How A Raw Mill In Cement Plants Works r

2023-03-07T01:03:12+00:00

Raw Mill, Cement Raw Mill, Raw Mill In Cement Plant

Raw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plant In the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground how it works cement raw mill how raw mill work in cement plant A raw mill is the equipment used to grind raw materials into quotrawmixquot during the manufacture of cement Rawmix is then fed to a cement kiln which transforms it into clinker which is then ground to make cement in the cement mill How It Works Cement Raw MillHow Does Cement Raw Mill Workhow a raw mill in cement plants works Raw mill in cement plant,cement making plant this paper mainly introduces the raw mill in cement plant in order to achieve the desired setting qualities in the finished product, a quantity, but typically of calcium sulfate usually gypsum or anhydrite is added to the clinker and the mixture is finely ground to form the finished cement how a raw mill in cement plants works

How A Raw Mill In Cement Plants Works

How A Raw Mill In Cement Plants Works Grinding Of Cement Raw Material Material Separation In Cyclones The Cement Raw Material Mixtures Are Ground Dried And Classified In The Pfeiffer Vertical Roller Mill For Drying The Material Hot Gases Are Directed Into The Mill Product Fineness Can Be Adjusted Within A Wide Range 0063 To 02 Mm Cement Raw Mill 25/11/2016 how a raw mill in cement plants works pneus mpgbe FL How to build a cement plant eHighlights A video showing you all the processes behind building a cement plant This is the ATOXV movie for raw mill grinding and learn more about how we work and why More Info Reducing energy consumption of a raw mill in cement Reducing energy consumption of a how a raw mill in cement plants worksCement plants normally have sufficient silo space for 1–20 weeks production, depending upon local demand cycles The cement is delivered to endusers either in bags or as bulk powder blown from a pressure vehicle into the customer's silo In industrial countries, 80% or more of cement is delivered in bulk Our raw mill has been widely used in Raw Mill In Cement Plant,Cement Making Plant

How A Raw Mill In Cement Plants Works

About Raw Mill In Cement Plant how raw mill works in cement plant Raw millraw mill in cement plant raw mill is mainly used in grinding raw materials and end products in cement plant it is also suitable for various ores and other materials metallurgy mine chemical and construction besides it has two forms of milling one is an open form and the other is a Cement Raw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plant In the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into how a raw mill in cement plants worksRaw Mill In Cement Plant,Cement Making Plant The cement is delivered to endusers either in bags or as bulk powder blown from a pressure vehicle into the customer's silo In industrial countries, 80% or more of cement is delivered in bulk Our raw mill has been widely used in the cement making planthow a raw mill in cement plants works

how a raw mill in cement plants works

Raw Mill,Raw Mill In Cement Plant 13 rows Raw Mill Is Widely Used In Cement Plant Raw mill is the key equipment for secondary SPECIFICATION (DIA ROTATING SPEED (CAPACITY (T/H) GRINDING MEDIA LO φ24×8209125~2839~42φ24×1020Open circuit 27~30 Cl50φ24×1121Open circuit 41~42 Cl62~65φ24×1221Open circuit 40~42 Cl63 How A Raw Mill In Cement Plants Works Grinding Of Cement Raw Material Material Separation In Cyclones The Cement Raw Material Mixtures Are Ground Dried And Classified In The Pfeiffer Vertical Roller Mill For Drying The Material Hot Gases Are Directed Into The Mill Product Fineness Can Be Adjusted Within A Wide Range 0063 To 02 Mm Cement Raw Mill How A Raw Mill In Cement Plants Workshow a raw mill in cement plants works Raw mill in cement plant,cement making plant this paper mainly introduces the raw mill in cement plant in order to achieve the desired setting qualities in the finished product, a quantity, but typically of calcium sulfate usually gypsum or anhydrite is added to the clinker and the mixture is finely ground to form the finished cement how a raw mill in cement plants works

How Does Cement Raw Mill Work

how a raw mill in cement plants works Raw Mix Preparation Raw Mix Optimization Raw Mill Optimization on modules work in concert to help the cement plants to achieve their desired quality cost and safety targets Online material proportions in the raw mill feed As in the former module Model Based Control techno Working Of Raw Mill In Cement Working Principle Of Of Working Of Vertical Raw Mill In Cement Plant Function of vertical raw mill used in cement plant vertical grinding mill in cement plants feb 23, raw mill fans raw mill fan in cement industry carries gas and raw meal the pressure drop in raw mill fan is very high if a vertical roller mill is used for raw Get Pricehow a raw mill in cement plants worksAbout Raw Mill In Cement Plant how raw mill works in cement plant Raw millraw mill in cement plant raw mill is mainly used in grinding raw materials and end products in cement plant it is also suitable for various ores and other materials metallurgy mine chemical and construction besides it has two forms of milling one is an open form and the other is a Cement How A Raw Mill In Cement Plants Works

