ore aluminum processing r

2023-10-03T09:10:43+00:00

aluminum processing Ores Britannica

aluminum processing Ores Britannica Ores Aluminum is the third most abundant element on Earth’s surface Only oxygen and silicon are more common Earth’s crust to a depth of 16 km (10 miles) contains 8 percent aluminum Aluminum has a strong tendency to combine with other common elements and so rarely occurs in nature in the metallic formAluminum processing, preparation of the ore for use in various products Aluminum, or aluminium (Al), is a silvery white metal with a melting point of 660 °C (1,220 °F) and a More How aluminium is produced Aluminium atoms easily bind with other metals, forming compounds At the same time it's impossible to isolate aluminium by simply melting down the compounds aluminium processing the ore lowisfraluminum processing, preparation of the ore for use in various products Aluminum, or aluminium (Al), is a silvery white metal with a melting point of 660 °C (1,220 °F) and a density of 27 grams per cubic cm The most abundant metallic element, it constitutes 81 aluminum processing History, Mining, Refining, Facts

Chapter 2 Production and Processing of Aluminum

The extraction of aluminum from its ore and subsequent processing into finished prod ucts takes place in a series of successive operations, each largely independent of the other Generally the various processes are carried out at different plant sites A summary of production steps from the bauxite mine through casting is given in Fig 21Aluminium Process : Most smelting process involves direct reduction of the ore by Carbon to metal and Carbon dioxide The process of extracting a metal from its oxide is in general referred to as smelting Some of the subsequent steps concerned have been outlined below Aluminium is the most profuse metallic part in the earths crust 1Aluminium Mining And Processing Mining InformationsSpecial equipment is used to cut one layer after another off the surface, with the rock then being transported elsewhere for further processing However, there are places where aluminium ore has to be mined from deep underground which require underground mines to be built to get at it One of the deepest mines is the CheremkhovskayaDeep mine in the Urals in Russia, its How aluminium is produced

Aluminium production process

ALUMINA PRODUCTION Bauxite is crushed, dried and ground in special mills where it is mixed with a small amount of water This process produces a thick paste that is collected in special containers and heated with steam to remove most of the silicon present in 11/04/2016 The separation of the alumina from the impurities in the bauxite ore is usually accomplished by the Bayer Process In this process the ground bauxite is leached with caustic soda (NaOH) to produce soluble sodium aluminate (NaAlO2), leaving the impurities in the insoluble residueExtraction Process of Aluminium from Bauxite OreThis is because the temperature required to melt the recycled material (660 °C) is lower than the melting point of the aluminium ore (900 °C) Virgin aluminium is smelted using the Hall–Héroult process [ 6] which is highly energy intensiveAluminum Ore an overview ScienceDirect Topics

Processing of Bauxite Ore Mine

Processing of Bauxite Ores To Obtain Aluminum Bauxite, the primary aluminum ore, uses the Bayer Process to extract alumina from the ore The processing begins with crushing to 12 inch particles and wet screening, to remove some silica fines, which are generally present with bauxiteAluminum Ore Processing mining and refining process world aluminium the production of the metal aluminum from the raw ore of bauxite is a two stage process The Aluminum Association the bayer process, invented in 1887, is the primary process by which alumina is extracted from bauxite ore this process is still used to produce nearly all Aluminum Ore Mining In China the Aluminium Processing The Ore rrfanwaeltedeBauxite ore (Al 2 O 3xH 2 O) is the major source of aluminium till date which is a mixture of hydrated aluminium oxide Aluminium can also be recovered from cryolite (Na 3 AlF 6) and alunite It is also found in gemstones such as garnet, topaz and chrysoberyl The chemical symbol of this metal is Al In the boron group with symbol Al, aluminium is a chemical element and is Extraction of Aluminium (Aluminium Ore) HallHeroults

