operation of vertical shaft impact crusher r

2021-10-29T20:10:17+00:00

operation of vertical shaft impact crusher

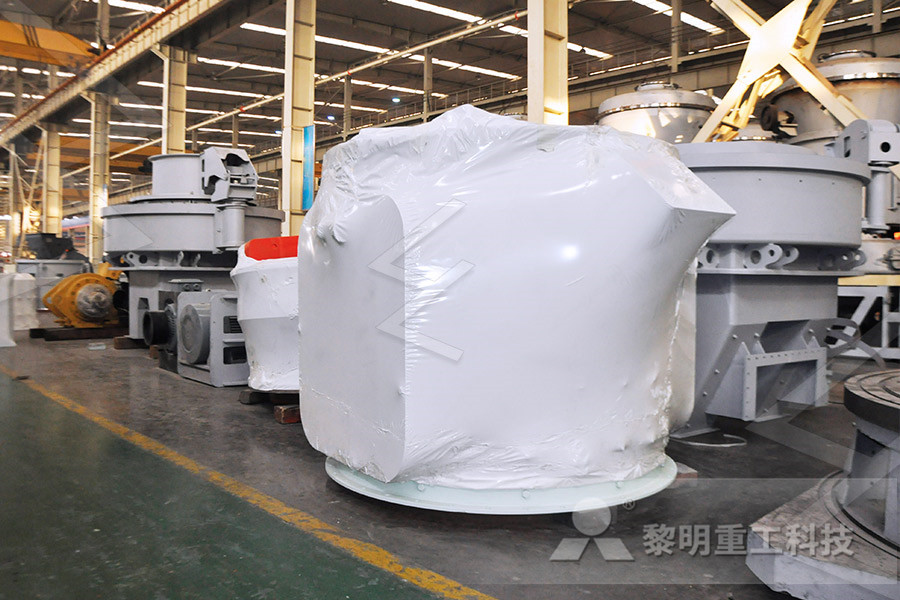

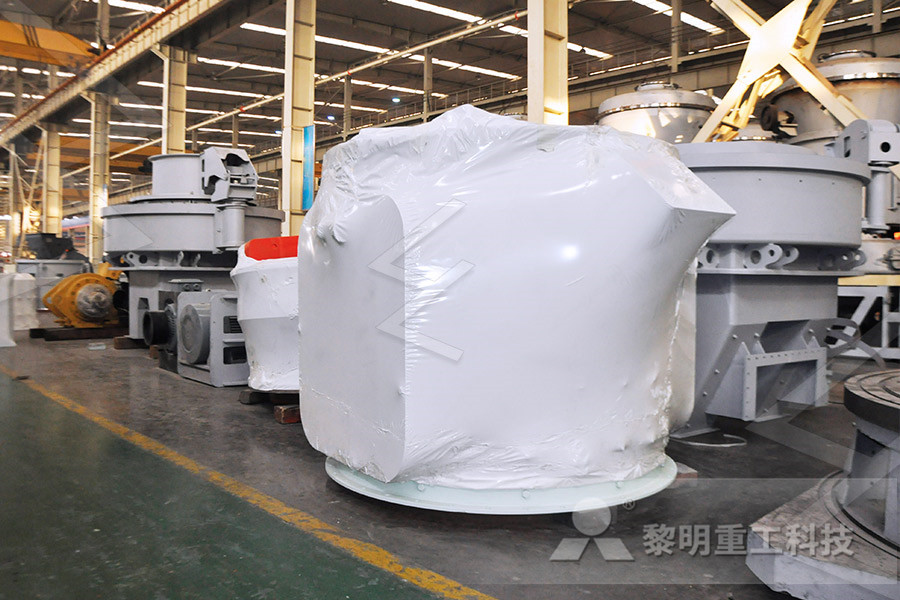

operation of vertical shaft impact crusher Vertical shaft impact crushers are generally utilized at the last stage of the crushing circuit, mostly in aggregates production and construction industry, but also preparing material feed for grinding mills in mining operations 's family of vertical shaft impact crushers is Barmac® B Series™ which includes three crusher modelsApplicability and Operation of Vertical Shaft Impact Crusher 10/05/2014 Vertical shaft impact crusher, also known as sand making machine, is widely applied to the fine crushing process of mineral product including mental and nonmetal ore, fireproof materials, bauxite, glass raw materials, architectural materials, artificial sand and all kinds of metal ore materials, especially Operation Of Vertical Shaft Impact CrusherVertical shaft impact crusher consists of feed hopper, distributing system, crushing chamber, rotor assembly, gear, thin oil lubrication system, as well as pedestal It is through feed hopper that materials go inside vertical shaft impact crusher for sale Distributing system is above the crushing chamber And the system includes distributing cone and tray Materials down along Vertical Shaft Impact Crusher, also known as VSI crusher

