Clinker Grinding Clinker

2022-12-14T09:12:25+00:00

CLINKER GRINDING IN CEMENT PRODUCTION

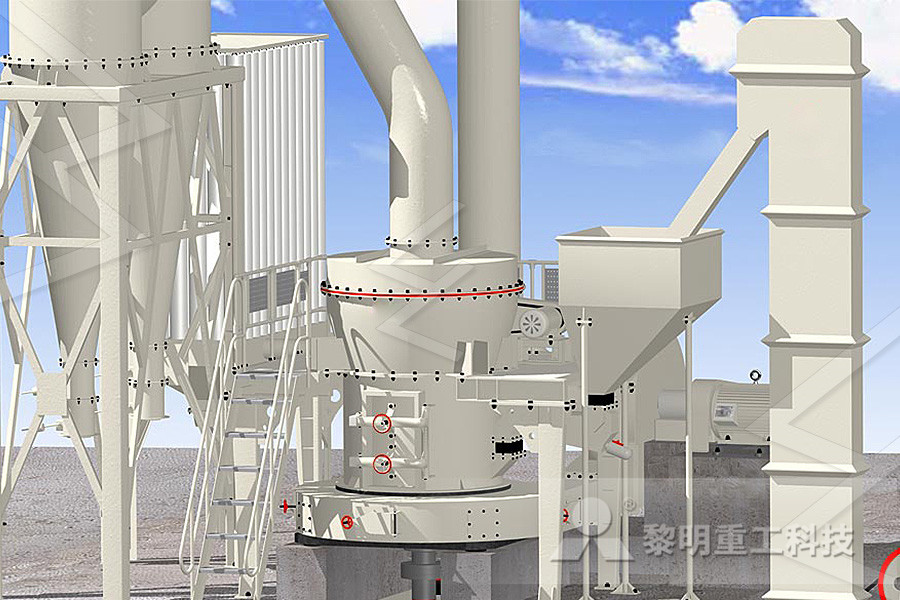

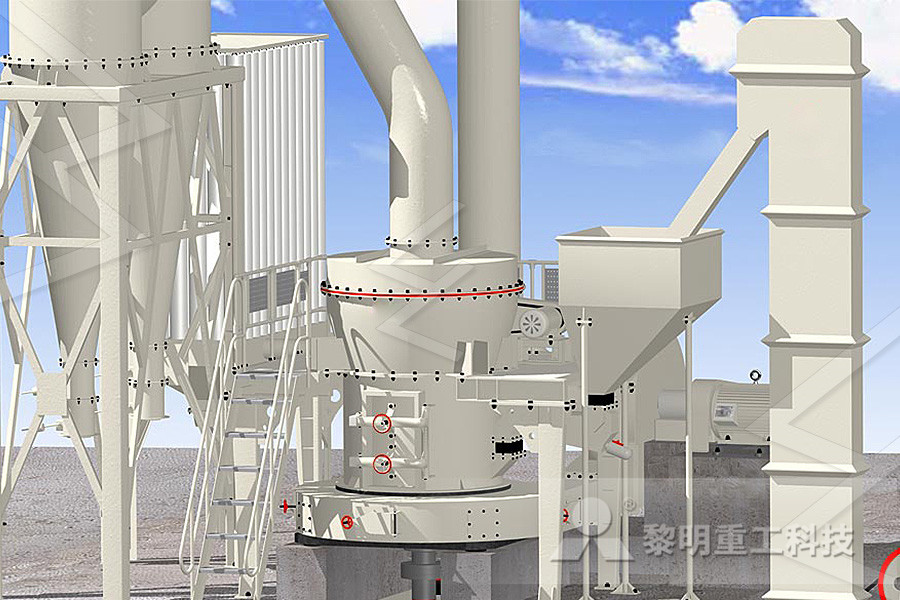

Clinker grindability is determined by quantity of electricity consumed for grinding (kW / ton) under other equal conditions In cement production Clinker Grinding Clinker and gypsum, being mixed together in predetermined proportions, are fed to the grinding mills Chemical gypsum, if used instead of natural gypsum, needs to be dried either by natural sun drying or by mechanical drying, before it is used with cooled and dried clinker for inter grinding in millsCLINKER GRINDING UNIT PROCESS UNDERSTANDING Clinker Grinding Process 1Clinker Grinding System Various materials are quantitatively given in the cement batching process according to the set ratio After the materials are discharged proportionally by the feeding metering equipment, they are sent to the ball mill by belt conveyor 2Powder Separation SystemClinker grinding unit CHAENG

