raw material for cement clinker r

2023-07-02T10:07:30+00:00

CEMENT RAW MATERIALS International Cement Review

The quality of cement clinker is directly related to the chemistry of the raw materials used Around 80–90% of raw material for the kiln feed is limestone Clayey raw material accounts for between 10–15%, although the precise amounts will vary Magnesium carbonate, which may be present in limestone, is the main undesirable impurityIf you happen to be a geologist, the raw materials quarry is probably the most interesting part of a cement works, maybe unless you view the clinkering process as igneous rocks in the making The most common raw rock types used in cement production are: Limestone (supplies the bulk of Raw materials Understanding CementClinker is a nodular material produced in the kilning stage during the production of cement and is used as the binder in many cement products The lumps or nodules of clinker are usually of diameter 325 mm and dark grey in color It is produced by heating limestone and clay to the point of liquefaction at about 1400°C1500°C in the rotary kilnWhat is Cement Clinker? Composition, Types Uses Civil

Clinker quality depends on raw material composition

14/01/2014 Portland cement manufacturing begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement kiln In this process, the chemical bonds of the raw materials are broken down and then are recombined into new compoundsTechnically, a cement producer can have almost complete control over clinker composition by blending raw materials of different compositions to produce the desired result In practice, however, clinker composition is largely determined Raw materials Understanding CementClinker is a nodular material produced in the kilning stage during the production of cement and is used as the binder in many cement products The lumps or nodules of clinker are usually of diameter 325 mm and dark grey in color It is produced by heating limestone and clay to the point of liquefaction at about 1400°C1500°C in the rotary kiln What is Cement Clinker? Composition, Types Uses Civil

Clinker quality depends on raw material composition

14/01/2014 Portland cement manufacturing begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement kiln In this process, the chemical bonds of the raw materials are broken down and then are recombined into new compounds The Clinker quality depends on raw material composition The powdered cement is then mixed with water and aggregates to form concrete that is used in construction Clinker quality depends on raw material composition If the raw materials are inappropriate, or if they are blended improperly, buildings and roads made from the concrete will have poor cement raw material and clinker cement raw05/06/2018 12 sludge waste as raw materials into the cement clinker production The burnability and the 13 structural analysis of the produced clinker were studied The results showed that the addition of 14 petroleum sludge into the clinker matrices improved the burnability of the clinker by lowering the 15 free lime content Moreover, 25% and 5% of this waste was PETROLEUM SLUDGE AS RAW MATERIAL FOR CEMENT CLINKER

Raw material mix for producing portland cement clinker

SUA1 chemical patent summarySustainable Clinker and Cement Production by Using Alternative Fuels and Raw Materials Our expertise Back Share: According to the International Energy Agency, the hightemperature process used in the manufacturing of cement accounts for around eight percent of the world’s anthropogenic carbon dioxide emissions The process also consumes up to three percent of Sustainable Clinker and Cement Production by Using 07/02/2019 The higher grinding coefficient, the more grinding of this material The grinding factors for base raw materials in cement production are given in table below Grind material : Grinding coefficient: Rotary kiln clinker: 100: Shaft furnace clinker: 115125: Granulated blastfurnace slag: 055110: Chalk: 370: Clay: 300350: Marl: 140: Limestone: 120: Quartz RAW MATERIALS IN CEMENT PRODUCTION