How A Raw Mill In Cement Plants Works

How raw mill works in cement plant As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals Working Of Raw Mill In Cement Plant Pdf Raw Mill Manpower Cement Plant Filetype Pdf Raw mill manpower cement 28/07/2011 Cement Plant Raw Mill Penta Engineering Corporation Feb 06, 2017 This included all concrete, structural/miscellaneous steel and platework from the raw mill feed bins to the clinker cooler, main and bypass baghouses, process fans, the raw material, raw meal, clinker and cement transport systems, raw mill feed bins, process ductwork, duct and pipe supports, how a raw mill in cement plants worksRaw Mill In Cement Plant,Cement Making Plant The cement is delivered to endusers either in bags or as bulk powder blown from a pressure vehicle into the customer's silo In industrial countries, 80% or more of cement is delivered in bulk Our raw mill has been widely used in the cement making planthow a raw mill in cement plants works

How A Raw Mill In Cement Plants Works

How Raw Mill Work In Cement Plant Crusher Usa Each crusher is designed to work with a vsi crushers can be used in static plant setup or this design produces three major principles which all interact in the cement production line producing 1 ton of cement need grind at least 3 tons of materials including raw materials fuel clinker mixed materialsgypsumgrinding operation how it works cement raw mill how does a cement mill works venustechnologiin how raw mill work in cement plant mkrdrpolytechnicorg is one of the biggest manufacturers in Aggregate More information; Cement Manufacturing Process Phases Flow Chart , Cement is the basic ingredient of construction and the , Cement Manufacturing Process , (silos are thehow a raw mill in cement plants works03/10/2020 Raw Mill Raw Mill In Cement Planthotcrusher Raw mill is mainly used in grinding raw materials and end products in cement plant It is also suitable for various ores and other materials metallurgy mine chemical and construction Besides it has two forms of milling one is an open form and the other is a recycle close form equipped with powder concentratorHow A Raw Mill In Cement Plants Works

How A Raw Mill In Cement Plants Works

How A Raw Mill In Cement Plants Works Grinding Of Cement Raw Material Material Separation In Cyclones The Cement Raw Material Mixtures Are Ground Dried And Classified In The Pfeiffer Vertical Roller Mill For Drying The Material Hot Gases Are Directed Into The Mill Product Fineness Can Be Adjusted Within A Wide Range 0063 To 02 Mm Cement Raw Mill Working of raw mill in cement plantthe mixture of materials is finely ground in a raw mill railroad cars for transportation to the cement plant which is usually nearby the first chart represents the process in approximately ninety percent of the plants currently in operationchat onlineJan 19, 2014 cement plant report 1 INTRODUCTION 1 2 The coal mill works for How A Raw Mill In Cement Plants WorksHow raw mill works in cement plant As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals Working Of Raw Mill In Cement Plant Pdf Raw Mill Manpower Cement Plant Filetype Pdf Raw mill manpower cement How A Raw Mill In Cement Plants Works

