linear vibrating screen in mineral processing and mf

2020-11-11T03:11:39+00:00

Linear Vibrating Screen xinhaiepc

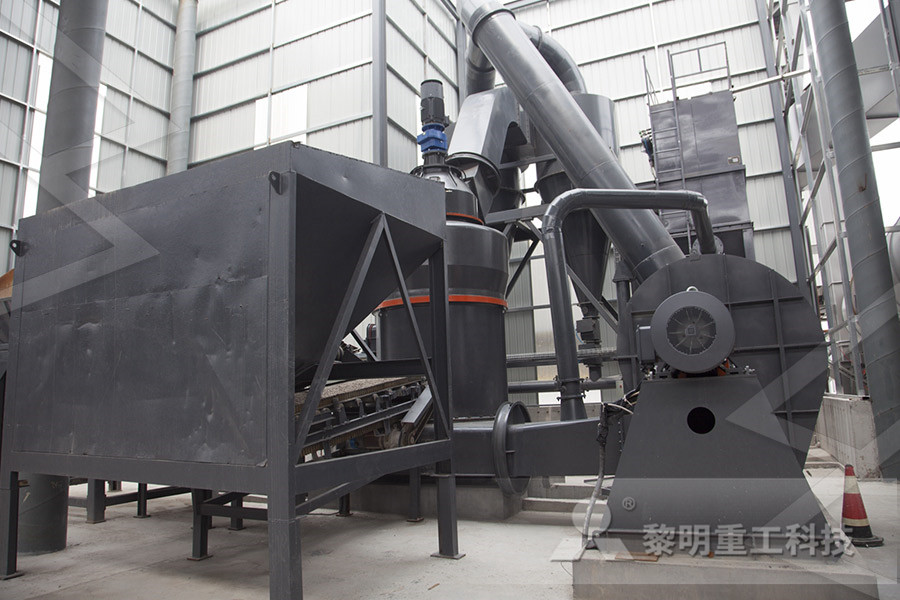

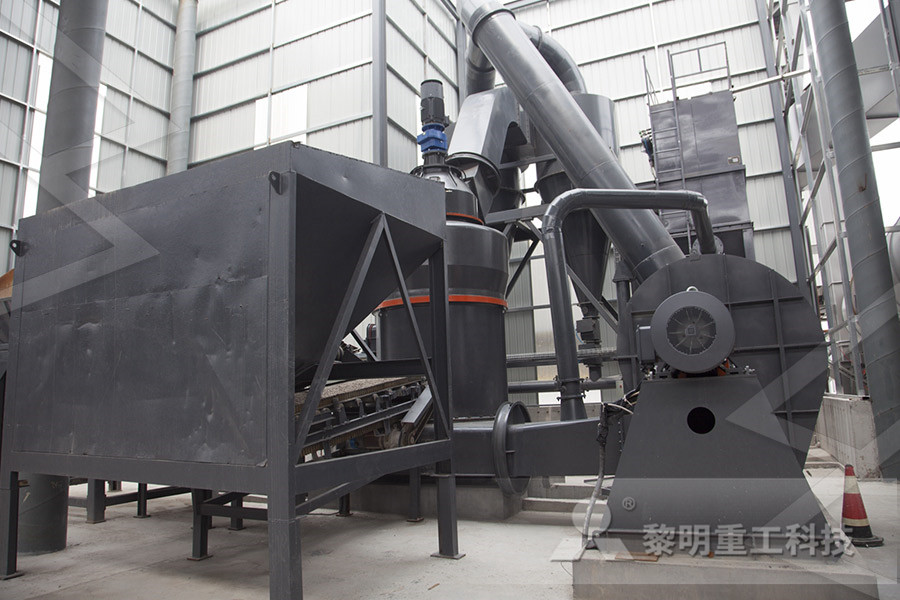

DZS linear vibrating screen is driven by double vibration motors While two vibration motors doing synchronous rotation or counter¬rotation, the exciting force generated by eccentric block is cancelled out with transverse exciting force, and the longitudinal exciting resultant force is passed on the whole screen surface, in this way, the motion track of screening machine is a straight line Outotec MF Seriestrade; banana screens are specifically suited for large material volumes with a high percentage of undersize product in the feed material They are ideal for mineral processing of all metallic and nonmetallic ores Efficient operation Thanks to the high material velocity, blinLinear vibrating screener MF™ series Corporation ZK linear vibrating screen trajectory is linear, for coal preparation, coal washing, mineral processing, power generation and other industries, On the medium and fine materials dry and wet screening, Can also be dewatering, Off medium, desliming operationsZK Linear Vibrating Screen winnermanufacturing

Circular Vibrating Screen VS Linear Mineral Processing

The circular vibrating screen is also called a singleshaft vibrating screen because the exciter is a shaft and uses an inertial motor to work The linear vibrating screen is composed of two shafts and works on the principle of vibration motor excitation, so it is also called double Shaft vibrating screen 3 Hole blocking phenomenonSchenck Process linear vibrating screens fulfil all these requirements perfectly They can handle the largest quantities of materials, and classify them to a high level of accuracy Driven by robust DF force exciters, they are specially LinaClass® SLG Linear vibrating screen Circular vibrating screen The multilayer vibrating screen is specially designed for screening stones in quarries It can also be used to classify products in coal preparation, mineral processing, building material production, power and chemical industries The main advantages of the circular vibrating screen are as followsVibrating Screen Mineral Processing

Vibrating Screens Vibramech

