principle of grinding mill

2021-03-19T21:03:43+00:00

The working principle of grinding mill clirik

In cambridge dictionary, as says that a machine for crushing or cutting something into very small pieces In my words, a grinding mill crushes material between two closely placed, heavy objects like stones They are rotating with respect to one another so the material gets crushed like in a mortar and pestle The manufacturer of HGM grinding mill tells you that after the large pieces of material are broken into small particles by the crusher, they are sent to the silo by the elevator, and then the materials are evenly sent to the bulk tray on the upper part of the turntable through the feeder and the inclined guide tube onWorking principle of HGM grinding millSHANDONG Operating Principle of Grinding Mill Xinhai Grinding mill consists of a cylinder, a lining plate, a feeder, a hollow shaft, a bearing, a gearing and lubricating device, and the grinding medium—steel grinding is necessary for the grinding operation marketing@ytxinhai 0086 Language 中文РусскийEspañolFrançaisاللغة العربيةPortuguêsOperating Principle of Grinding Mill Xinhai

Grinding Mill an overview ScienceDirect Topics

The principle objective for controlling grinding mill operation is to produce a product having an acceptable and constant size distribution at optimum cost To achieve this objective an attempt is made to stabilize the operation by principally controlling the process variables Working Principle of Calcite Grinding Mill HGM series ultra fine grinding mill is mainly consist of main unit, classifier, powder collector, dust cleaner, blower, muffler, soundproof room, crusher, bucket elevator, storage hopper, and vibrating feederWorking Principle of Calcite Grinding MillWe collect together through the screw conveyor and discharge through one discharging valve Then we pack them into powders or send them into trucks for loading OK, this is the whole line working principle, and now I will introduce you to the main mill This is our main mill, as you can see, and you see the blower is here, the main machine is hereWorking Principle of YGM Grinding MillAndyIndustry

Grinding Machines: Types and Selection Principles

The rod mill uses a steel rod as the grinding medium The steel rod and the ore are in linear contact during the grinding process, which has a certain selective grinding effect The particle size of the discharged ore product is relatively uniform, The working of a grinding machine: A grinder features an electric motor that supplies motion power to the grinding wheel using pulley and belt For the portable grinder, the rotor is inside the grinding machine and the power switch is located beside the handle of a grinder So, the switch must be pressed before the grinder works Read: Working Working principle of a grinding machine Studentlesson This kind of main structure mainly has 15 parts: 1 2 Main bearing department 3 Hydraulic jacking device 4 High and low pressure pump station 5 Rotating part 6 Slow device 7 Transmission department 8 Jet lubrication device 9 Intermediate shaft 10 Discharging screen 11 Coupling 12 Air clutch 13 Synchronous motor 14The Working Principle and Structure of Rod Mill Mining

