industry high capacity ball mill ceramic mill r

2021-01-24T12:01:50+00:00

Ceramic Ball Mill For Grinding Materials FTM Machinery

Materials that are grinded by ceramic ball mill can be made into porcelain and applied in the chemical industry Small production ball mill for ore grinding This is a 3foot by 6foot continuous ball mill, and this machine will process one ton an hour at 65 meshmill ceramic ball mill for ceramic industry high capacity energy saving overflowing type ball mill for ceramic industry US $4500$ set set CN shenyang huayue brilliant machineryequipment Co ltd yrs 889% contact supplier ad 16 ball mills sold by fote machinery manufacturer are unique in the following aspects the product ball mill grinding industry high capacity ball mill ceramic mill13/02/2017 CERAMIC LINED BALL MILL Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′ High density ceramic linings of uniform hardness male possible thinner linings and greater and more effective grinding volume Mills are shipped with liners installed Ceramic Ball Mills Mineral Processing Metallurgy

Ceramic Ball mill, ball mill for feldspar, ball grinding

23 lignes Ceramic Ball mill Ceramic ball mill is a kind of the best solution and specifically High quality Industrial Small Ball Mill For Ceramics , High Capacity Cement Ball Mill from China, China's leading ball mill equipment product, with strict quality control ball mill grinder factories, producing high quality ball mill grinder productsIndustrial Small Ball Mill For Ceramics , High Capacity Ceramic Ball Mill Google Sites ceramic liner ball mill adopts high aluminum material to make its lining, fastened high ceramic inside of barrel to protect barrel of ball mill ceramic liner ball mill applies to glass industry, ceramic, etc this type ball mill could effectively cut iron pollution base on substantial practices, we have been successfully manufactured lots andindustry high capacity ball mill ceramic mill

Industrial Ball Mills: Steel Ball Mills and Lined Ball

Ball Mills Steel Ball Mills Lined Ball Mills Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800’s The basic construction of a ball mill is a cylindrical container with journals at its axis The cylinder is filled with grinding media (ceramic or metallic balls Ball mill horizontal for ceramic for the Find out all of the information about the Ceramic Instruments Srl product ball mill horizontal for ceramic for the pharmaceutical industry MAG3000C Contact a supplier or the parent company directly to get a quote or to find out a price or your closest point of sale ball mill for ceramic industry praediafrHigh Capacity Ball Mill Ceramic FOB Reference Price:Get Latest Price Ceramic ball mill is mainly used in material mixing grinding Henan Fote Heavy Machinery Co Ltd has two kinds of grinding ceramic ball mill one is dry grinding ceramic ball mill and another is wet grinding ceramic ball mill READ MORE high efficiency ceramic dry grinding ball mill High high capacity ball mill ceramic rossrenovationfr

Ball Mill an overview ScienceDirect Topics

The terms highspeed vibration milling (HSVM), highspeed ball milling (H), and planetary ball mill (PBM) are often used The commercial apparatus are PBMs Fritsch P5 and Fritsch Pulverisettes 6 and 7 classic line, the Retsch shaker (or mixer) mills ZM1, MM200, MM400, AS200, the Spex 8000, 6750 freezer/mill SPEX CertiPrep, and the SWH04 vibrational ball Industry High Capacity Ball Mill Ceramic Mill Ball mill machine grinding ball mill grinder machine manufacturer supplier in china offering high quality vibrating wet type ceramic grinding ball mill machine large grinding ball mill machine with iso and ce approval ceramic rubber composited liners plate mat lining pad panel and so on Get Price List Chat Online Ceramic Industry High Capacity Ball Mill Ceramic MillWe provide ball mill machine for cement plant, power plant, mining industry, metallurgy industry, etc Ball mill machine can grind a wide range of materials, with enough continuous production capacity, simple maintenance Capacity range from 5t/h to 210t/h The feeding size is less than or equal to 30mm Learn moreBall Mill for Sale Mining and Cement Milling Equipment

