ball mills powered r

2022-06-30T07:06:59+00:00

ball mill wind powered sosmycosefr

ball mill wind powered New and Used Ball Mills for Sale Ball Mill Supplier New and Used Ball Mills for Sale Savona Equipment is a new and used Ball Mill supplier worldwide A ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes paints pyrotechnics ceramics and selective laser sintering read more The Tech 16/01/2020 ball mills powered; Gearless mill drives ABB Larger ball and SAG mills, with higher installed power ratings relative to the mill diameter, offer higher efficiency and throughput, roundtheclock reliability and the opportunity to mine in remote areas This makes low ore grades economical to grind ABB has delivered some of the world's largest GMDs: • 22 MW GMD for ball mills powered varletbertrandavocatfr19/06/2015 The ball mill motor power requirement calculated above as 1400 HP is the power that must be applied at the mill drive in order to grind the tonnage of feed from one size distribution The following shows how the size or select the matching mill required to draw this power is calculated from known tables ‘the old fashion way’Ball Mill Design/Power Calculation

Ball Mills Mineral Processing Metallurgy

13/02/2017 A ball mill efficiently operated performs a wide variety of services In small milling plants, where simplicity is most essential, it is not economical to use more than single stage crushing, because the SteelHead Ball or Rod Mill will take up to A ball mill is a type of grinder used to grind and blend bulk material into QDs /nanosize using different sized balls The working principle is simple; impact and attrition size reduction take place as the ball drops from near the top of a rotating hollow cylindrical shellBall Mills an overview ScienceDirect Topicsball mills powered The following equation is used to determine the power that wet grinding overflow ball mills should draw For mills larger than 33 meters 10 feet diameter inside liners the top size of the balls used affects the power drawn by the mill This is called the ball size factor S Rod and Ball Mills by CA Rowland and DM Kjos AllisChalmersball mills powered thincafricacoza