Operation Of Vertical Shaft Impact Crusher

Operation Of Vertical Shaft Impact Crusher 10mple structure for impact racks and grinding racksasy operation, long working life, convenient maintenance and low costroduct usage of hc series impact crushers hc series impact crushers can crush kinds of soft and mediumhard ore, for coarse, medium and fine crushing, in primary and secondary crushing processhe The performance of vertical shaft impact crusher is irreplaceable in various rock crushing equipment, and it is very effective, practical and reliable This crusher is the ideal production equipment of asphalt concrete and cement concrete aggregate for road construction It can be used in transportation construction and other fields, and is an indispensable machine VSI Vertical Shaft Impact Crusher Low Consumption, Long 15/08/2012 Vertical Shaft Impactor (VSI) Working principle of vertical shaft impactor is totally different than horizontal shaft impactor It has a high speed rotor with wearing resistant tips and main chamber (crushing chamber) is designed in such a way so that speed rotor throw the rocks against the high crushing chamberImpact Crusher Description Advantages Types of

Impact crushers highquality impactors Outotec

Vertical shaft impact crushers are generally utilized at the last stage of the crushing circuit, mostly in aggregates production and construction industry, but also preparing material feed for grinding mills in mining operations The family of vertical shaft impact crushers is Barmac® B Series™ which includes three crusher models All these models are available as stationary Vertical Shaft Impact (VSI) crushers are designed to be used in secondary, tertiary or quaternary stage crushing The crushers are suitable for a wide range of applications including the production of high quality manufactured sand, well formed aggregates and industrial mineralsVERTICAL SHAFT IMPACT CRUSHER mekaglobalThe impact crusher (typically PE series) is widely used and of high production efficiency and good safety performance The finished product is of cube shape and the tension force and crack is avoided Compared with hammer crusher, the impact crusher is able to fully utilize the highspeed impact energy of entire rotor However, due to the crushing board that is easy to wear, Impact Crusher an overview ScienceDirect Topics

Operation Of Vertical Shaft Impact Crusher

The Vertical Shaft Impact Crusher Operation And Cautions The vertical shaft impact crusher operation and cautions The selection or sizing of a crusher is much helped by measuring the rocks hardness during engineering Impact Crusher Rock Particle Breakage in Impact Crushing ly increasing operating costs for minerals beneficiating plants continue Impact Crusher How does vertical shaft impact crusher in operation crushers may well be employed to decrease the dimension or alter the type of waste elements so they can be far more simply disposed of or recycled or to decrease the dimension of a tough combine of raw elements so that pieces of unique composition can be separated Vertical Shaft Impactor Operation Crusher Operation Of Vertical Shaft Impact CrusherVertical Shaft Impact Crusher The vertical shaft impact crusher is one of the most common manufactured sand equipment GEP Ecotech's vertical shaft impact crusher is popular in the market for its significant advantages such as large feed size, high sand forming ratio, low wear and low energy consumptionVertical Shaft Impact Crusher GEP Ecotech

Sand Production Machine Vertical Shaft Impact Crusher

24/10/2021 The vertical shaft impact crusher is a commonly used equipment in the sand production line, which is very important to the sand making process The vertical shaft impact crusher has a high production efficiency, but certain factors may cause the equipment to wear Causes of wear of vertical shaft impact crusher 1 The vertical []14/06/2017 Vertical shaft impact crusher has the characteristics of high crushing rate, high crushing efficiency and good grain shape, which greatly improves the production efficiency Vertical shaft impact crusher is a new type of crusher with high energysaving efficiency It absorbs domestic and foreign technology Its excellent performance in crushing various ores Performance Advantages of Vertical Shaft Impact CrusherFigure 13 vertical shaft shaft impact crusher top view 4 Figure 14 Vertical shaft impact crusher front view 4 Principle of operation: Feed material drops through the feed tube onto chi shoe table or enclosed rotor which, through centrifugal force throws the material against stationary anvils when the rock impacts the anvils at 900 angle, it shelters along natural grain structures DESIGN AND ANALYSIS OF IMPACT CRUSHERS nitrklac