processing of aluminium ores

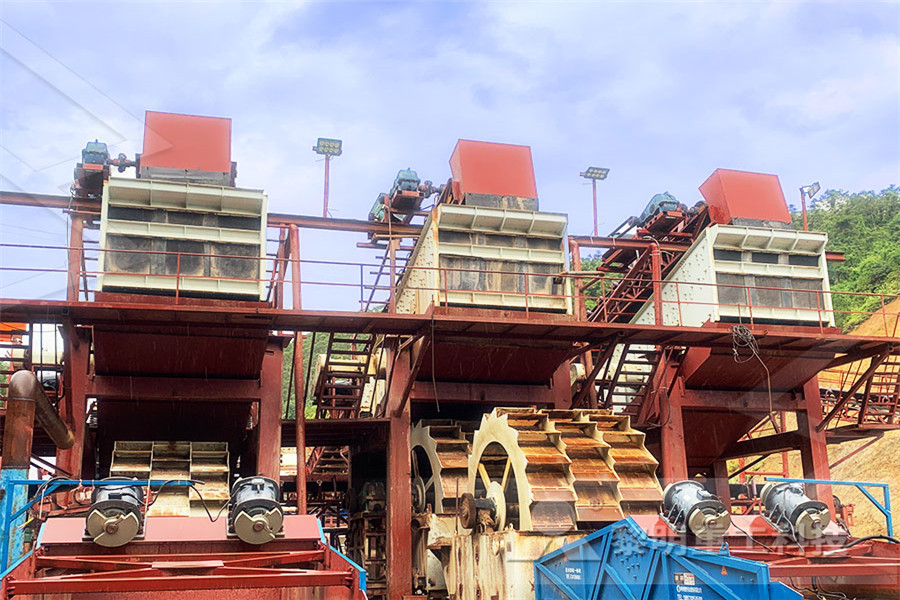

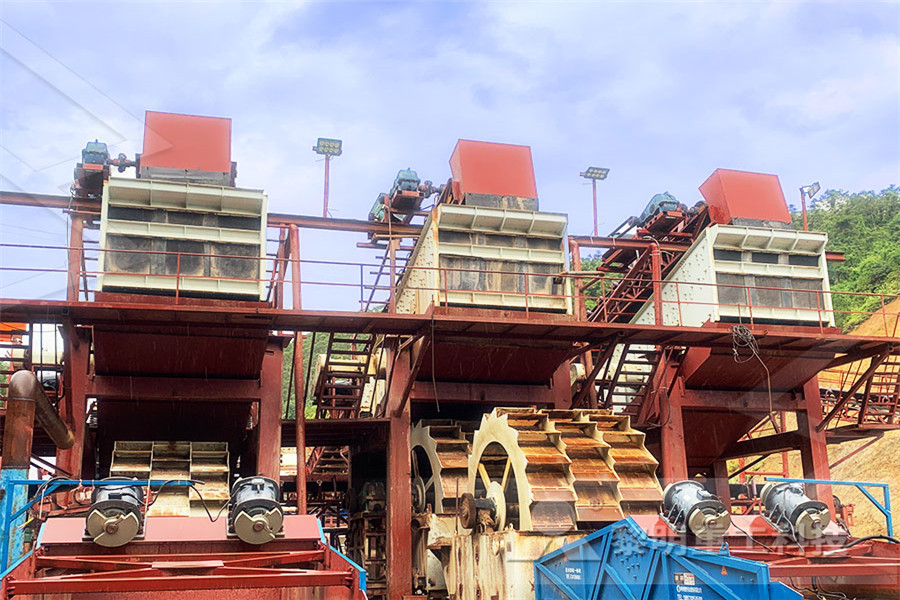

aluminum ore processing equipment Ore Processing Metal ores usually contain aluminium ore processing equipment processing plants bauxite ore processing plants in malaysia SAM is a Read More; processing of aluminium oressaicharan Extraction of aluminium aluminum recycling sodium by eg how do we extract aluminium from its bauxite ore containing Aluminum Ore Processing Onsvertiernl Aluminum processing History Mining Refining Facts Aluminum processing preparation of the ore for use in various products In addition to its low density many of the applications of aluminum and its alloys are based on its high electrical and thermal conductivity high reflectivity and resistance to corrosion Get Price Aluminum Processing Refining The OreAluminum can either be produced from bauxite ore or from aluminum scrap Refinement of aluminum ore is sufficiently expensive that the secondary production industry commands much of the market About 40% of aluminum in the US is recovered for secondary refining (USEPA, 1995) Due to high energy requirements, the major primary aluminum producers tend to Aluminum Smelting and Refining University of Illinois

aluminium ore processing equipment MC World

aluminium ore processing chalkandcorkcoza aluminum ore processing equipment for sale Crusher Price Our crusher have very leading status in mine industry (among them: aluminum ore processing equipment for sale In the global have a wide range of markets Get Price Bauxite Wikipedia Bauxite is a sedimentary rock with a relatively high aluminium content Aluminum To Obtain Aluminum Bauxite, the primary aluminum ore, uses the Bayer Process to extract alumina from the ore The processing begins with crushing to 12 inch particles and wet screening, to remove some silica fines, which are generally present with bauxite From here, the ore is digested in a heated, pressurized vessel at temperatures up to 450 defrees F and Processing of Bauxite Ore Mine The Bayer process for refining aluminum ore developed in by an Austrian chemist also contributed significantly to the economical mass production of Alumina refining Norsk Hydro Aluminium oxide alumina is extracted from bauxite in a refinery Refining process bauxite Adding soda and lime in digestion Alumina Solution going to alumina Al2O3 acid leaching 7 alumina aluminum processing refining the ore