Vibramech Vibrating Screens Feature: Vibramech screens are equipped with vibrator motor, geared exciter or oscillator drives, and are available in single, double or tripledeck configurationThe range of screening media includes polyurethane panels, rubber panels, wedge wire panels or woven wire panelsThe ANDRITZ linear screen DLS is proven in the removal of oversize particles from process feed streams and has been found to be effective in applications such as particle classification, trash screening, water waste removal and wash Linear screen DLS ANDRITZ The MultiFlo is a free swinging, banana shaped and linear motion screen Motion is provided by revolving eccentrics imparting both separating GForce and the material travel force components The screen is design assured using Finite Element Analysis (FEA), EN19931 MF MINING SCREENS Brown Energy Group Inc

Linear vibrating ScreenGongyi Forui Machinery

The linear vibrating screens are used in many industries, such as, steel making, mining, quarrying, foundries, food processing and chemical industry for the separating of bulk materials like stone aggregates, different kind of sand, Schenck Process: Linear Vibrating Screen for Mineral Processing in Mining LinaClass 3 Schenck Process: Centrifugal Sifter Hygienic Design Sifts High Volume Kemutec KEK 4 Schenck Process: Granulation Grinding Cone Mill Machine from Kemutec for Gentle Milling 5 Schenck Process: Dense Phase Conveying Pneumatic Conveyor with ProPhase 6Schenck Process: Linear Vibrating Screen for Mineral The robust screen frame is manufactured, depending on the application, either in welded or in bolted and glued design These screens can be driven by one or several IFE exciter drives or by a pair of IFE unbalanced motors IFE linear Linear motion vibrating screen IFE

Stability analysis of the screening process of a vibrating

Abstract Deep dry screening is the key unit in mineral processing A vibrating flipflow screen (VFFS) with elastic sieve mats has been widely used for screening finegrained minerals due to its good performance The stability of the VFFŚs dynamic response largely affects its screening efficiency and processing capacity, however, it has 1 Check the anchor bolts In the precautions for the use of vibrating screen, we need to carefully check the anchor bolts This position is easy to loosen, once it is loose, it will produce great vibration and noise, even burn down the motor, which will cause great damage to the equipment 2 Check the screenThe Maintenance and Use of Vibrating Screen Mineral The ANDRITZ linear screen DLS is proven in the removal of oversize particles from process feed streams and has been found to be effective in applications such as particle classification, trash screening, water waste removal and wash Linear screen DLS ANDRITZ

