gold lagging belt nveyor pulley drum r

2022-07-07T10:07:19+00:00

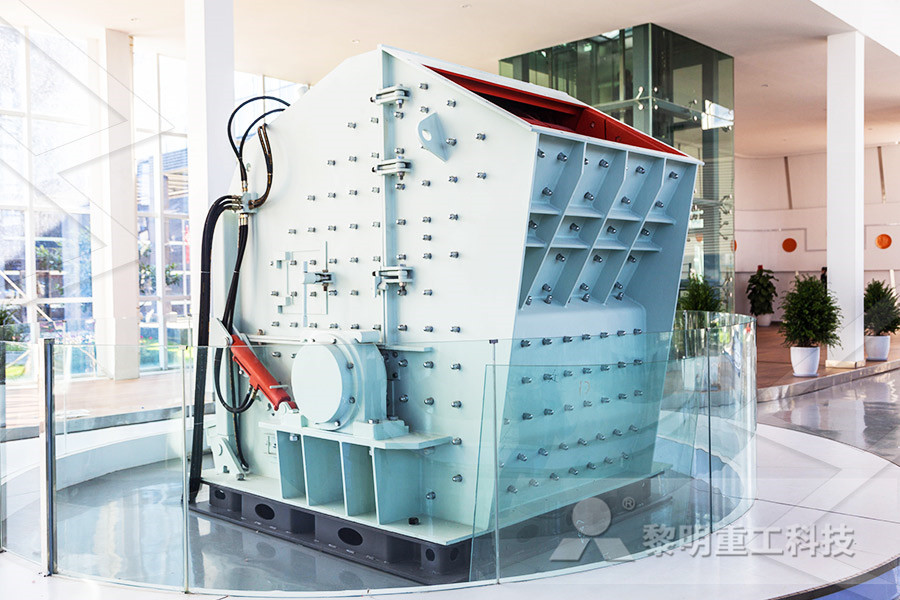

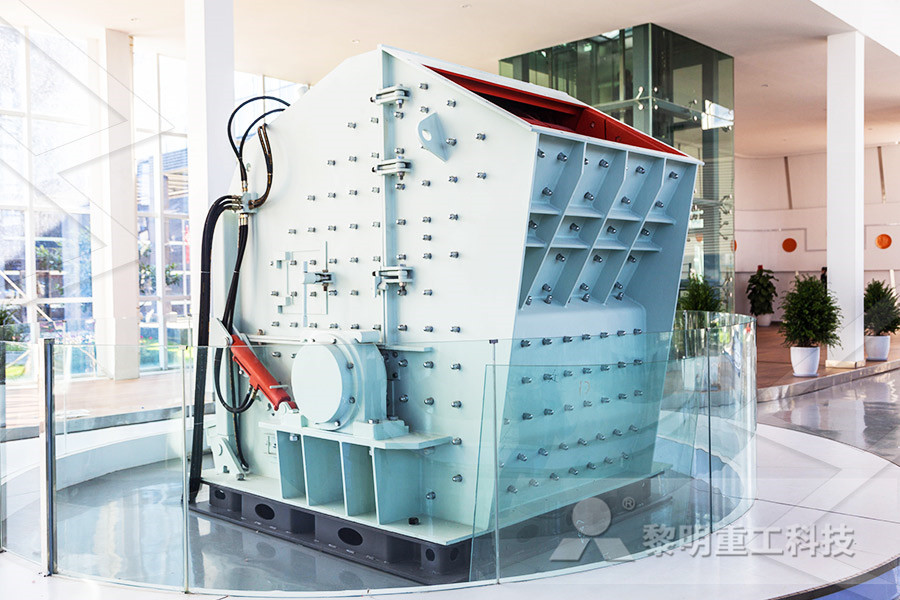

Drum Pulley Lagging All State Conveyors Innovative

14/06/2018 Pulley lagging protects your conveyor belt from potential wear and abrasion If you lag your drive pulley it will result in greater durability because it will assist with the effectiveness of the drive and of the apparent friction between the The Conveyor pulley lagging is a very important part of the belt conveying the transportation system It can reduce belt slippage, improve tracking, and extends the life of the belt, bearing other components It’s widely used in many industries, such as Power, coal mine, cement plant, steel, metallurgy, coal, chemical fertilizer, grain depot, port, and other industries Contents A Complete Guide for Conveyor Pulley Lagging Installation21/09/2020 The function of conveyor pulley lagging is to increase friction with the conveyor belt while protecting the shell from damage There are several types of pulley lagging, including rubber and ceramic lagging Each specific type of pulley lagging has different specifications and purposes which we go into more detail in this articleWhat are the Types of Conveyor Pulley Lagging? Luff