Ball Mill RETSCH powerful grinding and homogenization

The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming effects These ball mills are also suitable for mechano chemistry Mixer Mills grind and homogenize Batch Type Ceramic Ball Mill Suitable Made in Product description Ball mill 01~100 ton capacity wet batch type, suitable for glaze and the ceramic raw materials milling The lining materials canhigh capacity type china ball mill for ceramic industry「high capacity type china ball mill for ceramic industry」Rotary ball mill is composed of feeding part, discharging part, turning part, transmission part (reducer, small transmission gear, motor, electric control) and other main parts The hollow shaft of the rotary ball mill is made of cast steel, and the lining can be removed and replaced The large rotary gear is processed by casting hobbing, and the cylinder body is equipped with a Rotary Ball Mill for High Uniformity Grinding of

Ball Mill Design/Power Calculation

19/06/2015 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type ceramic ball mill for grinding materials ftm machinery What kind of materials that the ceramic ball mills can process are always the focus of the miners Can they show the safety and high efficiency? Does it really meet the demands or special demands of customers? The ceramic ball mill is a small ball mill mainly used for mixing and grinding material In ball mill ceramic ball mill for ceramic industry Hot Sale 200kg High Capacity Ball Mill Used For Grinding Mine industry etc wet and dry grinding of , cement,Ball mill is essential equipment used for crushing and grinding raw material it is widely used in ceramic, fertilizer, glass Ball Mill Ceramics Industry Crusher Mills Cone Crusher Is a jointstock enterprise integrating rampd, manufacturing and marketing in china ceramic industriesceramic industry ball mill

ball mill for ceramic industry maraisdevertonfr

Materials Grinding Ball Mill For Ceramic Industry Ceramic Ball Mill is mainly used for mixing milling of the material the fineness even saving force Wet type ball mill are mostly used in the industry production It is to increase the high grinding efficiency under the ball mill grinding and striking from which the granularity is even and no flying dust with little noise being the mostBall mill horizontal for ceramic for the Find out all of the information about the Ceramic Instruments Srl product ball mill horizontal for ceramic for the pharmaceutical industry MAG3000C Contact a supplier or the parent company directly to get a quote or to find out a price or your closest point of sale ball mill for ceramic industry praediafrChina High Alumina Ceramic Ball Mill Grinding Jar China Alumina Ceramic Jars with Lids, Al2O3 Porcelain Jar Mill, Alumina Porcelain Milling Jar manufacturer / supplier in China, offering High Alumina Ceramic Ball Mill Grinding Jar, Ceramic Crucible NonStandard Customized Melting Pot Customizable for Industrial Use, Glazed Steatite Ceramic Cap with M5 or M6 high durability big capacity ceramic grinding ball mill

use of ball mill in ceramic industry

How to use ceramic grinding ball in ball mill of cement When loading the mill with empty warehouse, add materials first and then add the ceramic balls China's cement industry has been forced to eliminate the ball mill below 3 meters, so all enterprises in the grinding ball assembly mill, are using electric hoist, lifting and unloading, the drop is more than 3 get priceBall Mill For Ceramic Industry Yeshairparrucchieri Ceramic clay ball mill ceramic clay ball mill suppliers andAlibaba offers 168 ceramic clay ball mill productsAbout 75 of these are mine mill 5 are grinding equipmentA wide variety of ceramic clay ball mill options are available to you such as condition local service location and get priceball mill for ceramic industry sistemafiitHigh efficiency ball mill for ceramic industry production line Ceramic Clay Ball Mill, Ceramic Clay Ball Mill Suppliers Nov 07, 2018 Sponsored Listing High safety and energy saving ceramic clay ball mill Ceramic clay ball mill application 1The ball mill plays an important role in grinding the crushed materials 2The ball mill is widely used in cement, silicate products, Ball Mill For Ceramic Industry salondotykpieknapl

