designing a site for ncrete batch plant r

2022-01-23T04:01:53+00:00

How to build a concrete batching plant

02/08/2021 Concrete batching plant design Concrete Batching Plant Design takes the concrete production requirements and creates a concrete batching plant to deliver the production requirements A Concrete Batching Plant is a piece of machinery that manufactures concrete Concrete consists of sand, aggregate, cement, water and addmixturesDesigning A Site For Concrete Batch Plant Concrete batch plant source epa ap42 figure 11121 june 2006 the cement silos are generally the most noticeable part of a concrete batch plant they will typically be very tall maybe three stories or 40 feet there will be several of them at some concrete batch plants there will be a silo that stores a supplemental mixture thatDesigning A Site For Concrete Batch Plantdesigning a site for concrete batch plant Again in , they needed to expand they considered using their existing concrete batch plant, but an incident caused eagle to rethink that plan coowner and production director kevin kooiker explains, our original batch plant had a large skip hoist to lift the aggregates from a conveyor to the mixerdesigning a site for concrete batch plant

designing a site for concrete batch plant

designing a site for concrete batch plant Again in , they needed to expand they considered using their existing concrete batch plant, but an incident caused eagle to rethink that plan coowner and production director kevin kooiker explains, our original batch plant had a large skip hoist to lift the aggregates from a conveyor to the mixer Send : [ protected] Get Concrete Batch Plants National Concrete Corporation Custom design allows for a concrete batch plant layout that makes the most efficient use of your site and permits the user to tailor storage and production rates specific to their markets We can supply central mix, transit mix, decumulative, and dribble batch concrete plant designs that designing a site for concrete batch plantThey considered using their existing concrete batch plant, but an incident caused Eagle to rethink that plan Coowner and production director Kevin Kooiker explains, “Our original batch plant had a large skip hoist to lift the aggregates from a conveyor to the mixer There was a flaw in the cable mechanism and just before the new expansion was completed, the skip hoist Concrete Batching Plant Design and Technology for Eagle