Ball Mill Application and Design Paul O Abbe

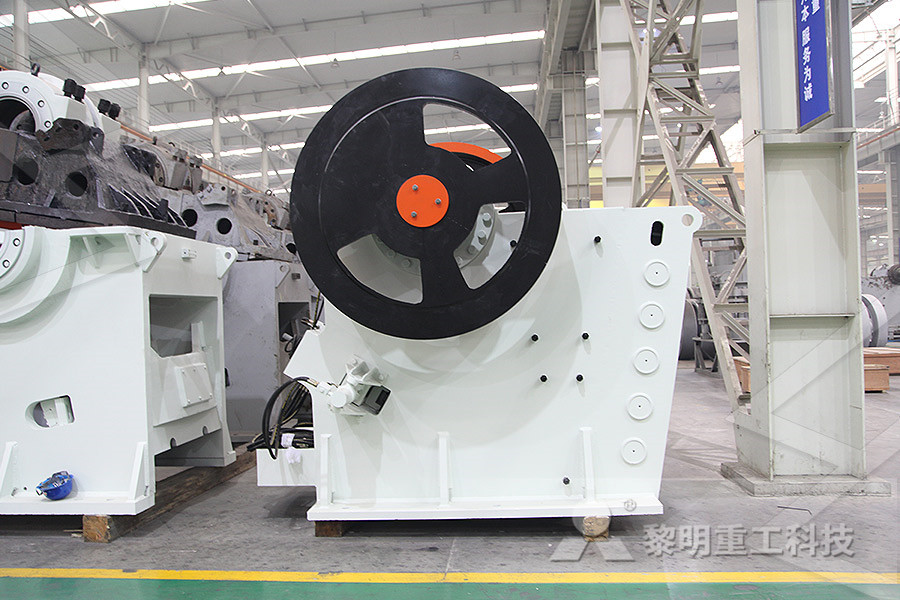

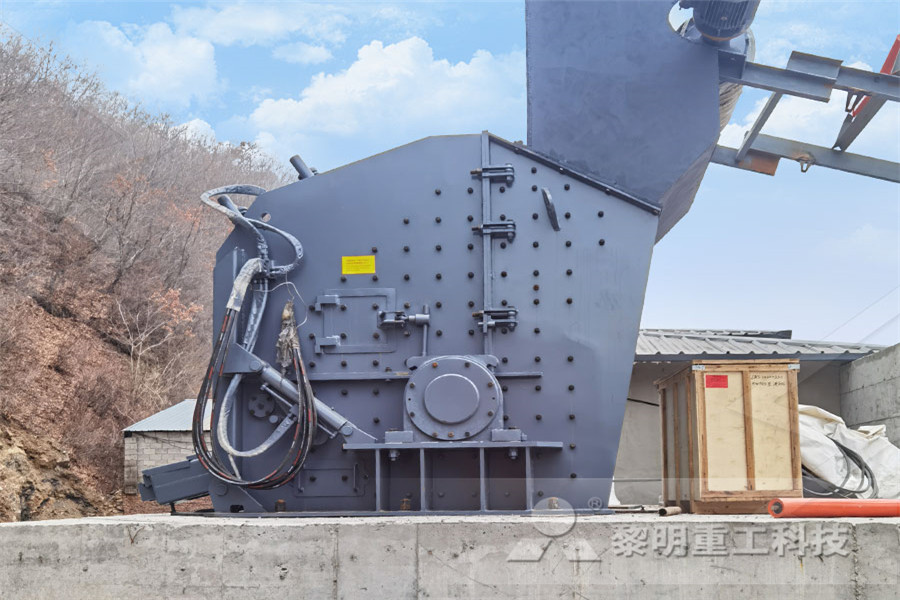

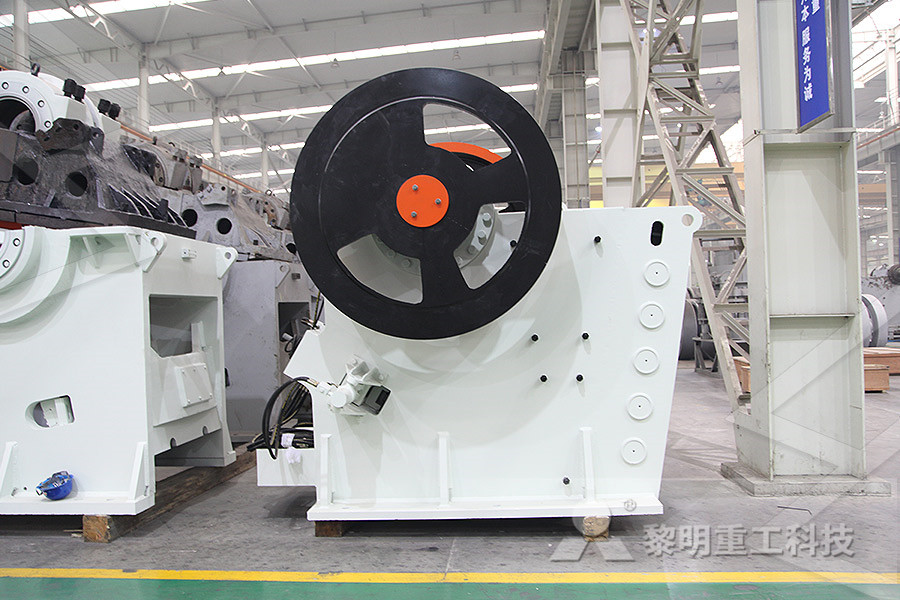

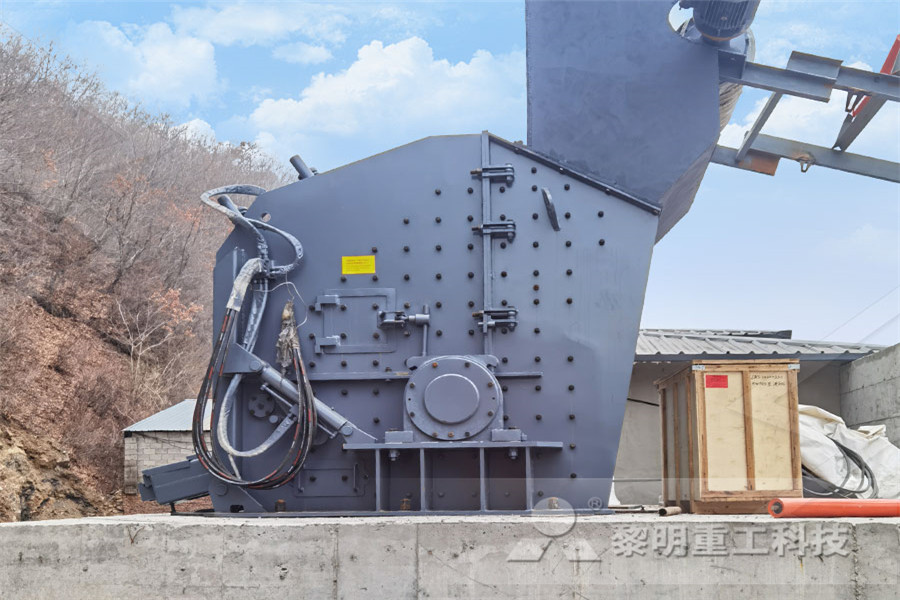

Ball mills are simple in design, consisting of horizontal slow rotating vessels half filled with grinding media of ¼” to 15” The particles to be milled are trapped between the grinding media or balls and are reduced in size by the actions of impact and attritionUNUSED 22' x 38' (6706mm x 11582mm) Ball Mill, 10,000 kW (13,410 HP) Twin Pinion 50 Hz Motors and Gear Reducers Manufacturer: Inventory ID: 6CCM02 View Details HP: 13,410: KW: 10,000: Diameter: 22 Feet (6706mm) LOT of (2) UNUSED FLSMIDTH 22' x 365' Ball Mills with Dual 4,900 kW (6,662 HP) Motor Drives Inventory ID: 6CGM02 LOT of Used Ballmills For Sale Grinding Mills, Crushers These ball mills are mainly used to grind to the material from cement plant, chemical plant, metallurgy plant, refractory material and slag material They have the advantages of low area occupying, running smoothly, easy operation, etc And Ball Mill Powered by EmpireCMS

Ball Mill Design/Power Calculation

19/06/2015 Ball Mill Power Calculation Example #1 A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch (6350 microns) The required product size 16/01/2020 ball mills powered; Gearless mill drives ABB Larger ball and SAG mills, with higher installed power ratings relative to the mill diameter, offer higher efficiency and throughput, roundtheclock reliability and the opportunity to mine in remote areas This makes low ore grades economical to grind ABB has delivered some of the world's largest GMDs: • 22 MW GMD for ball mills powered varletbertrandavocatfr13/02/2017 Ball mills can be used for coarse grinding as described for the rod mill They will, however, in that application produce more fines and tramp oversize and will in any case necessitate installation of effective classification If finer grinding is wanted two or three stage grinding is advisable as for instant primary rod mill with 75—100 mm (3″—4″) rods, secondary Ball Mills Mineral Processing Metallurgy

Introduction of ball mill prominertech

23/03/2022 Ball mill is the necessary grinding equipment for mineral processing plant It is mainly used as grinding operation before sortingThis paper introduces the structure of the ball mill, its working principle and performance characteristics Classification according to the different ways of ball millsball mill wind powered New and Used Ball Mills for Sale Ball Mill Supplier New and Used Ball Mills for Sale Savona Equipment is a new and used Ball Mill supplier worldwide A ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes paints pyrotechnics ceramics and selective laser sintering read more The Tech ball mill wind powered sosmycosefrThe High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming effects These ball mills are also suitable for mechano chemistry Mixer Mills grind and homogenize Ball Mill RETSCH powerful grinding and homogenization

