen The material is fed at one end of the cylinder and the undersize material falls through the screening surface while An important aspect of any mineral processing study is an analysis of how material is distributed whenever streams split and combine This knowledge is necessary when a flow sheet is being designed and is also essential when making studies of operating plants In this lecture basics of material balance in mineral processing is discussedLecture 11: Material balance in mineral processing28/05/2015 TurnKey Processing Solutions doesn’t just build plants; we have a proven track record of operating them too Our operational expertise helps us understand your desired end result and guarantee optimal performance The process begins with collaboration We inspect your facility, interview managers and employees and listen to your objectives Our team works Mineral Processing Plant Optimization Operations Analysis

Capacity and performance profiles of process plant

economic study of capacity growth and performance change in operating plants Brennan drew on data from Australian plants in the chemical, mineral and petroleum processing industries However, it was following a secondment at ICI Australia, that led to his curiosity into how process plants like the earlier ethylene plants at Botany and many other Australian plants at that 13/09/2021 Metallic Mineral Processing Plants New Source Performance Standards (NSPS) Basic Information Legal Authorities 42 USC §7411 The provisions of this subpart are applicable to the following affected facilities in metallic mineral processing plants: Each crusher and screen in openpit mines; each crusher, screen, bucket elevator, conveyor belt transfer Metallic Mineral Processing Plants New Source Performance In mining industry, it has been shown in [123] that there are statistically significant performance differences between the work shifts in control of the mineral processing plant The role of a Comparison of operator performance in a mineral processing

A process performance monitoring methodology for mineral

The purpose of this study was to propose and evaluate a methodical approach to plantwide process performance monitoring for mineral processing plants Crucial to this approach is the concept of integrating process causality maps with databased systems for event detection and diagnosis To this end, process causality maps were developed to provide a means of Mineral processing consists of two functions Firstly, it involves the preparation and liberation, of the valuable minerals from waste minerals and secondly, the se paration these values into two (PDF) Overview of Mineral Processing Methods25/02/2021 Nonmetallic Mineral Processing: New Source Performance Standards (NSPS) Basic Information Legal Authorities 42 USC §7411; 42 USC §7414; Federal Register Citations 74 FR 19309; 73 FR 21559; 62 FR 31351; 61 FR 33415; 50 FR 31328; 48 FR 39566; Code of Federal Regulations Citations 40 CFR Part 60 Subpart OOO; Docket Numbers EPA Nonmetallic Mineral Processing: New Source Performance