Ball Mills an overview ScienceDirect Topics

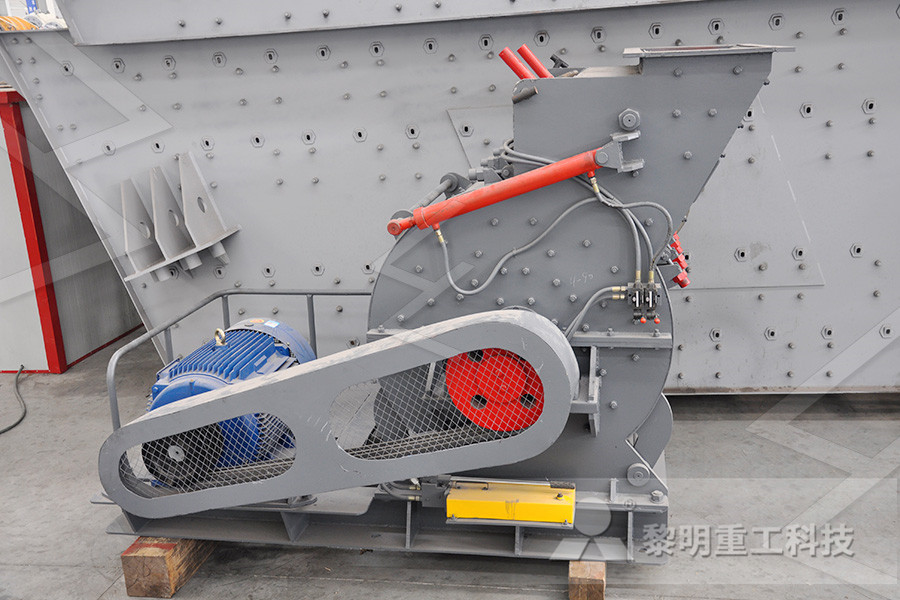

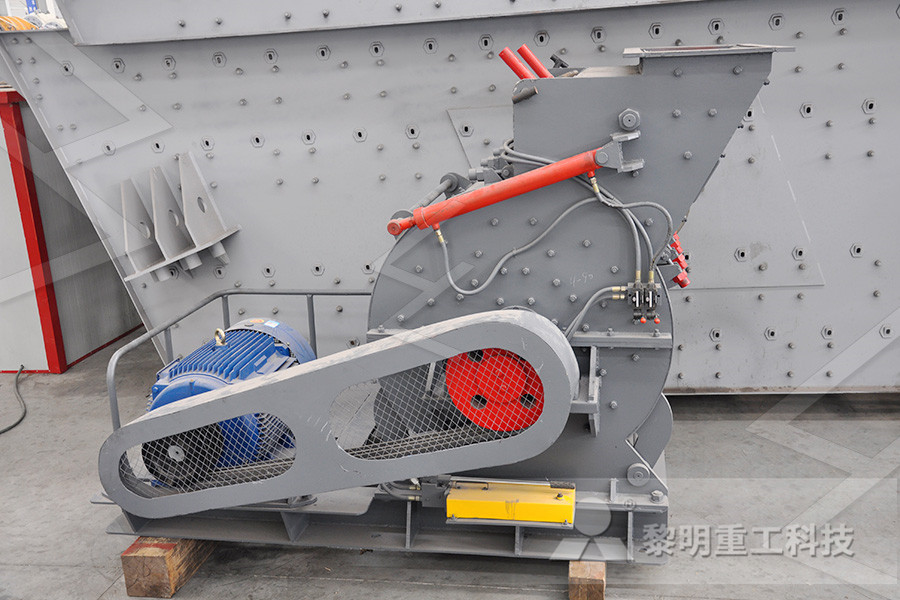

8322 Ball mills The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter ( Figure 811) The feed can be dry, with less than 3% moisture to minimize ball Rotary ball mill is composed of feeding part, discharging part, turning part, transmission part (reducer, small transmission gear, motor, electric control) and other main parts The hollow shaft of the rotary ball mill is made of cast steel, and the lining can be removed and replaced The large rotary gear is processed by casting hobbing, and the cylinder body is equipped with a Rotary Ball Mill for High Uniformity Grinding of