iron powder production plant design r

2021-12-30T00:12:00+00:00

Iron Powder Production Plant Design

Iron Powder Production Plant Design We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment And they are mainly used to crush coarse minerals like gold and copper ore, metals like steel and iron, glass, coal, iron powder production plant design ireland Iron processing use of a smelting process to turn the ore into a form from which products can be ed in this article also is a discussion of the mining of iron and of its preparation for smelting Iron Fe is a relatively dense metal with a silvery white appearance and distinctive magnetic properties It constitutes 5 percent by weight of the Earth’s iron powder production plant design ireland16/11/2020 Iron Powder Production Plant Design Plant capacities were between 10000 and 60000 tons year 1 the world installed pelletizing capacity is currently estimated to be 4807 million tonsyear 2 as shown in figure 1 china presents the largest production capacity followed by the united states and brazil the iron ore pelletizing process consists of three main steps 1Iron Powder Production Plant Design

Iron powder production plant design Manufacturer Of High

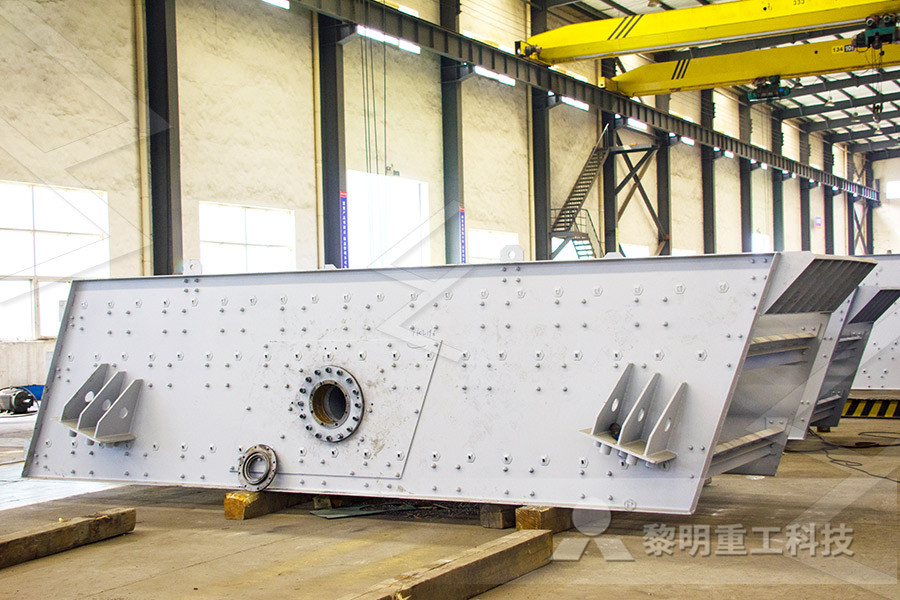

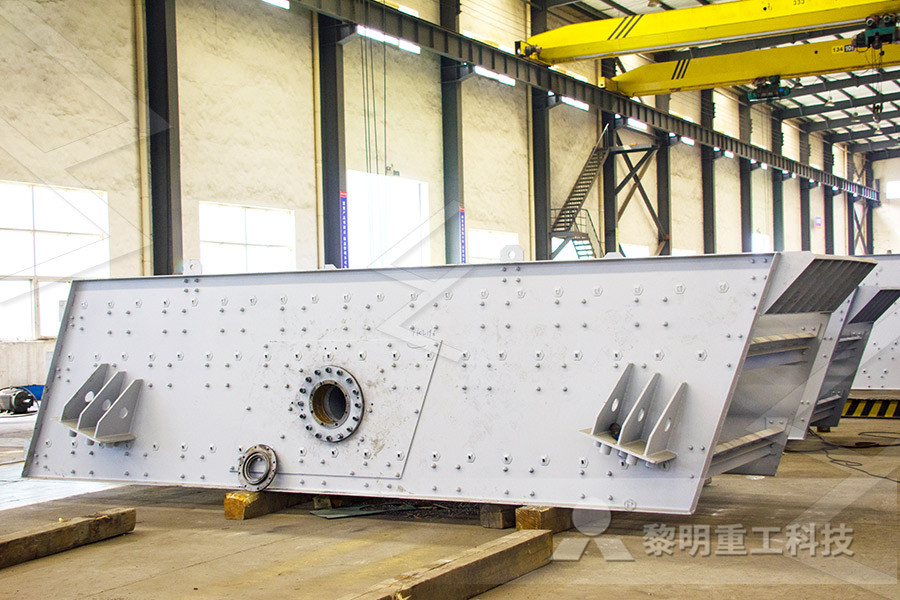

400 Plant Design Projects Mr Mogess Class room Lime Production Plant 3 Cemental Products Floor, Wall and Roof Tiles Making Plant 4 Chalk Sticks Production Plant 5 Cutstone Production Plant 6 Gypsum Powder Production Plant 7 Grinding Stone Production Plant 8 Marble Processing Plant 9 Oline Chatiron powder production plant design Home; product; iron powder production plant design; product list K Series Mobile Crushing Plant; Mobile Vibrating Screen; Belt Conveyer; Sand Washing Machine; S5X Series Vibrating Screen; GF Series Vibrating Feeder; Ball Mill; Raymond Mill; MW Series Micro Powder Mill; T130X Superfine Grinding Mill ; MTW Trapezium Mill; LM iron powder production plant design juseidonliron powder production plant design airsoftschwyz Powder Production Technologies Almost every type of iron powder can be used for the treatment of Iron chlorosis The most common types of iron powder for plants are S70,S70SQ, S100 and IRON200C Most iron powders used for plants contain about 95% or more metallic iron Sponge Iron Iron powder: a clean, Iron Powder Production Plant Design