Mineral Processing DECHEMA

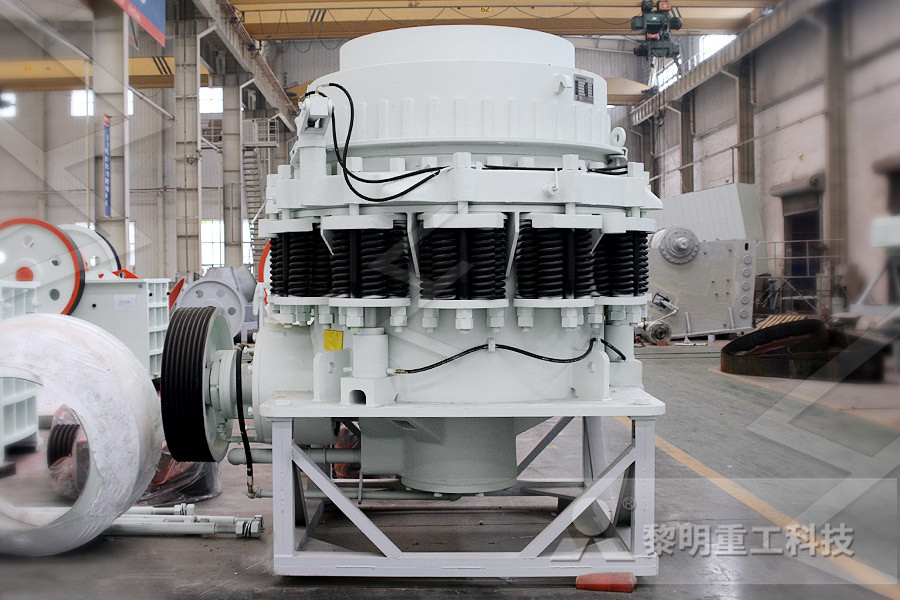

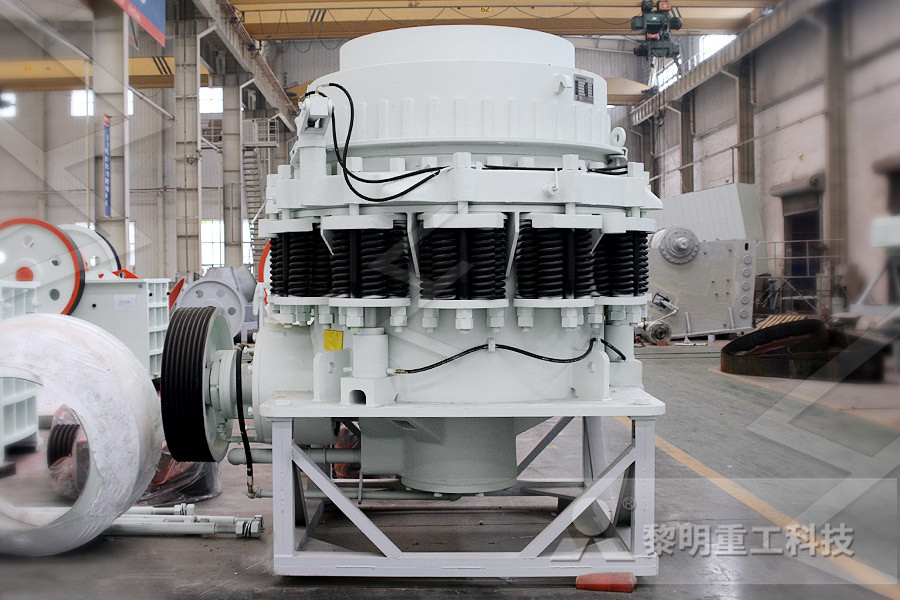

“Mineral processing is the first step in the solid mineral extractive process The goal is to produce granular material which meets a specific set of requirements in terms of material composition and physical characteristics (especially granulation) The minerals are then used either as is (eg potassium fertilizer, coal) or they pass through ad ditional processing stages Your Mineral Processing specialist Majola has over 20 years of experience in mining and extractive metallurgy He has held a wide range of positions in the mineral processing industry, including Production Metallurgist, Senior Plant Metallurgist and in sales Bheka has been with Multotec since 2013Mineral Processing Equipment MultotecPotash plant with high performance quipment efficiency and reliability are crucial at the K+S KALI GmbH Zielitz potash plant, one of Germany’s largest and most modern potash mining operations With an annual crude salt production of 12 million tonnes from a single shaft, the K+S KALI GmbH Zielitz operation is one of the most efficient potash Potash plant with high performance Mineral Processing

Hydrocyclone Multotec Multotec Mineral Processing

Engineered for maximum plant performance The Multotec hydrocyclone range comprises cyclone diameters from 25 to 1 400 mm Most of these diameters can accommodate a range of cone angles, while different vortex finders and spigot diameters are standard for all diameters The small diameter cyclones, up to 165 mm, are predominately polyurethane Processing Equipment Supplier Quarry Plant, Crusher and Screen,Crusher Parts Jaw Crusher, Crusher Wear Parts, Crusher Spare Parts HighPerformance Mineral Processing Equipment Supplier Welcome to Mackorn! As a specialized mining equipment manufacturer and supplier in China, we are devoted to the RD, fabrication and sales of heavy machinery Mackorn Machinery Co, Ltd HighPerformance Mineral High Performance Mineral Processing Plant Design Practice And Control Mineral processing operators use equipment to process mineral ores until the final form or a concentrate is produced Commonly processed minerals High Performance Mineral Processing Plant Design

Potash plant with high performance Mineral

Potash plant with high performance quipment efficiency and reliability are crucial at the K+S KALI GmbH Zielitz potash plant, one of Germany’s largest and most modern potash mining operations With an annual crude salt production Performance, environmental compatibility and economy at the highest level The brand new JAWMAX 200 ® offers highly professional crushing performance with optimal transport dimensions and a weight of less than 28 tonsMineral Processing Mineral Processing GmbH, an Austrian company with a longstanding tradition, ranks among the leading fullpackage suppliers of mineral processing plants and conveying plants for the natural stones and recycling industries and concrete mixing plants for readymixed and prefab concrete stands for more than 60 years of experience and is a globally wellestablished Mineral Processing GmbH, Austria Mineral processing

Basics in Minerals Processing Handbook Outotec

Basics in Minerals Processing Handbook gives practical information about the process equipment used, their systems and operational environment A classic Read by thousands of individuals interested in practical information of processing equipment and systems Menu Close Industries Mining Supporting your mining operations, from plant design expertise to Processing Equipment Supplier Quarry Plant, Crusher and Screen,Crusher Parts Jaw Crusher, Crusher Wear Parts, Crusher Spare Parts HighPerformance Mineral Processing Equipment Supplier Welcome to Mackorn! As a specialized mining equipment manufacturer and supplier in China, we are devoted to the RD, fabrication and sales of heavy machinery Mackorn Machinery Co, Ltd HighPerformance Mineral 01/01/2007 "Process engineers in mineralprocessing plants are generally not well trained in process control and, except in very large companies, there are usually no processcontrol engineers on the plant" This section addresses both of these points The XPS Process Control Group's philosophy is summarised as follows: Employ appropriate number of skilled PROCESS CONTROL IN METALLURGICAL PLANTS ScienceDirect

Home Page NIAflow

Single or multiple plants can be set simulated for reliable performance forecasts Pricing » Compare NIAflow Versions It gives all tools that you need to develop, characterise and optimise a mineral processing plant in a single software package The professional reporting and accurate mass balancing are some of the features that can assist in proper selection of Shandong Xinhai Mining Technology Equipment Inc, is a stockholding high and new technology enterprise to provide “Turnkey Solution for Mineral Processing Plant” including design and research, machine manufacturing, equipment procurement, management service, mine operation, mine materials procurement management as well as industry resources integrationoverdriveperformancedeOnestop service for mineral mines, mineral processing plants and metallurgical plants, the design team has to consider many operating parameters and design criteria Without computer tools that make metallurgical calculations simple and fast, this is almost impossible to do in a timely manner These tools can evaluate performance for a variety of process concepts, design criteria such as ore grades, Role of Simulation Software in Design and Operation of