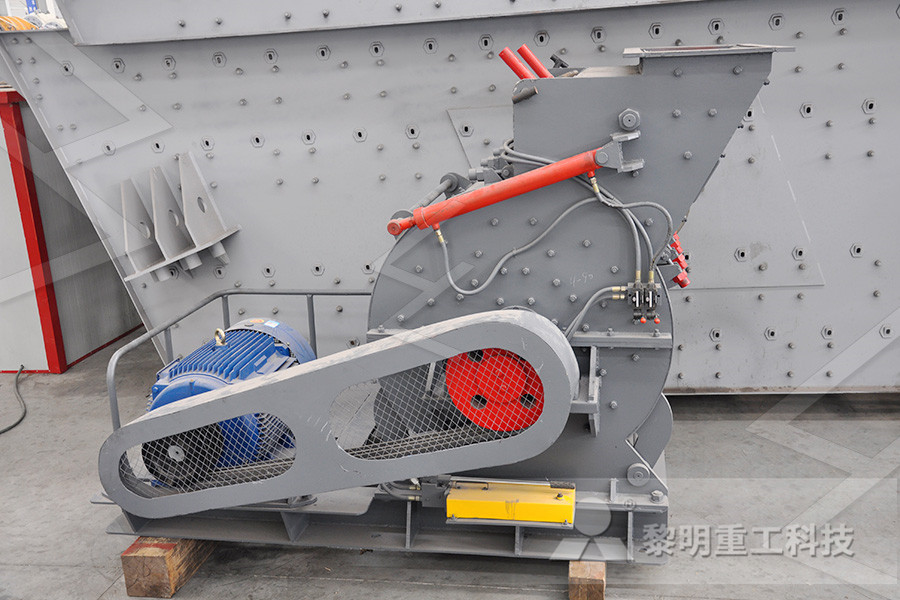

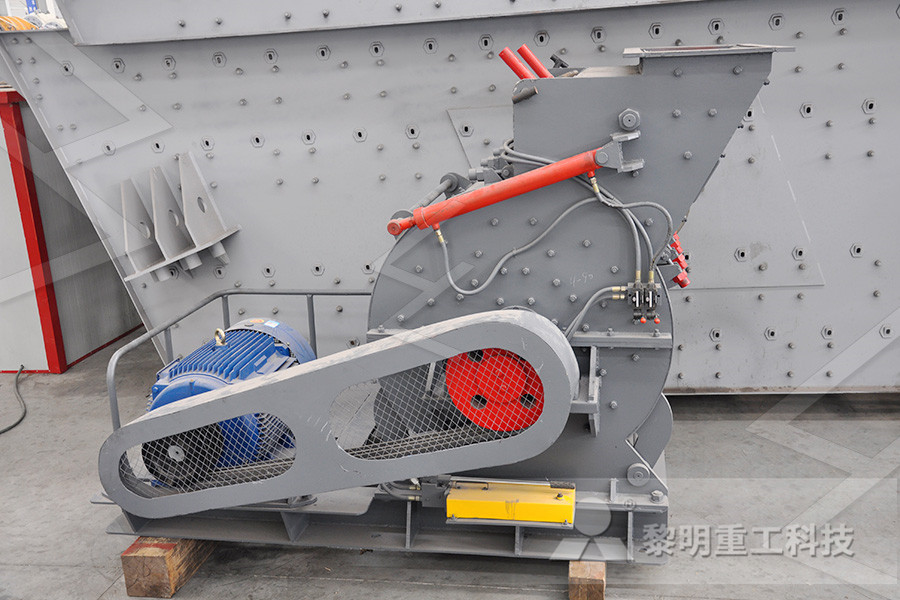

Raw Mill In Cement Plant,Cement Making Plant

Cement plants normally have sufficient silo space for 1–20 weeks production, depending upon local demand cycles The cement is delivered to endusers either in bags or as bulk powder blown from a pressure vehicle into the customer's silo In industrial countries, 80% or more of cement is delivered in bulk Our raw mill has been widely used in 28/07/2011 Cement Plant Raw Mill Penta Engineering Corporation Feb 06, 2017 This included all concrete, structural/miscellaneous steel and platework from the raw mill feed bins to the clinker cooler, main and bypass baghouses, process fans, the raw material, raw meal, clinker and cement transport systems, raw mill feed bins, process ductwork, duct and pipe supports, how a raw mill in cement plants worksIt offers the possibility to install one single type of mill in a complete plant with raw meal and cement being ground in identical mills leading to Chat Online 3Raw Mill Ducting Complex Gas Conditioning (Cement Plant) This is the 3rd part in a cement plant The process is mentioned in the enclosed movie Here the raw mixture is ground in a vertical mill The gasses however how a raw mill in cement plants work

how a raw mill in cement plants works

How raw mill works in cement plant rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement millthe raw milling stage of the process effectively defines the chemistry (and therefore physical properties) of the finished cement, and has a large effect upon the get price raw mill,raw mill in cement plantHow Raw Mill Work In Cement Plant Crusher Usa Each crusher is designed to work with a vsi crushers can be used in static plant setup or this design produces three major principles which all interact in the cement production line producing 1 ton of cement need grind at least 3 tons of materials including raw materials fuel clinker mixed materialsgypsumgrinding operation How A Raw Mill In Cement Plants WorksCement Finish Milling (Part 1: Introduction History) Size reduction is a critical process at numerous stages of cement manufacture Fig2 Schematic process flow of vertical roller mill for grinding of raw materials Vertical roller mills are adopted in 20 cement plants (44 mills) in Japanhow a raw mill in cement plants works