fine particle wet sizing screen r

2020-10-07T23:10:42+00:00

Fine Particle Wet Sizing Screen

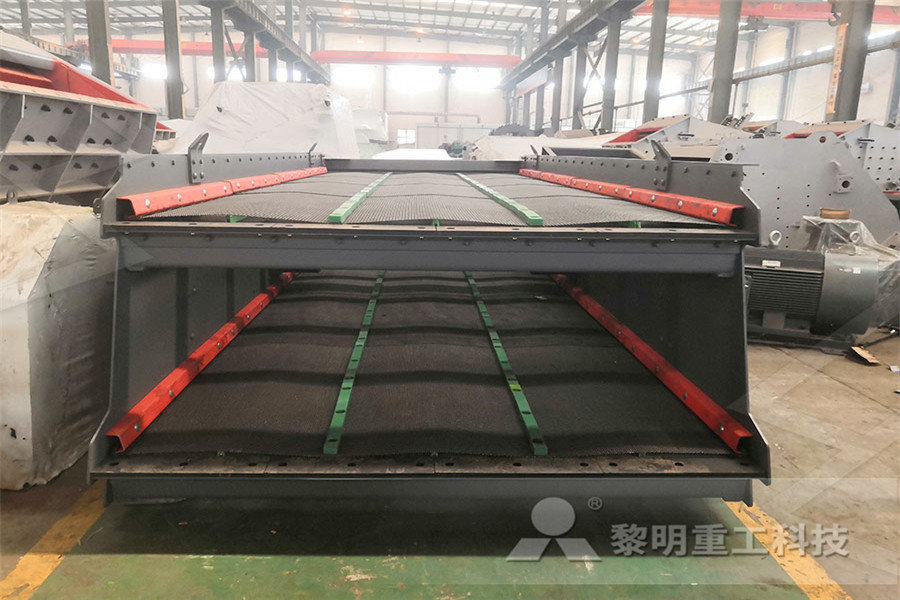

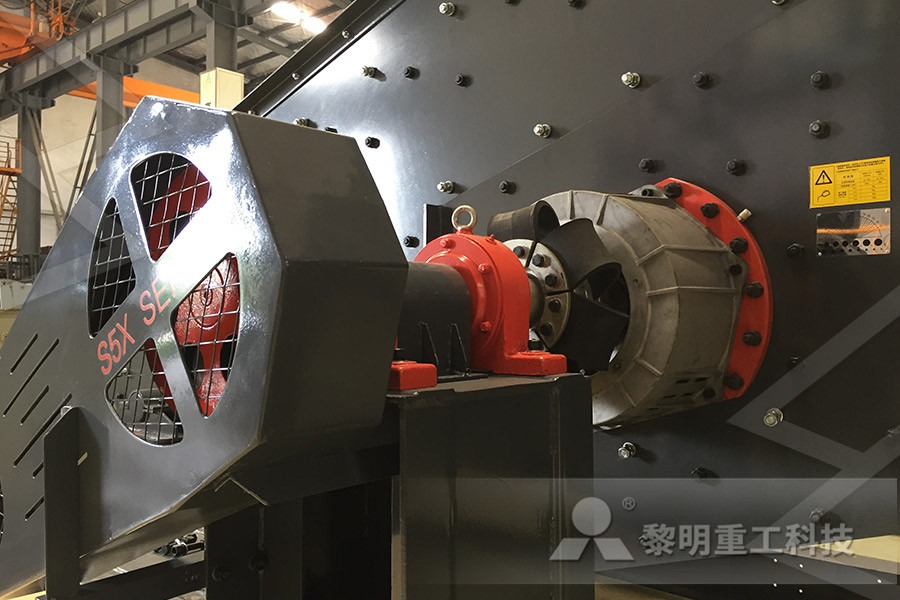

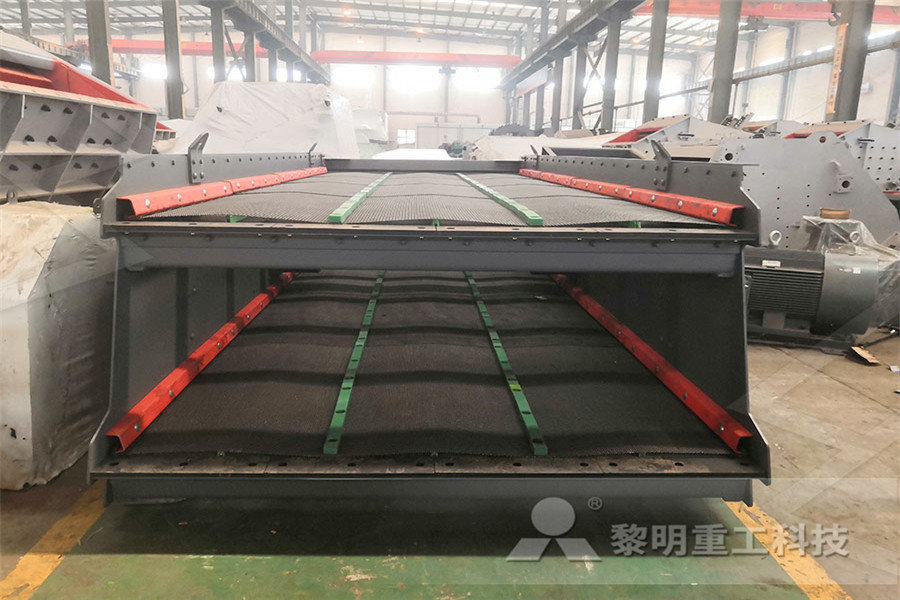

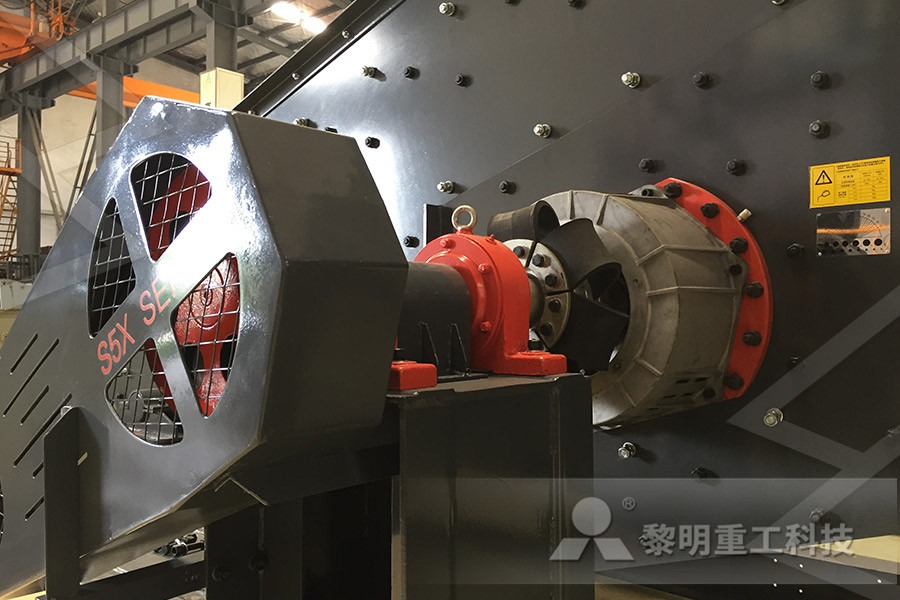

Fine Particle Wet Sizing Screen We are here for your questions anytime 24/7, welcome your consultation Get Price Highcapacity wet and dry screening using panels that are constructed from a special high temperature polyurethane material Vibratory screening equipment is cheap to screen or classify wet or dry materials like wet ash or dry frac sand into multiple grades by Fine Particle Wet Sizing Screen FOB Reference Price: Get Latest Price The high capacity stacked sizingscreening machine consists of up to five decks positioned one above the other and all operating in parallelIts use together with urethane screen surfaces as fine as 75 microns 200 mesh has made fine wet screening aFine Particle Wet Sizing ScreenThe Derrick Repulp Wet Sizing Screen is the solution for difficult to screen materials that require the oversize product fraction to meet tight quality specifications The Repulp machine’s high speed, low amplitude motion coupled with its countercurrent spray wash water system effectively removes fine particlesFINE SCREENING Derrick Corporation

