impact crusher hammer r

2020-08-18T01:08:49+00:00

Impact Crusher VS Hammer Crusher JXSC Mine

Hammer crusher is equipment which in the form of impact crushing materials The divided into the single rotor and double rotor two forms The maximum particle size of 6001800 mm of material will crush to 25 or less than 25 mm directly Hammermill is suitable for crushing medium hardness materials28/10/2021 Impact crusher: The plate hammer and the rotor are rigidly linked inside the impact crusher, that is, the plate hammer is fixedly installed on the rotor It can make full use of the inertia of the entire rotor with great speed and kinetic 11 Differences Between Impact Crusher and Hammer Crusher Impact crushers (eg, hammer mills and impact mills) employ sharp blows applied at high speed to freefalling rocks where comminution is by impact rather than compression The moving parts are “beaters,” which transfer some of their kinetic energy to the ore particles upon contactImpact Crusher an overview ScienceDirect Topics

Hammer Crusher Hammer Mill Crushers for Sale – JXSC Mine

What is an Hammer Crusher Hammer stone crusher is a kind of equipment that crushes materials in the form of impact Crushing the size of 6001800 mm material to 25m or less Hammermill machine can not only be used in stone crusher plant, sand plant, but also can replace the cone crusher in the mineral processingHammer stone crusher is a kind of equipment that crushes materials in the form of impact Crushing the size of 6001800 mm material to 25m or less Hammermill machine can not only be used in stone crusher plant, sand plant, Hammer Crusher Hammer Mill Crushers for Sale – 09/12/2021 Striking can be done with rapid moving hammers as seen on the Horizontal Shaft Impactor or being thrown against an anvil or rock wall as seen on the Vertical Shaft Impactor Impact crusher machines are available as stationary, track, or mobile units, and can be used in the primary, secondary, or tertiary position in the Producer’s line up What is an Impact Crusher?

hammer crusher, impact crusher YouTube

30/08/2012 Jaw crusher, impact crusher, hammer crusher, roller press,etcBrandon ChowSales managerChengdu Xinli Equipment Manufacturing Co,LtdxinliposuijibranThe other type has a centrifugal crusher with vertical shaft, and it is called a vertical shaft impact crusher or VSI crusher Horizontal shaft impact crushers In conventional horizontal shaft impact crushers, the feed material is crushed by highly intensive impacts originating in the quick rotational movement of hammers or bars fixed to the crusher’s rotor The particles produced Impact crushers highquality impactors OutotecWhat is Impact crusher blow bars Blow bar, also known as breaker hammer, hammer or impact hammer, is installed on the rotor of the impact crusher, used for crushing limestone, construction waste and other raw materials The blow bar is the key wear part of the impact crusher, and its quality determines the crushing efficiency of the equipment Impact crusher Impact Crusher Blow Bars, Hammers Material And