Clinker Grinding Unit Great Wall

Therefore, Clinker Grinding Unit system has simple technology, low failure rate, high operation efficiency, compact allocation, construction area of 70% of ball mill, construction space of 5060% of ball mill, and it can help grinding seeks to reduce materials from roughly one meter cubes of blasted stone to a size where at least 80 percent of the raw material is less than 75 microns Finish grinding of clinker and other cement ingredients reduces 25 mm clinker balls to particle sizes optimally ranging from 3 to 30 microns TheBreakthrough in Clinker Grinding Concrete Clinker size and cement grinding Clinker size is important for the optimization of cement grinding, and is also an indicator of cement quality Having a high percentage of coarse clinker can be difficult to grind However, having a high percentage of fine clinker can also be hard to grind and have a negative impact on cement performanceClinker size and cement grinding GCP Applied Technologies

Method for grinding cement clinker Cement Lime Gypsum

(57) method of grinding cement clinkers comprising at least two kinds of clinker phases with differing grindability, comprising the steps: – feeding the cement clinker (100) to a first milling stage – grinding the cement clinker (100) in the first milling stage with a setting of grinding power and grinding time that allows grinding an easier to In the manufacture of Cement, clinker formed by sintering or fusing without melting to the point of liquefaction, aluminasilicate materials such as clay and limestone during the cement kiln stage and happens as 3 millimeters (012 inches) to 25 millimeters (098 inches) in diameter Clinker History Traditional manufacturingWhat is Clinker? (Meaning, History, Manufacturing Clinker grinding represents the most energetically demanding part of the production process and grinding stabilizers (very often known as “grinding activators”, “milling aids” or “grinding adds”, etc) play a significant part in itEfficiency of grinding stabilizers in cement clinker

Effect of chemical composition of clinker on grinding

Clinker grind were found to help grinding [5,6] Besides the chemical and ability is the measure of the ability of a clinker to resist mineralogical compositions Clinker grinding is the stage in which the final product stage in cement production ,it is independent of each other In this stage, the cement clinker is added with an appropriate amount of the mixed material ,it is be ground to Clinker Grinding Unit Great Wall Clinker size is important for the optimization of cement grinding, and is also an indicator of cement quality Having a high percentage of coarse clinker can be difficult to grind However, having a high percentage of fine clinker can also be hard to grind and have a negative impact on cement performanceClinker size and cement grinding GCP Applied Technologies

Clinker Grinding Unit, Clinkerisation Plant, Clinker

Clinker Grinding Unit Clinker Grinding Unit at Best Price Clinker Grinding Unit, clinker grinding mill India Technomart is a proud manufacturer, exporter, and supplier of highest grade ribbon blender that can be used for a variety of mixing purposes As the name suggests, these ribbon blenders have a long and complex double helical ribbon agitator fixed within a horizontal U There is much potential in optimising conventional cement clinker grinding circuits, and in the last decades significant progress has been achieved In the present paper we propose a new empirical (PDF) CONVENTIONAL CLINKER GRINDING A NEW Clinker size is important for the optimization of cement grinding, and is also an indicator of cement quality Having a high percentage of coarse clinker can be difficult to grind However, having a high percentage of fine clinker can also be hard to grind and have a negative impact on cement performanceClinker size and cement grinding GCP Applied Technologies