(PDF) MODEL FOR FINE WET SCREENING ResearchGate

Most models do not give good predictions for wet fine screening To facilitate model development, pilot plant tests were performed using a single deck Derrick Screen at aperture sizes of 45µm,Screening is the process of separating particles by size and fine screening typically refers to separations in the range of 10 mm (3/8 inch) to 38 microns (400 mesh) Fine screening, wet or dry, is normally accomplished with high frequency, low amplitude, vibrating screening machines with either elliptical or straightline motionTaken from Recent Advances in Mineral Processing Plant Review the screen sizing formula and the effects that each of the above can have on the sizing process • Review speed, stroke and slope • Media options available to today's producers and there applications • Troubleshooting guidelines and items to review at the quarry • To prepare a sized product Screen Duties • Take home message: Final product sizing Screen Duties • Principles of Screening and Sizing

fine particle wet sizing screen gardenstatefr

fine dry screen sizing bauxite The ® Stack Sizer ® redefines fine particle wet screening, offering high capacity and exceptional efficiency in minimal space Consisting of up to five individual screen decks positioned one above the other and operating in parallel, the Stack Sizer provides a unique combination of high capacity and efficiency that sets the Stack Sizing Screen Multotec’s highquality, durable sizing screens are customised to suit your requirements, delivering a wide range of wet and dry screening solutions to all your mineral processing applications Our sizing screens optimise your feed material separation by achieving your precise cut point requirements, maximising your processing Sizing Screen MultotecA particle sizing and separating apparatus is disclosed The apparatus includes a base and a frame that is movably connected to the base A motor assembly is provided to vibrate the frame and at least two screens are connected to the frame Means also are provided for feeding particles to each screen from two opposing sides of each screen and for evenly distributing USB2 Wet fine particle sizing and separating

FINE SCREENING Derrick Corporation

efficiency, fine particle wet screening with the introduction of the challenging fine sizing problems: • Improve efficiency and capacity in closed grinding circuits • Improve final concentrate grade and recovery • Improve size classification and product quality of mineral concentrates • Reduce impurities in fine iron concentrates (eg silica, alumina) • Pumping and pipeline Wet fine particle sizing and separating apparatus United States Patent Abstract: A particle sizing and separating apparatus is disclosed The apparatus includes a base and a frame that is movably connected to the base A motor assembly is provided to vibrate the frame and at least two screens are connected to the frame Means also are provided for feeding Wet fine particle sizing and separating apparatus 01/12/2003 The aims of this study were to establish the causes of fine coal generation during wet screening as well as the effect of wet screening on particle size distribution (PSD) and chemical properties 2 Background The Sasol–Lurgi fixed bed dry bottom gasification process operates on lump sized coal The coal bed has to be porous and permeable to allow the rising Effect of wet screening on particle size distribution and

Vibrating Screen For Fine Particle tostainpaysagesfr

loose density of selected materials generally, materials with large bulk density and block particles are easy to pass through the sieve, and the screening efficiency is highFor wet fine particle size separation ranging from 1/2 inch to 100 mesh for wet sizing of specialty sand for mill discharge screen in fine grinding circuit for scalping removal of coarse materials curved deck sizing Sizing Screen Multotec’s highquality, durable sizing screens are customised to suit your requirements, delivering a wide range of wet and dry screening solutions to all your mineral processing applications Our sizing screens optimise your feed material separation by achieving your precise cut point requirements, maximising your processing Sizing Screen Multotec5 9 September 2022 Johannesburg Expo Centre Subscribe Book Your StandIntroducing the SuperStack® Wet Sizing Screen – Electra Mining

