illustration on the processes of making a cement r

2022-06-23T12:06:29+00:00

illustration on the processes of making a cement

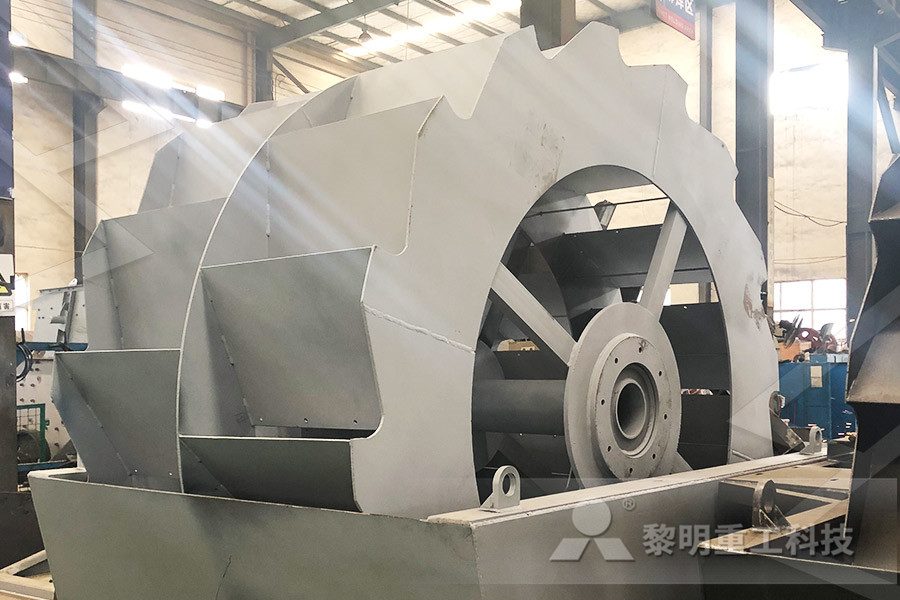

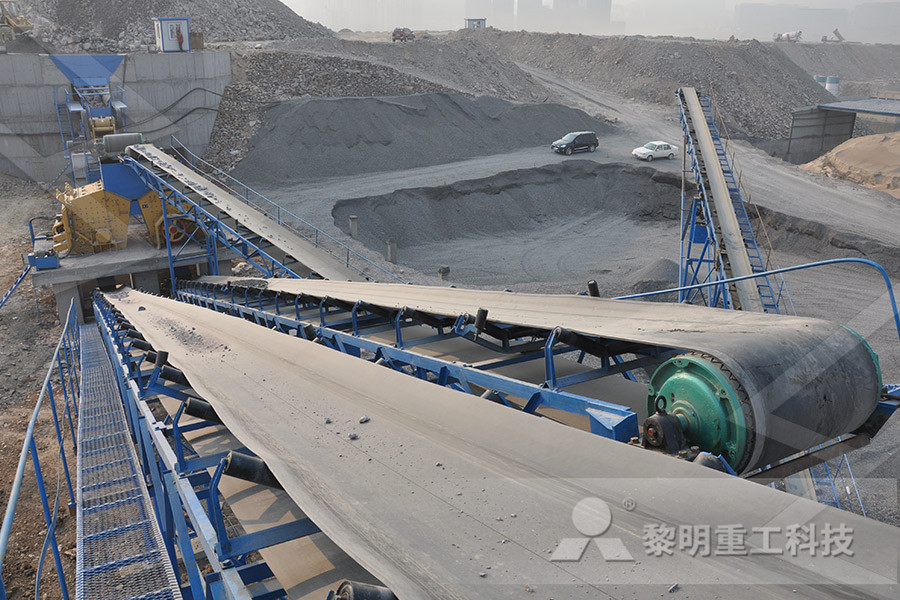

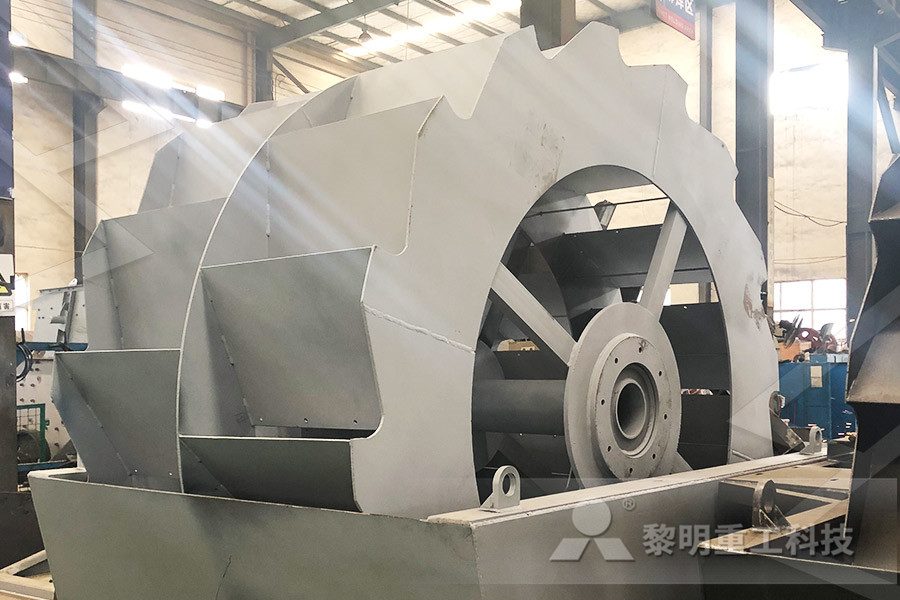

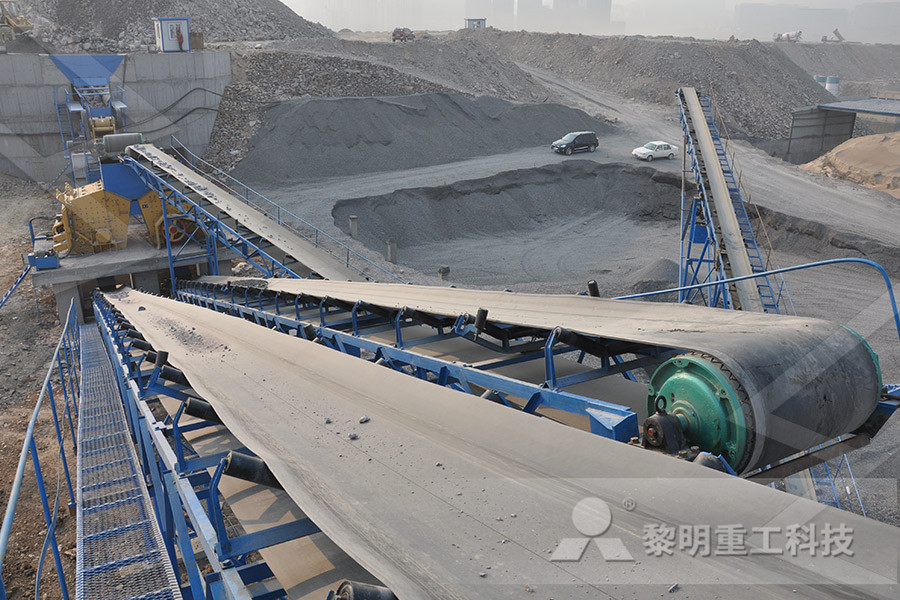

illustration on the processes of making a cement; How Concrete is Made Portland Cement Association How Concrete is Made In its simplest form, concrete is a mixture of paste and aggregates, or rocks The paste, composed of portland cement and water, coats the surface of the fine (small) and coarse (larger) aggregates Through a chemical reaction called hydration, HOME>illustration on the processes of making a cement illustration on the processes of making a cement How Cement Is Made Portland Cement Association Cement is so fine that 1 pound of cement contains 150 billion grains The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects Although the dry process illustration on the processes of making a cementThe diagrams illustrate the processes of making cement and concrete Overall, it can be seen that there are five stages in the cement production beginning with crushing limestone and clay and ending with packaging, meanwhile, the production of concrete has two stages In the first process, limestone and clay are put through the crusher and converted into power After that, The diagrams illustrate the processes of making cement and

Illustration of a typical cement manufacturing process

