Coal Conveyor System Design Zimbabwe r

2023-11-16T15:11:48+00:00

Coal Conveyor Crushering System waltercomde

Conveyor amp crushing mill creek engineering,millcreek provided detailed design of a covered twosegment overland conveyor system used to transport million tpy of coal combustion residuals over 7,400 linear feet at 1400 tph from the power plant to the landfill feeders, stacking equipment, and transfer points were strategically placed to minimize material handling06/07/2015 CWW offers complete sales and support The system will comprise five conveyors ranging in length from 2,7 km up to 6,1 km Optimum Colliery is a major coalmining operation in the BHP Billiton Energy Coal group, situated in the Witbank Coalfield area of South Africa, producing mainly coal for SA Mennie, a 78yearold mechanical engineer living in Parksville, belt design: Coal Conveyor Systems02/01/2021 Figure16 illustrates the amount of coal on the conveyor system that lead to this failure This problem was solved by increasing the pressure in the hydraulic line driving the motor, and mounting a series of small diameter rollers underneath the conveyor belt to reduce friction between the belt and the bedplate An apparently minor, but persistent problem, was the Conveyor Design for Mining Machines 911 Metallurgist

An Intelligent Conveyor Control System For Coal Handling

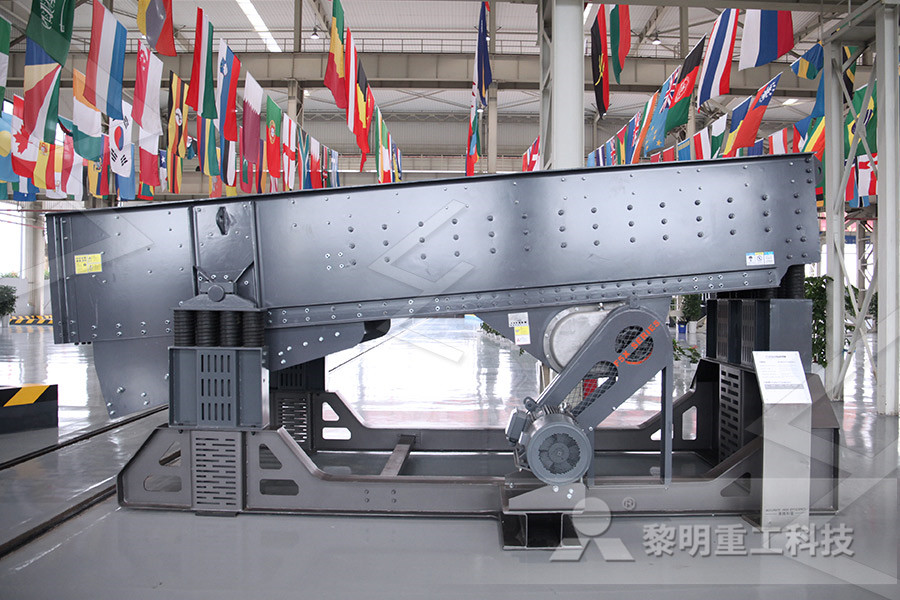

If a conveyor system is working well, it is almost invisible to the CHP A single conveyor can run at close to 100% reliability, but as the number of conveyor increases, the reliability of the conveyor system is mostly depend upon its control system The control system should be capable to fulfill all the need of CHP operation The existing systems are designed to take 18 Dust Suppression System and Dust Collection System 185 19 Magaldi Superbelt 204 20 Belt Training / Tracking 206 21 Steep Angle Conveying 223 22 Pipe Conveyor 241 23 Safety 250 24 Trouble Shooting 261 25 Maintenance Tools and Recommendations 267 References 269 3 Construction and Maintenance of Belt Conveyors for Coal and Bulk Material Handling Plants Construction and Maintenance of Belt Conveyors for Coal 24/02/2021 When considering how to design a conveyor system of this type, it’s important to consider the static load of the weighing platform and what the instantaneous load on it at maximum throughput may be to enable the correct specification of the load cell ranges For example, a lightweight cooked product may only need a load cell of a 2kg but a large How to design a conveyor system fegglobal