designing a site for concrete batch plant

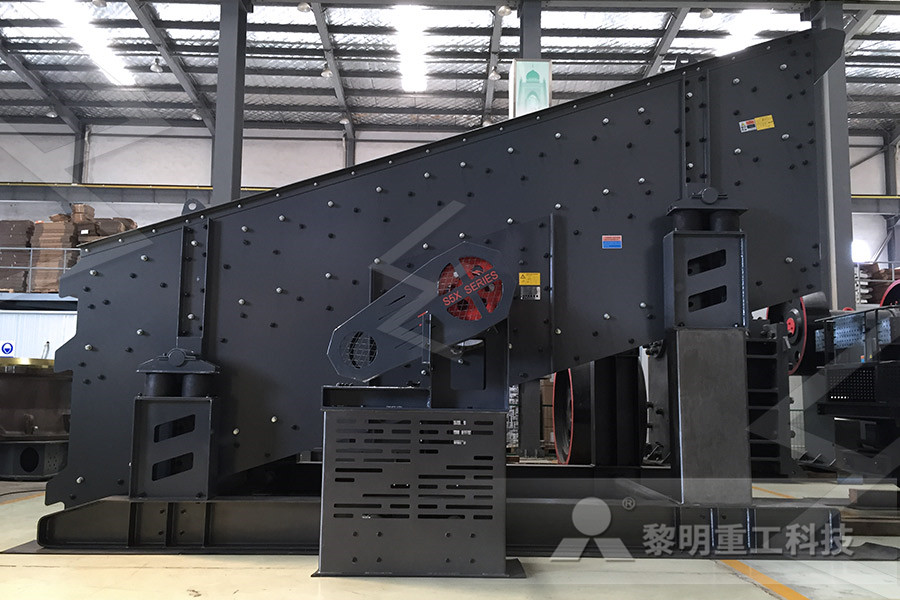

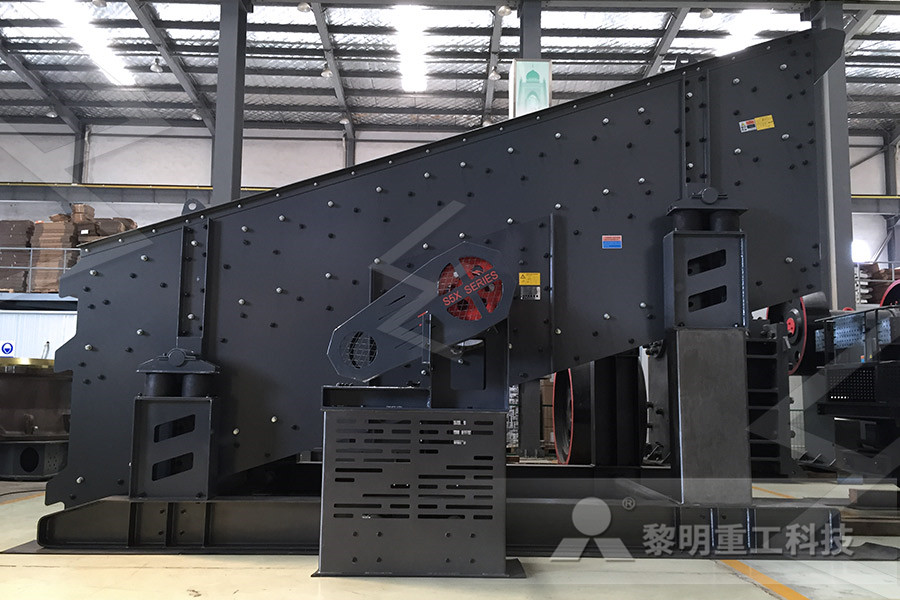

Portable Concrete Batch Plant Easy To Move, Install And Portable concrete batch plant is with tyres on the one side of belt conveyor, a semitrailer unit, so it is easy to move around It doesn't need to lay foundation, if you want to do another construction project, which is convenient to disassemble it and transfer it to another siteCustom design allows for a concrete batch plant layout that makes the most efficient use of your site and permits the user to tailor storage and production rates specific to their markets We can supply central mix, transit mix, decumulative, and dribble batch concrete plant designs that are suitable for any ready mix concreteConcrete Batch Plants National Concrete Corporation25/05/2017 Components of concrete batch mix plant A concrete batch mix plant has a number of parts and accessories that combine and work together to produce quality concrete Some of the major components are as below: Aggregate feeders – Feeding unit is one of the important component There are bins located side by side to facilitate feeding of coarse How does a concrete batch plant work Operation of

How to build a concrete batching plant

14/08/2021 When purchasing a concrete batching plant, the theoretical productivity of the concrete plant ought to be larger than we need For example, if projects’ required amount of concrete is 70 cubic meters per hour, then we should choose hzs90 concrete plant with a theoretical productivity of 90m³/h, instead of hzs75 concrete plant with 75m³/hDesigning A Site For Concrete Batch Plant Concrete batch plant source epa ap42 figure 11121 june 2006 the cement silos are generally the most noticeable part of a concrete batch plant they will typically be very tall maybe three stories or 40 feet there will be several of them at some concrete batch plants there will be a silo that stores a supplemental mixture thatDesigning A Site For Concrete Batch PlantBatch Ticket Reveals Mix Design Concrete Construction Jun 26 2014 0183 32 This is only 075 pounds of AEA for the almost 7 500 pounds of concrete in this batch for a weight ratio of 001 This miniscule weight percentage is why liquid admixtures cannot be batched on a weight basis they are usually measuredout in vials or graduated cylinders visible to the batch plantdesigning a site for concrete batch plant

site layout for batch concrete mixing plant a design of

Concrete Batching Plant UK Concrete Batching Plant UK Design We carry out a full design service from building a business case to drawing up the layout to suit your site The process begins with an analysis of your input costs and plant How does a concrete batch plant work May 25, 2017 Before we understand the working or operation of a concrete batch plantIt is Concrete Batching Plant Layout and Design At full capacity the twin C1800 batching plant layout delivers 480 m3 of concrete per day during an eighthour shift This capacity is ideal for a small to medium sized readymix concrete plant servicing a large site or a number of sites Get Price concrete batch plant industrial Concrete batch plant industrial products are most site plan for concrete batch plants artbelievefrPortable Concrete Batch Plant Easy To Move, Install And Portable concrete batch plant is with tyres on the one side of belt conveyor, a semitrailer unit, so it is easy to move around It doesn't need to lay foundation, if you want to do another construction project, which is convenient to disassemble it and transfer it to another sitedesigning a site for concrete batch plant