A few thermodynamic studies can be found evaluating the application of oxyfuel combustion to cement making Hokfors et al (2014) studied the effect Illustration On The Processes Of Making A Cement Aug 30 2012 cement manufacturing process phase iv kiln phase kiln is a huge rotating furnace also called as the heart of cement making process here raw material is heated up to 1450 ⁰c this temperature begins a chemical reaction so called decarbonation in this reaction material like limestone releases the carbon Illustration On The Processes Of Making A CementA few thermodynamic studies can be found evaluating the application of oxyfuel combustion to cement making Hokfors et al (2014) studied the effect of oxygen enrichment of the air, ie without Illustration of a typical cement manufacturing process

The diagrams illustrate the processes of making cement and

The diagrams illustrate the processes of making cement and concrete Overall, it can be seen that there are five stages in the cement production beginning with crushing limestone and clay and ending with packaging, meanwhile, the production of concrete has two stages In the first process, limestone and clay are put through the crusher and converted into power After that, The first illustration demonstrates how cement is being produced step by step while the second one shows us the production of concrete Both processes are man made Portland cement Wikipedia Portland cement is the most common type of cement in general use around the world as a basic ingredient of concrete These processes can vary widely Cement making skf cement processesillustration on the processes of making a cement CONCRETE BASICS A Guide to Concrete Practice Concrete Basicswill help to generate a higher standard of workmanship onsite and facilitate better communication among construction workers builders engineers building surveyors architects and anyone interested in understanding the processes involved in making quality illustration on the processes of making a cement