Coal Conveyors TECHFAB Systems

DTS System permanently monitor the entire conveyor belt and coal bunker infrastructure within the power plant and the software interfaces enabled easy integration in the central control room BENEFITS: Detects, locates and monitors fires or stationary heat buildup of conveyor systems and materials; Continuous linear fire and heat detection up to 16km – no gaps in coverage; The need for accuracy in the design and prefabrication of the feeder system and chutes to fit the existing structures was extremely important to meet the plant’s capacity flow of 300 TPH of 2” minus coal Recommendations/Solution: ASGCO ® engineers would provide an onsite Point Cloud Scanning survey to provideCoal Industry Conveyor Coal Conveyor Products Conveyor A single conveyor can run at close to 100% reliability, but as the number of conveyor increases, the reliability of the conveyor belt system is mostly depend upon its control system The control system has sensing device like zero speed sensing, receiving conveyor position sensing It has also facility for selection to operate conveyor avoiding control system ie manual run mod In Conveyor Belt System COAL HANDLING PLANTS

Coal Conveyor Crushering System waltercomde

Conveyor amp crushing mill creek engineering,millcreek provided detailed design of a covered twosegment overland conveyor system used to transport million tpy of coal combustion residuals over 7,400 linear feet at 1400 tph from the power plant to the landfill feeders, stacking equipment, and transfer points were strategically placed to minimize material handling25/02/2021 Design, Analysis and Optimisation of Belt Conveyor for Coal Application Abstract–The aim of this paper is to study existing Belt conveyor system and optimize certain specifications like reducing the vibrations, increasing the fatigue cycles, minimizing the weight and reducing deflection of drive shaft The paper also includes simulation and Design, Analysis and Optimisation of Belt Conveyor for 28/02/2019 Design of material handling system belt conveyor system for crushed coal for power plant 1 DOMS Material Handling System 1 Project Report on “DESIGN OF MATERIAL HANDLING SYSTEMBELT CONVEYOR SYSTEM FOR CRUSHED COAL FOR POWER PLANT” Submitted By Suhas Bandal (S38) Aditya Deshpande (S42) Pushpal Gavali (W02) Design of material handling system belt conveyor system

Conveyor Belt System COAL HANDLING PLANTS

A single conveyor can run at close to 100% reliability, but as the number of conveyor increases, the reliability of the conveyor belt system is mostly depend upon its control system The control system has sensing device like zero speed sensing, receiving conveyor position sensing It has also facility for selection to operate conveyor avoiding control system ie manual run mod In We design your conveyor system layout to provide for the correct transfer heights and feed areas onto the conveyors This allows modelling of the correct shape and size of chutes, resulting in a good flow of material Other offerings Products Learn more Services Learn more Solutions Learn more Keep exploring Stories from News 20 December 2021 Mine conveyors delivering productivity Conveyor Systems Facet Engineering specializes in the design and manufacture of conveyor systems to suit a wide range of product applications and handling requirements We manufacture and supply one of the largest ranges of conveyors in South Africa, servicing virtually all industries and sectors of the market From individual conveyors to complete turnkey conveyor systems, Turnkey Conveyor Systems Conveyors Facet Engineering

ContiTech Conveyor Belt Group Mining Technology

Extensively revised: An updated version of the 'Conveyor Belts System Design Calculations' manual from ContiTech is now available It has been extended to include additional products such as tube conveyor belts 1 October 2014 ContiTech Conveyor Belts Enable Safe Coal Transport Within the Port Coal mining plays a major role in the Australian economy Ten percent of all This standard has basically covered the conveyor system using belts from 300 mm to 2 000 mm belt widths conforming to IS 1891 (Part 1) : 1994 'Conveyor and elevator textile belting : Part 1 General purpose belting (fourth revision)' At present belts of width upto 3 000 mm are also being used in Indian industries This standard can be made applicable to belts of all widths subject to IS 11592 (2000): Selection and Design of Belt Conveyors They can be used to sample coal, coke, crushed stone and a variety of ores, and can be easily retrofitted to your existing conveyer via a straightforward installation procedure Naturally, all our Cross Belt Sampling Systems come with the backing of and JBLCo’s integrated design and manufacturing capabilities You’ll benefit from Cross Belt Sampling Systems

