Mineral Processing Minesite r

2022-10-21T17:10:00+00:00

Mineral Processing an overview ScienceDirect Topics

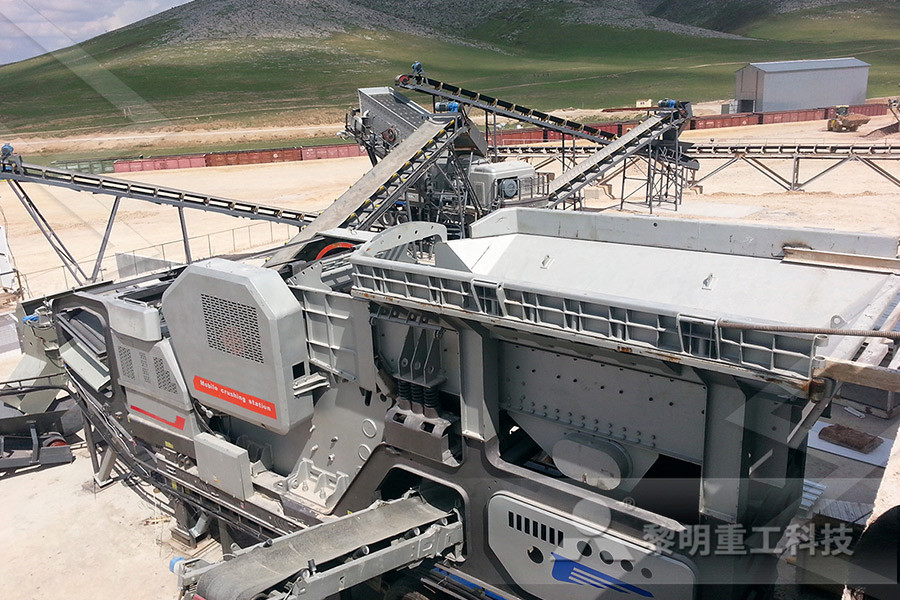

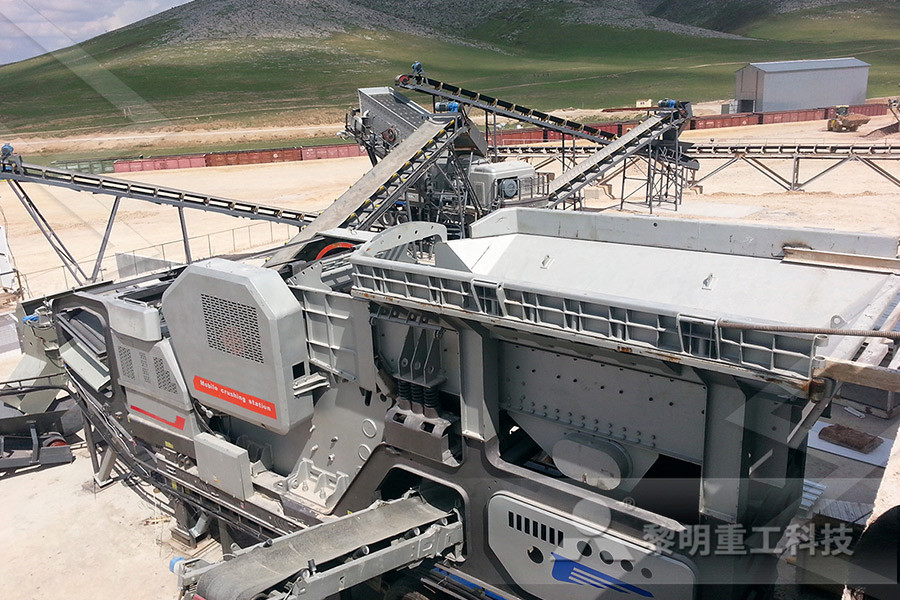

Mining and mineral processing generates large volumes of waste, including waste rock, mill tailings, and mineral refinery wastes The oxidation of sulfide minerals in the materials can result in the release of acidic water containing high concentrations of dissolved metals Recent studies have determined the mechanisms of abiotic sulfidemineral oxidation Within mine wastes, the mineral processing minesite mineral processing minesite Mineral Processing Laron Mineral processing covers the full gamut of crushing, transporting, rendering, enriching and refining the ore into product A wide range of skills are required for a truly full solution services provider to safely tear down and inspect damaged or worn equipment, access the best repair mineral processing minesite hotelrestaurantcorsefrThe first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing It is a process of ore preparation, milling, and ore dressing(PDF) Overview of Mineral Processing Methods