What is Clinker? The Importance of Clinker in Cement

The condition of grinding is not the only criteria for the formation of this microstructure The speed factor, the type and model of the furnace used are also effective in the heating and cooling process What Are The Materials Used In Clinker Manufacture? While producing clinker, there are many main components in the production phaseBoral Clinker Grinding Facility Construction is underway on Boral Cement’s $130 million new clinker grinding and cement facility at GeelongPort Construction works commenced in 2019 to build a new grinding, storage and dispatch facility Wharf side works will include hoppers and a conveying system linked directly to the facility The new Boral Clinker Grinding Facility GeelongPort Clinker is a nodular material produced in the kilning stage during the production of cement and is used as the binder in many cement products The lumps or nodules of clinker are usually of diameter 325 mm and dark grey in color It is produced by heating limestone and clay to the point of liquefaction at about 1400°C1500°C in the rotary kiln What is Cement Clinker? Composition, Types Uses Civil

Clinker Grinding Plant Layout 200 Tpd Portland Cement

Clinker Grinding Plant Layout 200 Tpd Portland Cement Clinker 17 4grinding system ball mill is the earliest grinding equipment used in cement production industry and it still plays a leading role although its efficiency is very low for example the power consumption of single particle is only 6 9 the maintenance of ball mill is simple and reliable especially for cement Clinker grind were found to help grinding [5,6] Besides the chemical and ability is the measure of the ability of a clinker to resist mineralogical compositions of the clinkers, microstructure, grinding forces It is used to estimate the energy Effect of chemical composition of clinker on Cement clinker grinding plant (Clinker Grinding Station) acts as an individual production line in the last period of the cement production process In the finished product period, the cement clinker is ground by adding moderate mixing materials and then transforms to the finished cement (cement Portland) 1Clinker Grinding Plant inczk

Clinker size and cement grinding GCP Applied Technologies

Clinker size is important for the optimization of cement grinding, and is also an indicator of cement quality Having a high percentage of coarse clinker can be difficult to grind However, having a high percentage of fine clinker can also be hard to grind and have a negative impact on cement performanceThe condition of grinding is not the only criteria for the formation of this microstructure The speed factor, the type and model of the furnace used are also effective in the heating and cooling process What Are The Materials Used In Clinker Manufacture? While producing clinker, there are many main components in the production phaseWhat is Clinker? The Importance of Clinker in Cement Clinker size is important for the optimization of cement grinding, and is also an indicator of cement quality Having a high percentage of coarse clinker can be difficult to grind However, having a high percentage of fine clinker can also be hard to grind and have a negative impact on cement performanceClinker size and cement grinding GCP Applied Technologies

Clinker Grinding Units Cement Grinding Unit

865 We are a renowned firm engaged in the provision of highly qualitative Clinker Grinding Units These units make use of raw materials such as clinker, gypsum and other additives These units are easy to install and maintain Their user Cement clinker grinding unit, or called cement grinding plant, is an individual grinding plant in the finished cement productionThe newtype cement grinding units adopt pregrinding technology The cement grinding units not only reduce the particles of feeding materials, but also help to produce cracks and flaws inside the particles, which largely increase production Cement Clinker Grinding Plant China Henan Zhengzhou IMI sells clinker to cement grinding operations in the Americas, the Caribbean, Africa, and Asia Clinker is the main ingredient used in the manufacture of Portland cement Clinker is formed in lumps or nodules, usually 325mm in diameter, by sintering limestone and aluminosilicate (clay) during the cement kiln stageClinker International Materials

Efficiency of grinding stabilizers in cement clinker

The diameter of the grinding chamber D = 200 mm was the same as its length L The mill chamber was constructed of porcelain and the grinding body stock consisted of 133 corundum balls of 251 mm diameter and 11,500 steel beads of 49 mm diameterThe grinding stock formulation arose as a result of many years development of ultrafine cement clinker milling The clinker factor and grinding energy were found to be simultaneously optimized by up to 32% and 5%, respectively, through the substitution of clinker by Use of cement grinding aids to optimise clinker factor Clinker grind were found to help grinding [5,6] Besides the chemical and ability is the measure of the ability of a clinker to resist mineralogical compositions of the clinkers, microstructure, grinding forces It is used to estimate the energy Effect of chemical composition of clinker on