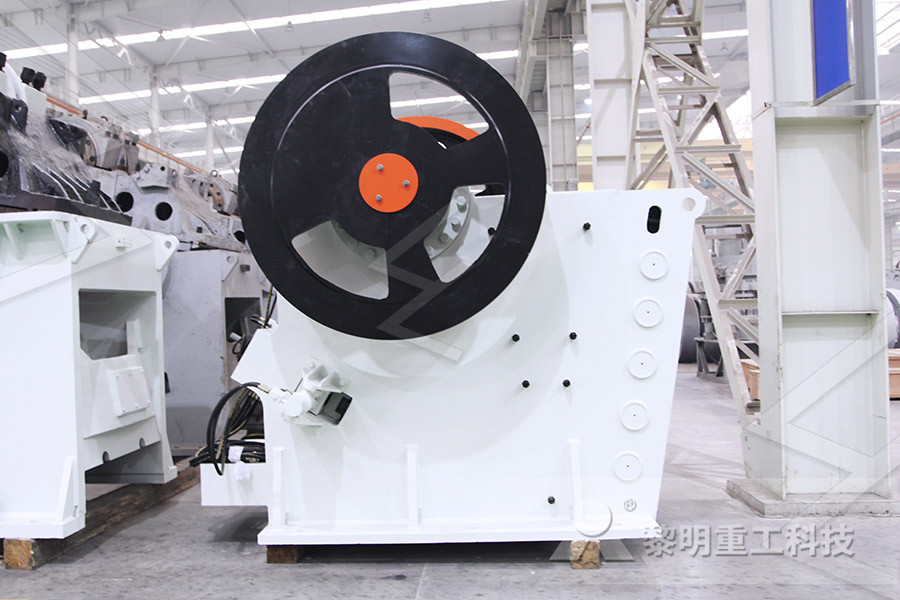

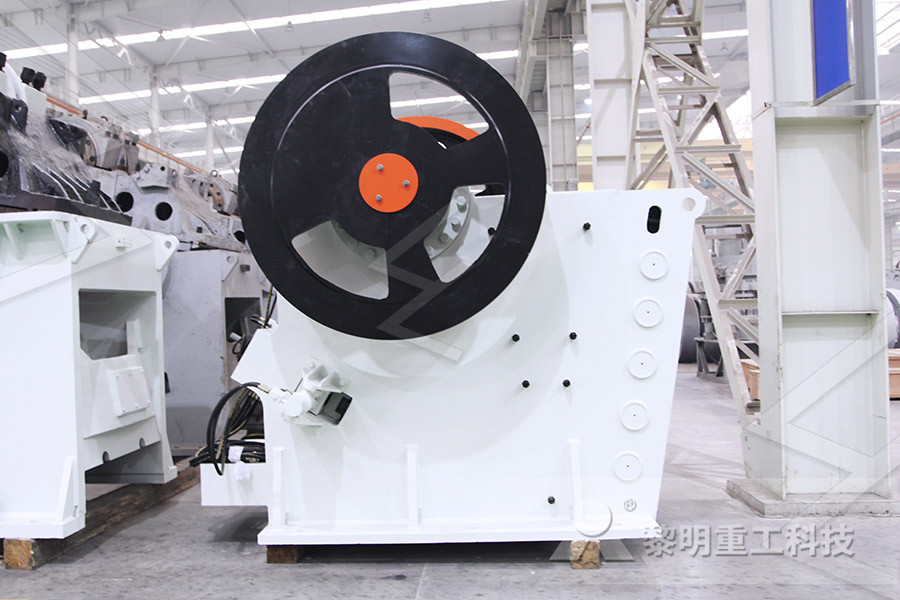

Preparation Of Cement Raw Material Cement Mill, Cement

The raw material production of cement plant can be classified into four steps: crushing, grinding, mixing and homogenizing Crushing: the limestone and other materials are crushed into small pieces by cement crusher, such as hammer crusher, cone crusher, jaw crusher, impact crusher, etc Mixing: according to the requirement of clinker, compound The cement clinker in these studies contained a small amount of CS, ranging from 03% to 25%, and possibly in combination with other waste materials such as ashes from sewage sludge, municipal incineration and coal combustion, sewage dry powder and aluminium dross that together amounted to around 8–40% of the total raw feed composition, as provided in Table 82Cement Clinker an overview ScienceDirect TopicsThe dry process of cement manufacturing means that after raw materials with different particle sizes are dried, broken and ground into powders of certain fineness, they will be sent into the dry process kiln for calcining, finally forming clinker Besides, the raw material powder can also be made into raw material balls by adding a proper raw material required for clinker in cement plant

raw materials in make clinker uf1fr

Portland pozzolana cement shall be manufactured by mixing and intergrinding Portland cement clinker, pozzolanic materials, and gypsum The manufacturing process is approximately the same as ordinary Portland cement, which can be divided into four processes: raw material crushing, raw material grinding, clinker calcination, and cement grinding05/06/2018 PDF The objective of this study is to investigate the performance of incorporating petroleum sludge waste as raw materials into the cement clinker (PDF) Petroleum Sludge as Raw Material for Cement Clinker 28/04/2021 Cement clinker raw mixtures of the targeted phase composition 65 wt% of C 2 S, 20 wt% of C 4 A 3 S and 10 wt% of C 4 AF were prepared according to generalized Bogue calculation for sulfoaluminate cements based on fly ash Each clinker raw mixture (KFA01, KFA02, KFA03) besides selected fly ash sample contained also limestone, white Fly ash as a raw material for lowcarbon cement clinkers

What raw materials are used for cement production

The main raw materials for the production of Portland cement clinker are calcareous raw materials and clay raw materials Calcareous raw material Raw materials containing calcium carbonate as the main component are all calcareous raw materials It can be divided into natural calcareous raw materials and artificial calcareous raw materials Commonly used in cement Cement raw materials require careful monitoring and control to ensure process efficiency, optimal kiln operation and clinker quality Variations in raw material quality, and improperly blended materials, adversely affect the process from raw material for cement clinker emergencedeveloppementfrSustainable Clinker and Cement Production by Using Alternative Fuels and Raw Materials Our expertise Back Share: According to the International Energy Agency, the hightemperature process used in the manufacturing of cement accounts for around eight percent of the world’s anthropogenic carbon dioxide emissions The process also consumes up to three percent of Sustainable Clinker and Cement Production by Using

USA1 Mixture of raw materials for the

A main component of cement is cement clinker, which is produced from a mixture of raw materials containing calcium oxide, silicon dioxide, aluminium oxide and iron oxide by means of mixing, grinding and burning According to the invention, the mixture of raw materials consists of a calcareous component and converter slag, the converter slag being added in a proportion of Raw Materials The quality of cement mainly depends on its raw materials (Clinker, Gypsum others) quality To produce Anchor Cement we import highquality raw materials from Thailand, Indonesia, Vietnam, China and Japan regularly The quality of raw materials has to confirm by pre shipment inspection by SGS before import All imported raw Raw Materials – Olympic cement Limited10/11/2010 Re: clinker factor The majority of Portland cement clinker manufactured around the world has a lime saturation of between 90 and 100% This means that c155 tonnes of raw mix are required and c055 tonnes of CO2 are lost due to calcination of the CaCO3 in the raw material The clinker factor is therefore 065 x the amount of raw mixclinker factor Page 1 of 2 International Cement Review