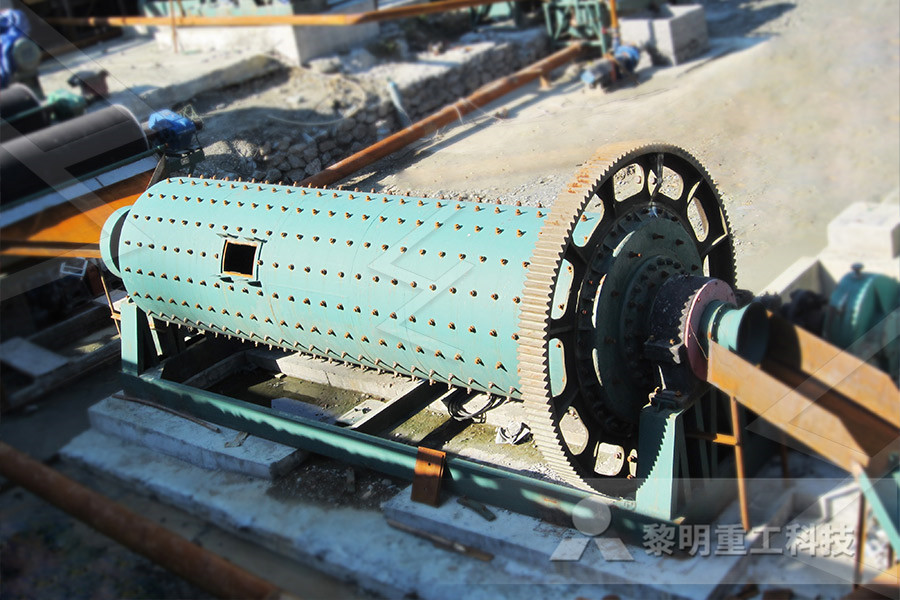

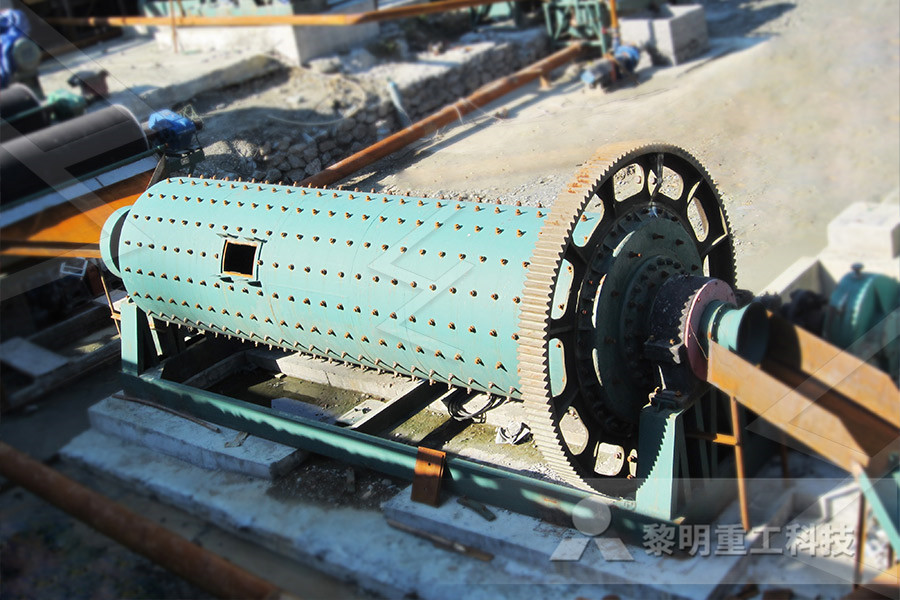

The working principle of ball mill Meetyou Carbide

The ball mill consists of a metal cylinder and a ball The working principle is that when the cylinder is rotated, the grinding body (ball) and the object to be polished (material) installed in the cylinder are rotated by the cylinder under the action of friction and centrifugal force Large steel slag ball mill can effectively reduce the cost of grinding Xinhai operates various types of ball mill, and provide you the most suitable design actual situation, the lowest operating cost beneficiation process, the most economic grinding machine which is the most suitable for ore propertiesOperating Principle of Grinding Mill Xinhai Trunnion overflow mills Airswept mills The principles of these mills are illustrated in Fig 14 and Fig 15 Batch Mill As the name implies, in the batch mills, Fig 14a, the charge of powder to be ground is loaded into the mill Grinding Mills Common Types

Grinding Machines: Types and Selection Principles

Grinding machine has been widely used in gold mines in South Africa since 1905 At that time, the grinding machine used river pebble as the grinding medium, which was essentially a gravel mill Later, in order to improve the production capacity of the mill, cast iron balls were used as the medium, so normal gravel mills were evolved into ball mills and rod millsWorking Principle of YGM Grinding MillAndy Hello everyone, This is Andy from Shanghai Clirik Machinery Co, Ltd, our factory manufactures mineral grinding mills Today I will introduce you the YGM series highpressure suspension grinding mill Raymond mill for Marble/Calcite/PetcokeWorking Principle of YGM Grinding MillAndyIndustry Grinding is the most common type of material cutting and surface generation process Mostly grinding process is used to shape and to provide better finishing parts of metals Grinding process uses one abrasive tool to BASIC PRINCIPLE OF GRINDING