Powder Making Production Plants ulang

Powder Making Production Plants The powder coating process is very similar to a painting process except that the paint is a dry powder rather than a liquid The powder sticks to the parts due to electrostatic charging of the powder and grounding of the parts Any substrate can be used that can tolerate the heat of curing Thermal Designs and Manufacturing Get Price Jaw SINTER PLANT Doc No: RG / 05 Rev no: 00 Effective Date: 1 OBJECTIVE Sintering is an agglomeration process of fine mineral particles into a porous mass by incipient fusion caused by heat produced by combustion within the mass itself Iron ore fines, coke breeze, limestone and dolomite along with recycled metallurgical wastes are converted into agglomerated mass at PROCESS BRIEF Ministry of Steel13/11/2020 Iron has an energy density of about 113 kWh/L, which is better than gasoline Although its specific energy is a relatively poor 14 kWh/kg, meaning that for a given amount of energy, iron powder Iron Powder Passes First Industrial Test as Renewable

Powder Detergent: Ingredients Manufacturing Process

21/06/2021 In this article, we will also break the key elements of manufacturing in a detergent powder production plant If you want to skip to that section please click this link PLC room for powder detergent production in STPP Group’s factory How do you make highquality washing powder? The best powder detergents are lightweight puffed powders with excellent free to design a plant which is able to produce hydrogen economically Though several methods of hydrogen production are there, steam reforming is the most economical means of converting fossil fuels to hydrogen at large scale especially from natural gas We discussed clearly about the operation and design of a plant for producing hydrogen from natural gas with our engineering Design of Process Plant for Producing Hydrogen from Steam Gold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient Gold Processing,Extraction,Smelting Plant Design