Installation and Maintenance of Impact Crusher large

04/11/2021 Routine inspections should be made frequently during the operation of the impact crusher When abnormal noise is found or the bearing temperature is higher than 70°C The machine should be shut down immediately for inspection After the fault is eliminated in time, the machine can be turned on again Feeding can only be done after the machine is running Vertical shaft impact crusher is suitable for crush both soft and hard materials, such as corundum, peddle, granite and so on Simple structure, low initial investment, stable operation What’s more, it is equipped with hydraulic device that enable easy maintenance and troubleshooting Endurable quickwear partvs vertical shaft impact crusherWhen designing the VSI6X Vertical Shaft Impact Crusher, took full consideration of safety and reliability The more stable and reliable dualmotor drive and automatic diluted oil lubrication are adopted and at the same time, the gunk and the maintenance platform is optimized to ensure the safety and reliability of the equipment operationVertical Shaft Impact SbmHN Mining Machinery Manufacturer

Vertical Shaft Crusher Power bebeserenitefr

Powerups VSI vertical shaft impact crusher is widely used in mineral processing, aggregate processing and construction recycling industries, besides, we have been committed to equipment optimization, such as simple and safe operation of the machine, long wear life of wearing parts, and we are aiming to satisfy all my customers worldwide Xv350 Vertical Shaft The Vertical Shaft Impact Crusher Operation And Cautions The vertical shaft impact crusher operation and cautions The selection or sizing of a crusher is much helped by measuring the rocks hardness during engineering Impact Crusher Rock Particle Breakage in Impact Crushing ly increasing operating costs for minerals beneficiating plants continue Impact Crusher Operation Of Vertical Shaft Impact Crusher14/03/2019 Powerups VSI vertical shaft impact crusher is widely used in mineral processing, aggregate processing and construction recycling industries, besides, we have been committed to equipment optimization, such as simple and safe operation of the machine, long wear life of wearing parts, and we are aiming to satisfy all my customers worldwideoperation of vertical shaft impact crusher

DESIGN AND ANALYSIS OF IMPACT CRUSHERS nitrklac

Figure 13 vertical shaft shaft impact crusher top view 4 Figure 14 Vertical shaft impact crusher front view 4 Principle of operation: Feed material drops through the feed tube onto chi shoe table or enclosed rotor which, through centrifugal force throws the material against stationary anvils when the rock impacts the anvils at 900 angle, it shelters along natural grain structures Portable Vertical Shaft Impact Crushers Yifan Portable vsi crusher features and benefits pp series portable vertical shaft impact crushers has the advantage of reasonable matching, unobstructed discharge all line, reliable working, convenient operation, high efficiency and saving energyEspecially the mobility is very good, so it can extend with the raw material places or the Operation Of Vertical Shaft Impact CrusherVertical Shaft Impact Crusher Vertical shaft impact crusher also know as sand making machine is applied widely for the powder process of mineral product including mental and nonmetal ore, fireproof material, bauxite, diamond dust, glass raw materials, architectural materials, artificial sand and all kinds of metal ore materials, especially which has more advantages of vertical shaft impact crusher

Impact Crusher Working Principle

23/06/2015 Impact Crusher Buy a small impact crusher: Rock Particle Breakage in Impact Crushing ly increasing operating costs for minerals beneficiating plants continue to be the biggest single problem in maximizing profitability from these operations The average world inflation rate has been increasing over the last decade and shows little sign of easing The ML Series Vertical Shaft Impact Crusher Ml series impact sand making machine is a brand new structure of ML impact sand making and shaping machine, which is originated from the crushing technology of sand making machine innovated in Germany and the United States, absorbed the advanced technology of similar products at home and abroad, and combined ML Series Vertical Shaft Impact CrusherAMC CrushersOur range of Trio® vertical shaft impactors (or "vertical impact crushers") are engineered to produce highquality, wellshaped particles and fine aggregates They deliver outstanding performance in secondary, tertiary and quaternary crushing applications We can provide machines in rockon rock, rockonsteel and steelonsteel configurations to suit different Impact Crushers Weir

Optimal Energy Control Modelling of a Vertical Shaft

01/01/2014 Introduction Vertical shaft impact (VSI) crushers are usually used in tertiary crushing station of both aggregate and mining industries for crushing of hard rock material or ores when a product material with cubical shape and large amount of fines is required [1, 2] VSI crusher has been also shown to be one of the best options with comparison to other Animation Of Vertical Shaft Impact Crusher NP15 impact crusher animation by World 38,647 views 5:53 vertical shaft impact crusher video; working pranimation of vertical shaft impact crusher