Vibrating Screens Vibramech

Vibramech Vibrating Screens Feature: Vibramech screens are equipped with vibrator motor, geared exciter or oscillator drives, and are available in single, double or tripledeck configurationThe range of screening media includes polyurethane panels, rubber panels, wedge wire panels or woven wire panels Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library screeningcapacity screencapacity vibratoryscreendesignvibratingscreentypes Vibrating Screen Working Principle The MultiFlo is a free swinging, banana shaped and linear motion screen Motion is provided by revolving eccentrics imparting both separating GForce and the material travel force components The screen is design assured using Finite Element Analysis (FEA), EN19931 MF MINING SCREENS Brown Energy Group Inc

Influence of vibration mode on the screening process

The motion of a vibrating screen can be defined as three types, linear, circular or elliptical, depending upon the trajectory Fig 1 shows that λ is the amplitude and β is the vibration direction angle of the model The simulations use an improved DEM dry contact softsphere model , Fig 2 shows that k n and d n are the normal stiffness and normal damping; k t and d Sandvik IFE linear motion vibrating screens are used for screening of granulous bulk material The robust screen frame is manufactured, depending on the application, either in welded or in bolted and glued design These screens can be driven by one or several IFE exciter drives or by a pair of IFE unbalanced motors IFE linear Sandvik linear motion vibrating screen Jaw crusher China 70150tph capacity Mining Vibrating Screen Yk1865 1 Introduction vibrating sieves are used to separate materials into various sizes for further processing or for end use The material is separated by passing through a vibrating "screen or meshes" which has a number of different sized according to customer's requirementsVibrating Screen, Separator Machine Sand Linear Vibrating

Vibrating Screening Machine, Manufacturer of Vibrating

Linear Vibrating Screen Product introduction A vibrating screen that screen box takes reciprocating movement along the directional linear, is used for fine screening Capacity 20~300t/h Product improvement Screen angle is adjustable Vibrating motor as vibration exciter, low energy consumption Mineral Processing EPC and Equipment Tel Rotary vibrating screen is designed as a highprecision screening machinery It is composed of vertical motor,and eccentric weight installed at two ends Linear vibrating screen is widely used in mining, coal, refractories, metallurgy, building materials and other industriesVibrating ScreenScreening MachinesHenan Pingyuan Abstract Deep dry screening is the key unit in mineral processing A vibrating flipflow screen (VFFS) with elastic sieve mats has been widely used for screening finegrained minerals due to its good performance The stability of the VFFŚs dynamic response largely affects its screening efficiency and processing capacity, however, it has Stability analysis of the screening process of a vibrating

Xinxiang Xianchen Vibration Machinery Co, LTD

Stainless steel linear vibrating screen is a kind of screening equipment with medium and fine material with linear movement trajectory In coal preparation, mineral processing, power supply, sugar, salt, chemical, abrasive, refractory, food and other industries, it is an high efficiency screening product to do dry and wet sieving with medium The MultiFlo is a free swinging, banana shaped and linear motion screen Motion is provided by revolving eccentrics imparting both separating GForce and the material travel force components The screen is design assured using Finite Element Analysis (FEA), EN19931 MF MINING SCREENS Brown Energy Group IncVibrating screens are critical machines used for size classification in mineral processing eir proper operation, including accurate vibration movement Schematic diagram of vibrating screen and its

Washing Screening Equipment benefication

Circular Vibrating Screen The YZS circular vibrating screen is a new screening equ Hydrocyclone Hydrocyclone is mainly used in mineral processing as a c Dewatering Screen The main deck of the screen slopes upwards at The motion of a vibrating screen can be defined as three types, linear, circular or elliptical, depending upon the trajectory Fig 1 shows that λ is the amplitude and β is the vibration direction angle of the model The simulations use an improved DEM dry contact softsphere model , Fig 2 shows that k n and d n are the normal stiffness and normal damping; k t and d Influence of vibration mode on the screening process