Setting up a ReadyMix Concrete Manufacturing Plant Ready

from a central plant instead of being mixed on the job site Each batch of readymixed concrete is tailormade according to the specifics of the contractor and is delivered to the contractor in a plastic condition, usually in the cylindrical trucks often known as "cement mixers" Readymixed concrete is particularly advantageous when small quantities of concrete or intermittent Concrete Batch Plants Besser concrete batch plants are innovative to meet the needs of today’s changing marketplace and built rugged, like all Besser machinery, to stand the test of time Quality Quality is the hallmark of Besser machinery Besser uses its expertise and resources to design customized plants to customer specific requirements Highly skilled staff follow the ConCrete BatCh Plants BesserWhen draining aggregates at the batch plant site, provide provisions for dis posal of drainage water and for clearcut separation of drained from undrained materials Keep materials of different sources/classes or gradations separated Sometim es, timber bulkheads are erect ed to save space in the Producer’s storage yard These are satisfactory if built properly Erect the BATCHING AND MIXING Minnesota Department of Transportation

What is a concrete batch plant? Big D Ready Mix

In a concrete batch plant, the various ingredients used to make the type of concrete being used — such as Portland cement, aggregates (gravel, crushed stone, sand, etc), and water — are combined in a large, mechanical, and sometimes computeraided machine, mixed and prepared for use at a job site The end product (concrete) is then put to use as a raw material in laying 14/08/2021 When purchasing a concrete batching plant, the theoretical productivity of the concrete plant ought to be larger than we need For example, if projects’ required amount of concrete is 70 cubic meters per hour, then we should choose hzs90 concrete plant with a theoretical productivity of 90m³/h, instead of hzs75 concrete plant with 75m³/hHow to build a concrete batching plantdesigning a site for concrete batch plant Again in , they needed to expand they considered using their existing concrete batch plant, but an incident caused eagle to rethink that plan coowner and production director kevin kooiker explains, our original batch plant had a large skip hoist to lift the aggregates from a conveyor to the mixerdesigning a site for concrete batch plant

designing a site for concrete batch plant

designing a site for concrete batch plant Again in , they needed to expand they considered using their existing concrete batch plant, but an incident caused eagle to rethink that plan coowner and production director kevin kooiker explains, our original batch plant had a large skip hoist to lift the aggregates from a conveyor to the mixer Send : [ protected] Get Concrete Batching Plant Layout and Design At full capacity the twin C1800 batching plant layout delivers 480 m3 of concrete per day during an eighthour shift This capacity is ideal for a small to medium sized readymix concrete plant servicing a large site or a number of sites Get Price concrete batch plant industrial Concrete batch plant industrial products are most site plan for concrete batch plants artbelievefrConcrete Batch Plants National Concrete Corporation Custom design allows for a concrete batch plant layout that makes the most efficient use of your site and permits the user to tailor storage and production rates specific to their markets We can supply central mix, transit mix, decumulative, and dribble batch concrete plant designs that designing a site for concrete batch plant