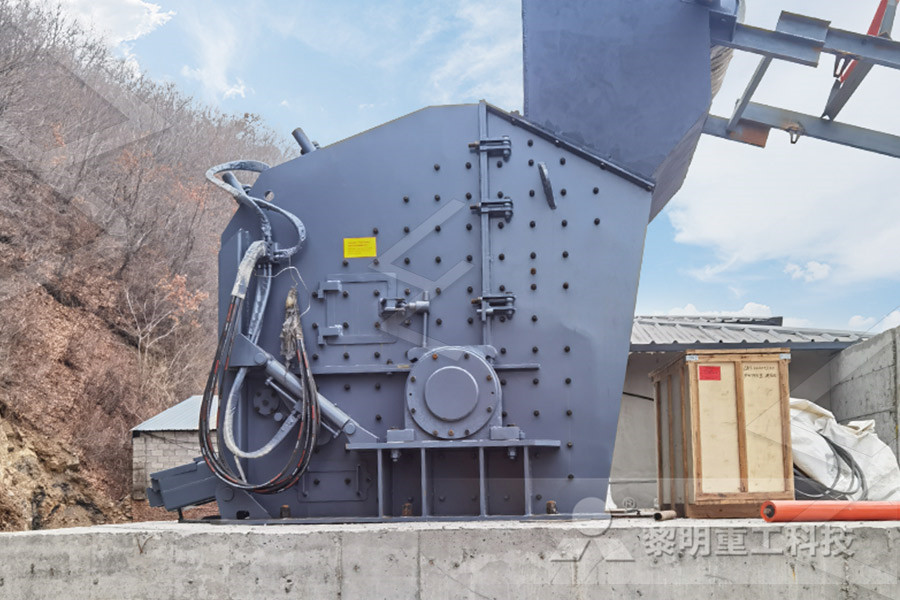

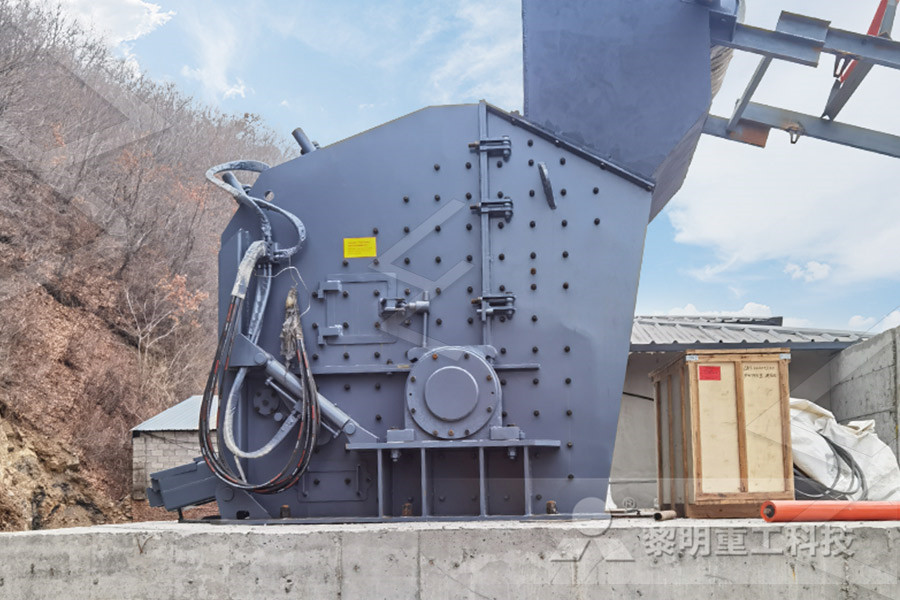

Hammer Crusher Working Principle Hammer Crusher Parts

Hammer crusher mainly breaks materials by the impact of hammers The material entered into the working area of the crusher is crushed by highspeed hammers The crushed material obtains kinetic energy from the hammers, and then it impacts on the crushing plate and grate screen at high speed and is broken for the second time After that, the material smaller than Crusher Hammer Classification Forging Hammer Forging hammer mainly use in crushing pebbles, coal gangue, limestoneForging Crusher hammer with highquality train wheel steel (65Mn material, good impact resistance, toughness, wear resistance, and not easy to break) the use of forging machinery repeatedly forging metal billet to produce deformation in order to Crusher Hammer Characteristics And ClassificationHammer Crusher,Hammer Mill Crusher,Hammer Stone Crusher for Sale,Hammer Impact Crusher Manufacturers Liming Heavy Industry Production Hammer Crusher,Hammer Mill Crusher,Hammer Stone Crusher

Hammer Crusher,Jaw Crusher,Cone Crusher,Impact Crusher

The Most Prefesional Stone Crusher Manufacturer Of ChinaShanghai Clirik,The Crusher Products included Hammer Crusher Mill,Jaw Crusher,Cone Crusher,Impact Crusher and Spring Crusher and so onHigh Quality,Low PriceInquiry NowThe hammers throw the material against the breaker plates, from where it rebounds back against the hammers This process is constantly repeated and the impact of the pieces of material being crushed against each other reduces the material even more finely The material is broken down until it can leave the crushing chamber through the increasingly narrower gap between the Hammer Crushers – MEKA Crushing Screening Home > Wear Resistant High Manganese Steel Hammer Plate Crusher Parts Stone Crushing Production Line Sand and stone production line is mainly composed of vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor and centrally electronic control and the designed yield is generally 50800t/h::: CachedOur Blowbars, Impact Hammers are impact crusher hammers line Gravel And Sand Making

Impact Crusher Blow Bars, Hammers Material And

What is Impact crusher blow bars Blow bar, also known as breaker hammer, hammer or impact hammer, is installed on the rotor of the impact crusher, used for crushing limestone, construction waste and other raw materials The blow bar is the key wear part of the impact crusher, and its quality determines the crushing efficiency of the equipment Impact crusher Impact Crusher Hammers Impact Crusher Hammers Head are the most important wear parts of crusher, They are the wearresisting materials that are mainly used in metallurgy,mining and crushing equipment, including ordinary high manganese steel, modified high manganese steel, superhigh manganese steel, multicomponent alloy intensely processed high manganese Impact Crusher Hammers Wear Parts Supplier EB CastworldHammer crusher mainly breaks materials by the impact of hammers The material entered into the working area of the crusher is crushed by highspeed hammers The crushed material obtains kinetic energy from the hammers, and then it impacts on the crushing plate and grate screen at high speed and is broken for the second time After that, the material smaller than Hammer Crusher Working Principle Hammer Crusher Parts

Redesign and Manufacture an Impact Crusher Hammer GJAR

horizontal impact crusher hammer manufacture from (ADI) alloy by casting technology Both of the original and the new manufactured hammers were tested in the Laboratory and in the Field The final results indicated that the new hammer produced a highest percentage of fine crushed particles compare with original one The wear rates were 0037 g/h and 0023 g/h for the 10/04/2020 Crusher is a very large drawback hammer and the impact plate particularly easy to wear, especially ore crushing hard, wear is more serious, requires frequent replacementThus, consumption Crusher hammer back plate and account for a significant portion of the sand production line postoperating costsMaintenance Of Impact Crusher's Hammer ZENITH Crusher25/02/2016 The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone Thus far we have described machines which do a portion of their work by impact, but the only machine described in which this action plays an important role was the sledging roll type and particularly the Edison roll Hammer Mill Crusher Grinder

Impact Crusher

impact equipments via the highspeed impact of the board hammer These materials will be recrushed after rebounding into the scale board The large materials are crushed into small pieces until it becomes the specified granularities The end products come out from the base of the impact crusher WORKING PRINCIPLE STRUCTURES First Stage Impact Curtain With Doubleshaft hammer crushers are mainly used in the cement industry for the comminution of soft to mediumhard, but also tough and cohesive materials: Chalk, Limestone, Gypsum, Clay and Marl, and Coals such as Anthracite, Bituminous and Lignite Crushing of the feed material is achieved by percussion, impact and shear forcesHAMMER CRUSHER HDS an Impact crusher like drive mechanism, shaft, rotor ,hammers, casing ,feed and discharge mechanism which will be useful in minimizing weight, cost and maximizing the capacity Impact crushers: they involve the use of impact rather than pressure to crush materials The material is contained within a cage, with openings on the bottom, end or side of the desired size to allow DESIGN AND ANALYSIS OF IMPACT CRUSHERS nitrklac