Cement Manufacturing Process Phases Flow Chart

30/08/2012 Kiln is a huge rotating furnace also called as the heart of cement making process Here, raw material is heated up to 1450 ⁰C This temperature begins a chemical reaction so called decarbonation In this reaction material (like limestone) releases the carbon dioxide High temperature of kiln makes slurry of the material Rotary kiln The series of chemical reactions Illustration On The Processes Of Making A Cement Aug 30 2012 cement manufacturing process phase iv kiln phase kiln is a huge rotating furnace also called as the heart of cement making process here raw material is heated up to 1450 ⁰c this temperature begins a chemical reaction so called decarbonation in this reaction material like limestone releases the carbon Illustration On The Processes Of Making A Cement14/03/2022 However, concrete needs cement for its preparation while gravel is 50 percent of the mixture, cement (15%), sand (25%) and water (10%) are used in less proportions both processes are similar, but the only difference is cement production is in dry form and concrete production is in wet formTask 1 (Process) : Cement making process IELTS Writing

Manufacturing of Cement By Dry and Wet Process Expert Civil

Cement Manufacturing Process Flow Chart (i) Drying Zones: In the wet process, the drying zone is comparatively larger than the dry process It is because the raw material in slurry form is directly fed into the kiln which has more amount of water As shown in 20/08/2015 The Cement Manufacturing Process flow chart sums up where in the process each type of technology is making a difference NOTE: Need a Belt scale system for your bulk material handling? To help you decide which belt scale system is best for your mining operation, we’ve outlined the options in an easytoread belt scale system selection guide so you can The Cement Manufacturing Process Advancing MiningOverall the cement making process involves several steps (crushing, mixing heating and grinding) to make cement from limestone and clay Whereas concrete making process just involves the mixing of various elements (cement, sand, gravel and water) in a proper portion to be mixed well to make concrete In cement production, limestone and clay are crushed together IELTS Process Diagram Examples IELTS buddy

cement processes

The first illustration demonstrates how cement is being produced step by step while the second one shows us the production of concrete Both processes are man made Portland cement Wikipedia Portland cement is the most common type of cement in general use around the world as a basic ingredient of concrete These processes can vary widely Cement making skf The two diagrams illustrate the cementmaking process We can see from the given illustration that cement is manufactured first, and then it’s used in the concrete production In the first diagram, we can see that limestone is the raw material with which clay added Firstly, the two materials are crushed to form the powder Then this powder passes through a mixer and a Task 1 ( Diagram) – Stages And Equipment Used In The The crushed raw ingredients are made ready for the cement making process in the kiln by combining them with additives and grinding them to ensure a fine homogenous mixture The composition of cement is proportioned here depending on the desired properties of the cement Generally, limestone is 80% and remaining 20% is the clay In the cement plant, the raw mix Cement Manufacturing Process Civil Engineering

Manufacturing of Cement By Dry and Wet Process Expert Civil

Cement Manufacturing Process Flow Chart (i) Drying Zones: In the wet process, the drying zone is comparatively larger than the dry process It is because the raw material in slurry form is directly fed into the kiln which has more amount of water As shown in Cement Production Cement Howden Playing a key role in the moving mixing heating and cooling processes Howden products are used throughout the cement production process Our blowers are used to move the iron ore calcium carbonate silica and alumina immediately after extraction and continue to be used throughout the process and once the end product is generated and processes of cement production30/10/2021 Process for making Cement paint The cement and the colorants are added in the ball mill through the charging manhole Once that is done the manholes are shut and the ball mill is allowed to rotate As the mill rotates the powders are uniformly blended to form a homogeneous powder Once the desired finish is attained the manholes are fitted Cement Making Process Machines manufacturer, supplier, and

How Cement Is Made Portland Cement Association

Cement is so fine that 1 pound of cement contains 150 billion grains The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process The two processes are processes of making cement in india with diagram This cement plant operates on a dry process line with a vestage suspension preheater and an inline precalciner the kiln is 4 m in diameter and 60 m in length If you want to learn about our products , please call or write mail consultation Send : [ protected] If you are interested in our products, please processes of making cement in india with diagramManufacturing of cement involves various raw materials and processes Each process is explained chemical reactions for manufacture of Portland Cement Cement is a greenish grey colored powder, made of calcined mixtures of clay and limestone When Calcium aluminate cements Wikipedia History The method of making cement from limestone and lowsilica processes of making cement in kazakhstan with diagram

exercises on the processes of cement

exercises on the processes of cement; Concrete Experiences and Practical Exercises The first step in the ELM is a concrete experiencedesigned in the affective learning domain When students are first presented with a new situation, the very first exposure is in the form of a concrete experience (CE) The concrete experience must be an active, interactive event that