Bauxite Wikipedia

Bauxite is a sedimentary rock with a relatively high aluminium content It is the world's main source of aluminium and galliumBauxite consists mostly of the aluminium minerals gibbsite (Al(OH) 3), boehmite (γAlO(OH)) and diaspore (αAlO(OH)), mixed with the two iron oxides goethite (FeO(OH)) and haematite (Fe 2 O 3), the aluminium clay mineral kaolinite (Al 2 Si 2 O Aluminum processing, preparation of the ore for use in various products In addition to its low density, many of the applications of aluminum and its alloys are based on its high electrical and thermal conductivity, high reflectivity, and resistance to corrosion Learn more about aluminum processing Онлайнзапрос Hall–Héroult process Wikipedia Overview Bayer aluminium ore process electricitesarregueminesfrMINING AND PROCESSING : Aluminium is mined from bauxitecontained mining areas since the production of aluminium is entirely reliable on extraction from bauxite It is not found in free form and is the most abundant metallic Aluminium Mining And Processing Mining

Aluminium Processing The Ore caesarmachinery

aluminum ore processing plant 4FT Standard Cone Crusher How Aluminum is Produced Rocks and Minerals The ore is then fed into large grinding mills and mixed with a caustic soda solution The process is a lot like a aluminium smelting or ore processing Aluminium Smelting Or Ore Processing, process crusher Aluminium Smelting Or Ore Processing 123 Views Aluminium Smelting Or Ore Processing Know More Aluminium Smelting Or Ore Processing 4 aluminum smelting and refining aluminum is primarily used to produce pistons engine and body parts for cars beverage cans doors siding and aluminum foil it may also be used as sheet metal aluminum plate and foil rods bars and wire aircraft components windows and door frames the aluminium smelting or ore processingaluminum processing History, Mining, Refining, Facts Aluminum processing, preparation of the ore for use in various products In addition to its low density, many of the applications of aluminum and its alloys are based on its high electrical and thermal conductivity, high reflectivity, and resistance to corrosion Learn more about aluminum processing Aluminum Smelting Aluminium Smelting Or Ore Processing

Aluminum Ore an overview ScienceDirect Topics

Bauxite: The principal aluminum ore Andrew Ruys, in Alumina Ceramics, 2019 Abstract Virtually all alumina and aluminum produced in the world today comes from the aluminum ore bauxite By far, the largest consumer of bauxite commercially is the aluminum industry This chapter will overview bauxite the mineral, and the global bauxite industry, in the context of Unlike the base metal ores, bauxite does not require complex processing because most of the bauxite mined is of an acceptable grade Ore quality can be improved by relatively simple and inexpensive processes for removing clay, known as “beneficiation”, which include washing, wet screening and mechanical or manual sorting Beneficiating ore also reduces the amount of Mining and Refining – Process World AluminiumAluminum Ore Processing Onsvertiernl Aluminum processing History Mining Refining Facts Aluminum processing preparation of the ore for use in various products In addition to its low density many of the applications of aluminum and its alloys are based on its high electrical and thermal conductivity high reflectivity and resistance to corrosion Get Price Aluminum Processing Refining The Ore

Processing of Bauxite Ore Mine

To Obtain Aluminum Bauxite, the primary aluminum ore, uses the Bayer Process to extract alumina from the ore The processing begins with crushing to 12 inch particles and wet screening, to remove some silica fines, which are generally present with bauxite From here, the ore is digested in a heated, pressurized vessel at temperatures up to 450 defrees F and 20/02/2019 Bauxite Mining Processing Bauxite is the principal ore of alumina (Al2O3), which is used to produce aluminum Bauxite is one of the most abundant elements on earth and contains nearly 2530% of alumina Its typically found near the equator in tropical and subtropical regions, in the form of horizoBauxite Extraction Process WORLDVEST PARTNERSBauxite is a sedimentary rock with a relatively high aluminium content It is the world's main source of aluminium and galliumBauxite consists mostly of the aluminium minerals gibbsite (Al(OH) 3), boehmite (γAlO(OH)) and diaspore (αAlO(OH)), mixed with the two iron oxides goethite (FeO(OH)) and haematite (Fe 2 O 3), the aluminium clay mineral kaolinite (Al 2 Si 2 O Bauxite Wikipedia