DAIRY PLANT DESIGN AND LAYOUT AgriMoon

Dairy Plant Design and Layout 7 Lesson 2 Importance of Dairy Plant Design 21 Introduction: Dairy Plant design, involves the estimation of capacity, process scheduling and proper layout so as to achieve the objective of handling milk at the least cost and greatest safety However, the dairy industry and the plantMilk Powder Plants Manufacturing milk powder products involves a major investment in equipment, ingredients, and resources GEA offers intelligent, robust components, equipment and endtoend solutions that help to keep your processes profitable and competitive Milk powder plants from GEA are in operation at dairy companies all over the worldPlants and equipment for processing milk powders – GEARemoval of iron and collection of iron powder from various kinds of raw materials and semifi nished products are called magnetic separation Kanetec off ers a wide variety of magnetic separators for use with lump materials, bulk materials, claylike materials and liquids A magnetic separator to select must be suitable for the purpose of use and have a sufficient capacity To MAGNETIC SEPARATORS

Iron Powder Production from Mill Scale Scrap

Iron Powder Production from Mill Scale Scrap Powdered Iron Metal Manufacturing Business Iron powder is powdered iron metal Iron powder is used in manufacturing of sintered components, soft magnetic components, brazing, iron fortification, friction products, printing, surface coating, welding, brazing, chemistry, and polymer filtrations Pure iron metal is very GKN Powder Metallurgy begins production of metal powder in China The new joint venture further expands GKN Powder Metallurgy 39 s footprint in China and makes Hoeganaes the only atomized iron powder manufacturer with The 24 600 square metre plant has been in operation since 2009 and will expand its product line to produce GKN Hoeganaes international grade atomized iron powder production line abczaamfrIron powder production In tonnage terms, the production of iron powders for PM structural part production dwarfs the production of all of the nonferrous metal powders combined Virtually all iron powders are produced by one of two processes The sponge iron process The longest established of these processes is the sponge iron process, the leading example of a Powder Production Technologies Powder Metallurgy Review

The Powder Coating Plant Process Redline Industries Ltd

The Powder Coating Plant Process Major strides have been made in the design of these machines offering major benefits to the user RED LINE offers two stateofart technology models – the RED LINE NC2NC201 and the RED LINE PPPC201PC201 POWDER COATING BOOTH WITH RECOVERY SYSTEM – in which the actual powder coating is carried out The Powder Making Production Plants The powder coating process is very similar to a painting process except that the paint is a dry powder rather than a liquid The powder sticks to the parts due to electrostatic charging of the powder and grounding of the parts Any substrate can be used that can tolerate the heat of curing Thermal Designs and Manufacturing Get Price Jaw Powder Making Production Plants ulangManufacturing Business of Pig Iron, Pig Iron Production Plant, Production of Copper Powder, Manufacturing Business ofCopper Powder, Production of Steel Rods, Manufacturing Process of Steel Bars, entrepreneurindiaco Copper Flats and Copper Tubes, Lead Battery Recycling, Steel Tube and Pipe Manufacturing Business, Stainless Steel Tube Making Plant, Non Production of Ferrous and NonFerrous Metals and Metal

Crushing Plant Design and Layout Considerations

Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals , Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimum This paper addresses the critical Höganäs is the world leading manufacturer of metal powders for powder metallurgy By utilising the endless opportunities of our metal powders we inspire industry to make more with less The applications of metal powders seem almost endless Today, our metal powders are used in areas as diverse as welding, brazing, powder metallurgy, surface coating, friction, iron, and many Metal powders Höganäs ABPlant design situations may arise due to one or more of the following: market acceptability before plants for large scale production are built Mechanical working is sometimes used to induce desired textural changes Examples include kneading and sponge mixing during the making of bread, the calendaring of pastry dough, shearing during extrusion texturization Food Processing Plant Design Layout AgriMoon

MAGNETIC SEPARATORS

Removal of iron and collection of iron powder from various kinds of raw materials and semifi nished products are called magnetic separation Kanetec off ers a wide variety of magnetic separators for use with lump materials, bulk materials, claylike materials and liquids A magnetic separator to select must be suitable for the purpose of use and have a sufficient capacity To