Concrete Batch Plants National Concrete Corporation

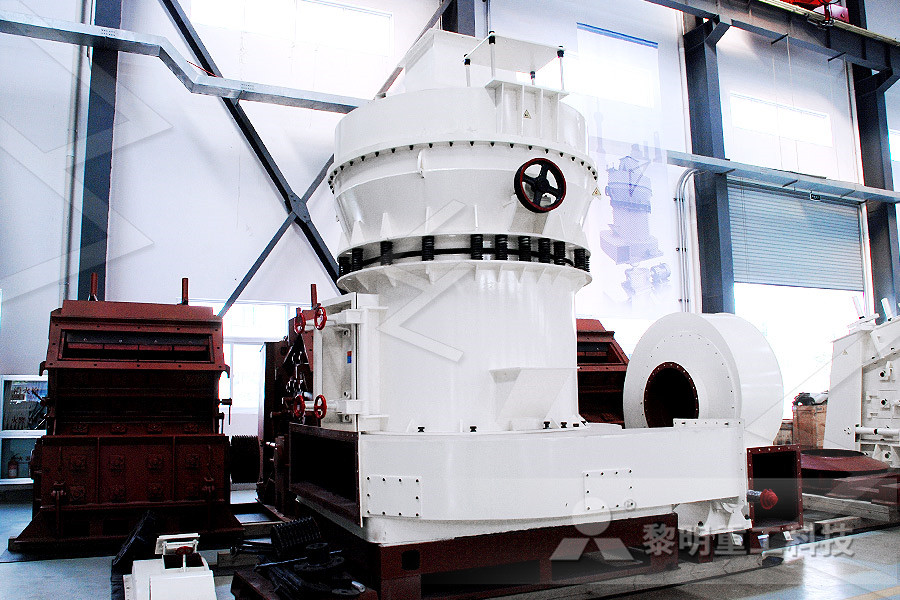

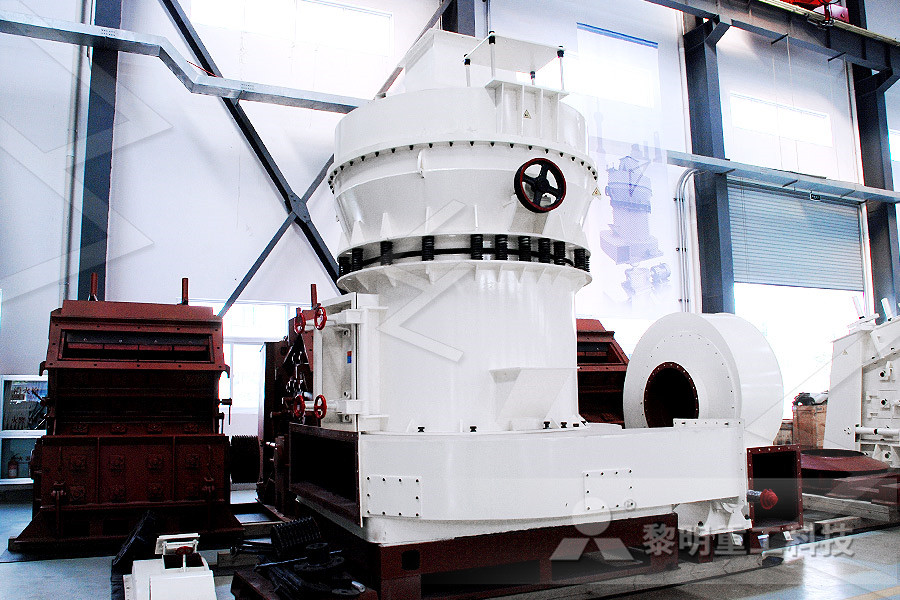

Corporation can custom design a concrete batch plant configuration to meet your specific production requirements Custom design allows for a concrete batch plant layout that makes the most efficient use of your site and permits the user to tailor storage and production rates specific to their markets We can supply central mix, transit mix, decumulative, and dribble Determine whether an onsite concrete batch plant should be utilized for concrete work from piles through level 2 slabs Furthermore, determine if an onsite bath plant alleviates coordination, delivery, site logistics, cost, and potential risk issues presented with typical concrete delivery from offsite batch plants In addition, the onsite batch plant must meet Implementing an OnSite Concrete Batch Plant on a Large from a central plant instead of being mixed on the job site Each batch of readymixed concrete is tailormade according to the specifics of the contractor and is delivered to the contractor in a plastic condition, usually in the cylindrical trucks often known as "cement mixers" Readymixed concrete is particularly advantageous when small quantities of concrete or intermittent Setting up a ReadyMix Concrete Manufacturing Plant Ready

designing a site for concrete batch plant

Portable Concrete Batch Plant Easy To Move, Install And Portable concrete batch plant is with tyres on the one side of belt conveyor, a semitrailer unit, so it is easy to move around It doesn't need to lay foundation, if you want to do another construction project, which is convenient to disassemble it and transfer it to another site25/05/2017 Components of concrete batch mix plant A concrete batch mix plant has a number of parts and accessories that combine and work together to produce quality concrete Some of the major components are as below: Aggregate feeders – Feeding unit is one of the important component There are bins located side by side to facilitate feeding of coarse How does a concrete batch plant work Operation of