Why Mineral Processing is Very Important for the Mining

Mineral processing has many advantages for the mining industry These areas follow 1 making the mineral resource profitable for mining If the valuable minerals within the ore cannot be recovered separately from the gangue material, the resource is not an ore in the first placeMineral Processing Minesite Mineral exploration and mine development,public policies influencing mining, and mineral prices and production costs In addition, and not part of this paper, minesite exploration takes place at or in the vicinity of operating mines with the goal of extending the lives of these operations mining, in which ore and concentrate are produced Mineral Processing Minesite12/01/2018 In mineral processing, a number of unit operations are required to prepare and classify ores before the valuable constituents can be separated or concentrated and then forwarded on for use or further treatment The field of mineral processing has also been given other titles such as mineral dressing, ore dressing, mineral extraction, mineral beneficiation, Introduction to Mineral Processing or Beneficiation

Industrie minière et traitement des minerais arkema

Extraction et traitement des minerais Nous sommes en mesure d’intervenir pour optimiser chaque étape du traitement des minéraux après leur extraction et réduire leur impact sur l’environnement : de la manipulation des suspensions au broyage en voie humide, jusqu’à la séparation par flottation ou autres technologies d’enrichissement26/12/2015 In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surface Less Crushing in Mineral Processing15/03/2019 Mineral processing simulators as a tool to implement watersaving strategies on the mine site The inclusion of water chemistry in a mineral processing simulator and the possibility to link the simulation platform to optimization algorithms provide a powerful tool that could be used to help implementing watersaving strategies on the mine siteWatersaving strategies in the mining industry – The

Mining Law Report 2022 Philippines ICLG

13/09/2021 The Mining Act and its IRR allow the sale of minerals locally and abroad, provided that the minerals and byproducts produced are sold at the highest market price and lowest commercially achievable commissions and related fees The mining contractor may enter into longterm sales and marketing contracts or foreign exchange and commodity hedging 17/02/2006 A conceptual model for metal recovery consisting of a mineral sands mining and gravity processing operation to recover free gold, magnetite and sulphides is being considered by the joint venture Testwork is now planned to obtain further details on processing alternatives for the gold and magnetite, as well as processing the sulphides to recover additional metal Mine Site Page 2 of 3 Incorporating MINEWS15/05/2014 Blasting can be described as the first stage of comminution carried out in the mine site in order to remove ores from their natural beds 11 A Bond Ball Mill Work Index test may be required for the design of a new mineral processing plant It is determined by Bond Ball Mill Grindability test in a lab using a Bond Mill Grindability is the number of net grams of ( screen ) Mineral Processing SlideShare

mineral processing minesite evidentmedpl

Acid mine drainage and minesite salinity are, arguably, the most serious threats posed to the environment by opencut mining and mineral processing 6 Stormwater mgt final waterwagovau Water Quality Protection Guidelines for Mining and Mineral Processing – Minesite stormwater Professional Mineral Processing equipment solutions JXSC Mining Machinery is an industrial mining equipment OEM ODM from China, with over 30 years of rich experience and unique knowledge, We help our customers around the world solve a variety of problems from crushing and screening all the way through tailings management in the aggregate Mineral Processing Equipment Solutions by JXSC Mining The processing sequence that turns Tronox’s mineral sands into finished products begins at the Chandala Processing Plant, located about 60 kilometers north of Perth The Chandala complex includes three major plants: a dry mill, which separates the minerals; a synthetic rutile plant, which upgrades ilmenite into highquality synthetic rutile; and a residue management plant Chandala Processing Plant Tronox

Metal ore mining in Europe Mineral Processing

This figure is derived from data published by Euromines (European Association of Mining Industries, Metal Ores Industrial Minerals) According to the latest figures from the US Geological Survey (USGS) in 2014, the EU accounts for the following shares in the global mining outputs: titanium ore 89 %, silver 71 %, zinc 52 %, lead 39 %, copper 37 %, nickel 27 %, 03/12/2021 Here is my list of the Top 15 largest and biggest mines in the world: They are economically big and physically large, taking a lot of time and power to excavate using special mining equipmentBut in their core, there’s what big mining companies are looking for: the precious ore Join us as we explore the world of the largest manmade canyons yetLargest Mines in the World Mineral Processing MetallurgyLarge processing capacity, thermal efficiency up to 60%; The drum dryer adopts “aligning roller device”, which greatly reduces wear and power loss; Contact Us Now Please fill out the contact form below to get the quotation price and engineer help We will response your request within 24 hours Your Name Your Phone or WhatsApp Your Company Processing Mineral Rotary Dryer Mineral Processing