Aggregate Railcar Unloading Conveyor Systems

Using our standard enclosed conveyor system design this unit minimizes material loss and environmental impact Cambelt’s ScorpionⓇ 1210 can unload quick in small compact unit Download brochure ScorpionⓇ 3015 The ScorpionⓇ 3015 offers material transfer rates up to 8,500 cubic feet per hour using a 74hp tier 4 diesel engine At just under 26feet centerline spare part belt conveyor coal in zimbabwe Spare Part Fertilizer Machine and coal burner Hammer Pulverizer coal Liner Pulverizer coal Bearing adapter Pulverizer coal Belt Conveyor Connector Belt Conveyor Roller Belt ConveyorAs a leading global manufacturer of crushing equipment, milling equipment,dressing equipment,drying equipment and briquette equipment spare part belt conveyor coal in zimbabweconveyors and equipment zimbabwe Established in the year 2001, we, Precision Conveyor Systems, are amongst the wellknown names in manufacturing and supplying an exhaustive range of Precision Conveyor Systemss amp material handling equipment such as conveyors, chain conveyor, roller chain conveyor, industrial chain conveyor and rotating equipmentconveyors and equipment zimbabwe

Design, Analysis and Optimization of Drag Chain Conveyor

06/03/2020 Design, Analysis and Optimization of Drag Chain Conveyor System for Coal Application written by Unmesh Nandkishor Gatade , Gaurav Vishvanath Thote , Vikaskumar Omnarayan Yadav published on 2020/06/03 download full article with reference data and citations01/03/1993 @misc{etde, title = {Conveyor belt engineering for the coal and mineral mining industries} author = {White, L} abstractNote = {In conjunction with its 1993 annual meeting, SPE sponsored a symposium on conveyor belt engineering at which eighteen papers were presented in four sessions entitled: low tension drives; high tension drives; novel techniques; Conveyor belt engineering for the coal and mineral mining 24/04/2013 Of course with a conveyor that may run for miles, there are many design considerations to take into account; all of which will impact on longterm reliability, availability and maintenance requirements Transporting vast tonnages of coal overland, particularly where there are inclines involved, requires the highest levels of expertise in sophisticated conveyor and Brakes vital to overland coal conveyors Engineer Live

Fire detection and sprinklers control system for inclined

sprinkler system On the basis of the analysis carried out in order to protect the inclined coal conveyor against fires, we designed a fire detection, alarm and extinguishing control system (FDAECS) The protection extends along the inclined coal conveyors system, within which we used linear thermal detectors (sensor cables) and manual call 16/01/2014 This paper discusses the design calculations and considerations of belt conveyor system for limestone using 3 rolls idlers, in terms of size, length, capacity and speed, roller diameter, power and Design of a Material Handling Equipment: Belt Conveyor Using our standard enclosed conveyor system design this unit minimizes material loss and environmental impact Cambelt’s ScorpionⓇ 1210 can unload quick in small compact unit Download brochure ScorpionⓇ 3015 The ScorpionⓇ 3015 offers material transfer rates up to 8,500 cubic feet per hour using a 74hp tier 4 diesel engine At just under 26feet centerline Aggregate Railcar Unloading Conveyor Systems

(PDF) Design of coal mine drainage system ResearchGate

Design map of coal mine drainage system based on water catchment areas, rainfall data, runoff discharge, and information on rain intensity/frequency 5 They can be used to sample coal, coke, crushed stone and a variety of ores, and can be easily retrofitted to your existing conveyer via a straightforward installation procedure Naturally, all our Cross Belt Sampling Systems come with the backing of and JBLCo’s integrated design and manufacturing capabilities You’ll benefit from Cross Belt Sampling Systems