Grinding mill Palamatic Process

The industrial pin mill (also known as a universal mill, turbo mill, and impact mill) is a one pass grinding equipment ideal for achieving the micronization of bulk materials and powdered products Common applications involve the fine grinding of sugar, salt, sodium bicarb, etc The average achievable particle size range of the pin mill is around a d50 of 80 microns Ball Mill Working Principle To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken to the height of a Ball Mill Working Principle And Main Parts GitHub PagesHC1700 Grinding Mill HC1700 Grinding Mill is a newly developed largescale roller mill by Guilin Hongcheng The equipment referenced the operating principle of pendulum mill and improved the swinging method Without changing other parameter, HC1700 Grinding Mill, Raymond Roller Mill, Pendulum

Rod Mills Mineral Processing Metallurgy

A Rod Mill has for Working Principle its inside filled grinding media, in this case STEEL RODS These rods run the length of the machine, which is most commonly between eight and sixteen feet in length The diameter of these Colloidal mill works on the principle of rotorstator The size reduction is affected due to shearing, when the material is passed between the narrow gap of milling surfaces of rotor and stator A rotor turns at high speeds of 3000 – Working and Principle of colloidal Mill Pharma Large steel slag ball mill can effectively reduce the cost of grinding Xinhai operates various types of ball mill, and provide you the most suitable design actual situation, the lowest operating cost beneficiation process, the most economic grinding machine which is the most suitable for ore propertiesOperating Principle of Grinding Mill Xinhai

Principles of Grinding in Ball Mills Orbis

Principles of Grinding in Ball Mills Action inside a Ball Mill drum is not a haphazard process Stirring is not random nor is the throwing of the charge There is a very specific operating speed for the most efficient grinding Working principle of HGM grinding millSHANDONG INVECH MINING TECHNOLOGY CO LIMITEDHGM grinding mill is a kind of grinding machine specialized in processing fine powder, micro powder and ultrafine powder It is commonly called threering mill, threering micropowder mill, mediumspeed mill and threering millWorking principle of HGM grinding millSHANDONG Grinding Machine Working Principle: In brief, we can say the working of the Grinding Machine is the Workpiece is fed against the rotating abrasive wheel The action of rubbing or friction generates between wok price and tool Grinding Machine: Definition, Parts, Working

Grinding mill Palamatic Process

The industrial pin mill (also known as a universal mill, turbo mill, and impact mill) is a one pass grinding equipment ideal for achieving the micronization of bulk materials and powdered products Common applications involve the fine grinding of sugar, salt, sodium bicarb, etc The average achievable particle size range of the pin mill is around a d50 of 80 micronsHC1700 Grinding Mill HC1700 Grinding Mill is a newly developed largescale roller mill by Guilin Hongcheng The equipment referenced the operating principle of pendulum mill and improved the swinging method Without changing other parameter, HC1700 Grinding Mill, Raymond Roller Mill, Pendulum Jet mills operate in compressed air, gas or high pressure superheated steam Jet mills have no moving parts, thereby eliminating contamination due to contact with external grinding media It is also an ideal Jet mill working principle Jet mill

Ball Mills an overview ScienceDirect Topics

8322 Ball mills The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter ( Figure 811) The feed can be dry, with less than 3% moisture to minimize ball Premier™ horizontal grinding mills Outotec Premier™ horizontal grinding mills are customized and optimized grinding solutions built on advanced simulation tools and unmatched expertise A Outotec Premier™ horizontal grinding mill is able to meet any projects needs, even if it means creating something novel and unseen beforeGrinding mills for mining and minerals processing Colloidal mill works on the principle of rotorstator The size reduction is affected due to shearing, when the material is passed between the narrow gap of milling surfaces of rotor and stator A rotor turns at high speeds of 3000 – Working and Principle of colloidal Mill Pharma