Ball Mills an overview ScienceDirect Topics

Conical Ball Mills differ in mill body construction, which is composed of two cones and a short cylindrical part located between them (Fig 212) Such a ball mill body is expedient because efficiency is appreciably increased Peripheral velocity along the conical drum scales down in the direction from the cylindrical part to the discharge outlet; the helix angle of balls is decreased Ball Mills Showing all 16 results Laboratory Grinding Mill US $ 11,000 Benchtop Grinding Mill Rod/Ball US $ 7,500 Jar Mill US $ 3,000 Small Grinding / Regrinding Mill 3 to 10 Kilo/Hr Sale! Grinding Mill for Metallurgical Pilot Testing of 10 to 150 Kilo/Hr US $ 50,000 Ball Mills Best of 2022 911Metallurgist05/07/2020 Ball mills grind material by impact and attrition The degree of milling in a ball mill is influenced by; a Residence time of the material in the mill chamber b The size, density, and number of the balls c The nature of the balls (hardness of the grinding material) d Feed rate and feed level in the vessel e Rotation speed of the cylinder Several types of ball mills exist Ball Mill: Operating principles, components, Uses

Ball Mill Design/Power Calculation

19/06/2015 Ball Mill Power Calculation Example #1 A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch (6350 microns) The required product size 16/01/2020 ball mills powered; Gearless mill drives ABB Larger ball and SAG mills, with higher installed power ratings relative to the mill diameter, offer higher efficiency and throughput, roundtheclock reliability and the opportunity to mine in remote areas This makes low ore grades economical to grind ABB has delivered some of the world's largest GMDs: • 22 MW GMD for ball mills powered varletbertrandavocatfr13/02/2017 Ball mills can be used for coarse grinding as described for the rod mill They will, however, in that application produce more fines and tramp oversize and will in any case necessitate installation of effective classification If finer grinding is wanted two or three stage grinding is advisable as for instant primary rod mill with 75—100 mm (3″—4″) rods, secondary Ball Mills Mineral Processing Metallurgy

Introduction of ball mill prominertech

23/03/2022 Ball mill is the necessary grinding equipment for mineral processing plant It is mainly used as grinding operation before sortingThis paper introduces the structure of the ball mill, its working principle and performance characteristics Classification according to the different ways of ball millsball mill wind powered New and Used Ball Mills for Sale Ball Mill Supplier New and Used Ball Mills for Sale Savona Equipment is a new and used Ball Mill supplier worldwide A ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes paints pyrotechnics ceramics and selective laser sintering read more The Tech ball mill wind powered sosmycosefrThe High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming effects These ball mills are also suitable for mechano chemistry Mixer Mills grind and homogenize Ball Mill RETSCH powerful grinding and homogenization

Ball Mills an overview ScienceDirect Topics

Conical Ball Mills differ in mill body construction, which is composed of two cones and a short cylindrical part located between them (Fig 212) Such a ball mill body is expedient because efficiency is appreciably increased Peripheral velocity along the conical drum scales down in the direction from the cylindrical part to the discharge outlet; the helix angle of balls is decreased Ball Mills Showing all 16 results Laboratory Grinding Mill US $ 11,000 Benchtop Grinding Mill Rod/Ball US $ 7,500 Jar Mill US $ 3,000 Small Grinding / Regrinding Mill 3 to 10 Kilo/Hr Sale! Grinding Mill for Metallurgical Pilot Testing of 10 to 150 Kilo/Hr US $ 50,000 Ball Mills Best of 2022 911Metallurgist05/07/2020 Ball mills grind material by impact and attrition The degree of milling in a ball mill is influenced by; a Residence time of the material in the mill chamber b The size, density, and number of the balls c The nature of the balls (hardness of the grinding material) d Feed rate and feed level in the vessel e Rotation speed of the cylinder Several types of ball mills exist Ball Mill: Operating principles, components, Uses