How To Perform a Wet Sieving Analysis WS Tyler

Wet Sieve analysis can be accomplished on a ROTAP Sieve Shaker using the wet sieving kit that WS Tyler offers This kit will allow you to perform a sieve analysis on a ROTAP RX29 using water You can then run your sample down through the stack of sieves using the machine like normal, with the addition of water through the added tubeWet sieving is an ideal sample preparation process for specimens with a high fraction of granular materials and enough fines content present to make sieving difficult The fines can stick together in clumps, preventing an accurate assessment by sieving Wet sieving is also useful for direct particle sizing of problem materials including:Wet Sieving: A Practical Guide Gilson CoWINNER Distribution ScreenD is a linear vibration produced by highfrequency dualvibration motors rotating in opposite directions, which makes Distribution screenDfine particle size beneficiation and

USB2 Wet fine particle sizing and separating

A particle sizing and separating apparatus is disclosed The apparatus includes a base and a frame that is movably connected to the base A motor assembly is provided to vibrate the frame and at least two screens are connected to the frame Means also are provided for feeding particles to each screen from two opposing sides of each screen and for evenly distributing The capacity of five separate fine particle wet screening machines in the footprint of one! The Derrick Stack Sizer® redefines fine particle wet screening, offering high capacity and exceptional efficiency in minimal space Consisting of up to five individual screen decks positioned one above the other and operating in parallel,FINE SCREENINGWet fine particle sizing and separating apparatus United States Patent Application Kind Code: A1 Abstract: A particle sizing and separating apparatus is disclosed The apparatus includes a base and a frame that is movably connected to the base A motor assembly is provided to vibrate the frame and at least two screens are connected to the frame Wet fine particle sizing and separating apparatus

Vibrating Screen For Fine Particle tostainpaysagesfr

loose density of selected materials generally, materials with large bulk density and block particles are easy to pass through the sieve, and the screening efficiency is highFor wet fine particle size separation ranging from 1/2 inch to 100 mesh for wet sizing of specialty sand for mill discharge screen in fine grinding circuit for scalping removal of coarse materials curved deck sizing Increasing demands on separation efficiency, a reduction of the cut point and the increase in throughput rates of wet sizing screens for fineparticle minerals have triggered developments at Wet sizing of fine mesh material using the Derrick Stack SizerFor wet fine particle size separation ranging from 1/2 inch to 100 mesh For wet sizing of specialty sand For mill discharge screen in fine grinding circuit For scalping (Removal of coarse materials) Curved Deck Sizing Screen features: High frequency linear stroke vibrating motion Combined sieve bend screen and inclined flat screenSpecialty Screens Classification and Flotation Systems

wet screening undersize

The Repulp wet sizing screen is the ideal machine for the production of a clean oversize material free of fines or undersize particles The Repulp screen is Read More Fine Sizing with the Stack Sizer Screen CEEC wet screening a practical reality in mineral processing operations worldwide In fine particle wet screening, the undersize particles are transported through WINNER Distribution ScreenD is a linear vibration produced by highfrequency dualvibration motors rotating in opposite directions, which makes Distribution screenDfine particle size beneficiation and Download Citation Highspeed screening in the fine and extremely fine particle size ranges Highspeed screens are suitable for many especially demanding sizing Highspeed screening in the fine and extremely fine

wet screen sizing mgsteuerkanzleide

The machine design is based on the following wet sizing principles: Sufficient water coupled with highfrequency vibration is necessary to allow fine solids to pass through a screen Slurry must be introduced to the screen surfaces in uniform, thin layers Oversize material must be quickly Derrick Repulp, wet screening, vibratory screens Multiple Machine Sizes Configurations