Responsible Mining Zero Cyanide Mercury in Gold

We exist to bring an end to the use of Cyanide and Mercury in mineral processing of Gold and other metals Cyanide in Gold Silver Mining About 80% of the world’s gold production utilises cyanide in extraction, with about 2,500 tonnes of gold being produced annually worldwide^ Depending on the mineralogy, gold and other metals are extracted by physical processes such Mineral Resources started mining at the Mt Jackson pits in March 2020 and transitioned the Deception and Jackson pits to lowerstrip ore delivery phases by June 2020 The F3 pit is reaching the bottom of the orebody while access works and site clearing began on the F1 pit Mining at the Koolyanobbing operation was undertaken at a rate of six million tonnes per Koolyanobbing Iron Ore Mine, Australia Mining TechnologyWith our mining and mineral processing chemicals and support capabilities, we can help you establish new productivity benchmarks for your operation while maintaining high safety standards without the need for capital investment Our product portfolio includes a number of novel products for flocculation, scale control, grinding, dust control and rheology modification, which means Mining Mineral Processing Chemicals Solenis

MineSite Labs British Columbia PMC Ltd

Mineral Processing Operations; Mineralogical Capabilities ; Metallurgical Capabilities; MineSite Labs; About Us Our People; Contact Mining Cruise Careers Brochures and Case Studies News Client Downloads Goliath; More MineSite Labs Onsite mineralogical analysis provides near realtime diagnostics to unequivocally determine reasons for low grade or recovery Process 26 was contracted by Leighton Contractors to provide commissioning management services for their Design and Construct contract with Rio Tinto The project consisted of a 25 MTPa Iron Ore Crushing, Stacking and Train Loading facility and the associated Infrastructure Support facility Process 26 developed in conjunction with Leighton the management plan, Mesa A Minesite Commissioning Management Process 26Critical Minerals RD, Mineral Testing and Process Development Industry: Mining Minerals Industry: Mining Minerals Resource of the Week: Mining Production Equipment Brochure Rotary Kiln Gains Traction as EWaste Crisis Looms, Metal Recovery from EWaste Metal Processing Infographic Resource of the Week: Metals and Minerals Processing Mining Mineral Processing Equipment

Mine Site Incorporating MINEWS

04/04/2019 Mine Site Incorporating MINEWS Primary Menu Home; Contact ; About Us; Well Hello CEO: Top 15 Gold Stocks For 2020 Posted on April 4, 2019 November 30, 2021 by hankinstappan Gold production is an industry more people should be buying stock in Mining and other companies that focus on the production of gold are great to invest in because they’re not Locating the mineral processing plant near a mine is the most important parameter that affects the whole process Many factors, and their preferences, should be considered in this stage The factors include economical, geological, technical, environmental and tectonic parameters A multicriteria decision making method is necessary to rank the alternatives In this paper we Mineral processing plant location using the analytic 03/04/2019 Mine Site Incorporating MINEWS Primary Menu Home; Contact; About Us; 5 Reasons You Need To Invest In Mining Stocks In 2019 Posted on April 3, 2019 January 27, 2022 by hankinstappan While investing in mining stocks isn’t quite as popular as investing in tech, it still accounts for over 45% of the world GDP – mostly because natural resources are essential 5 Reasons You Need To Invest In Mining Stocks Minesite

Copper Mining Extraction Process Flow Chart

26/08/2015 Copper Mining Extraction Process Flow Chart This flowchart made of machinery icons explains or expresses in simple but clear terms the step of the Copper Mining and Copper Extraction Process Starting from either openpit or underground mining and using a different relevant treatment method for oxide or sulphide copper mineral (ore)The raw materials for Tronox’s titanium minerals business come from ancient shoreline deposits in the Lancelin to Gingin area, approximately 170 kilometers north of Perth Tronox’s mine in this area has the local indigenous name Cooljarloo Grains of valuable heavy minerals were deposited on ancient shorelines thousands of years ago, where the action of waves and wind Cooljarloo Mine TronoxLarge processing capacity, thermal efficiency up to 60%; The drum dryer adopts “aligning roller device”, which greatly reduces wear and power loss; Contact Us Now Please fill out the contact form below to get the quotation price and engineer help We will response your request within 24 hours Your Name Your Phone or WhatsApp Your Company Processing Mineral Rotary Dryer Mineral Processing