Pulley Lagging Rubber Sheet Suppliers Conveyor Belt

What is Pulley Lagging The Drum is the power source for the conveyor system, it is gradually oxidized in harsh working conditions and some chemicals will chemically corrode it too Therefore, it is necessary to cover with corrosionresistant aging resistance pulley lagging to protect the drum In a word, pulley lagging is the layer of material, which is sticks to the conveyor 04/08/2018 Drum lagging also assists the conveyor belt when it is has a tendency to aqua plane in wet weather or in adverse tracking situations All State Conveyors provide primarily 2 lagging options: Plain Rubber and Grooved Rubber Lagging; Rubber Backed Ceramic Tile Lagging; Read below for the full details of our lagging options and recommendations for drive Pulley lagging Options Plain Grooved Rubber Ceramic Pulley lagging increases the traction between the belt and the pulley, which in turn reduces load and wear on the drive, belt, pulleys, bearings and takeup Lagged in shop or in place on system For efficient and economical conveyor operation, proper pulley lagging is integral detail Extends the life – of key conveyor componentsPulley Lagging Services Pulley Lagging Stop Conveyor

CONVEYOR PULLEY SELECTION GUIDE

Contact Surfaces (Lagging, Knurling) Material Selection Performance Requirements (Runout versus Concentricity) INTRODUCTION Conveyor pulleys play an essential role in the performance and reliability of belt conveyor systems worldwide It is because of this essential role that pulley selection becomes a critical process in keeping equipment up and running If Drum Lagging Drive drums are lagged to provide traction, with the aim of stopping the conveyor belt from slipping There are several options for drum lagging in industry, including plain rubber 60 shore, providing extra protection from wear for tail drums and clean side snubs Plain rubber 40 shore is ideal for its anticaking properties when Drum Lagging UK Rubber BeltingWELDON LAGGING; CERAMIC LAGGING; All our conveyor pulleys are shot blasted to a high standard – this preparatory work allows our highly skilled lagging operatives to achieve the perfect bond between steel and rubber Specdrum offer HOT VULCANISING on all our drum pulleys, with the standard hardness for pulley lagging being 65 shore; other durometers can Lagging Specdrum Engineering

Bondable and WeldOn Pulley Lagging Flexco

Conveyor pulley lagging is an essential part of a belt conveyor system, protecting the pulley and ensuring that there is proper friction between the pulley and the conveyor belt When a pulley is not properly lagged, you can experience belt slippage and even increased belt wear Types of Pulley Lagging Flexco offers two main types of lagging: bondable and weldon Gold Lagging Belt Conveyor Pulley Drum A conveyor pulley used for the purpose of driving a conveyor belt normally mounted in external type bearings and driven by a motor and reducer conveyor head pulleys can be flat faced or crowned and many have lagging to reduce belt slippage conveyor drum pulleys wing pulleys and spiral pulleys are the most common style of Gold Lagging Belt Conveyor Pulley Drum MoulisDrum lagging also assists the conveyor belt when it is has a tendency to aqua plane in wet weather or in adverse tracking situations All State Conveyors provide primarily 2 lagging options: Plain Rubber and Grooved Rubber Lagging; Rubber Backed Ceramic Tile Lagging; Read below for the full details of our lagging options and recommendations for drive and nondrive pulley Pulley lagging Options Plain Grooved Rubber Ceramic

Pulley Lagging Services Pulley Lagging Stop Conveyor

Pulley lagging increases the traction between the belt and the pulley, which in turn reduces load and wear on the drive, belt, pulleys, bearings and takeup Lagged in shop or in place on system For efficient and economical conveyor operation, proper pulley lagging is integral detail Extends the life – of key conveyor componentsWith a pulley lagging system, your pulley and conveyor belt remain in contact at all times This increases friction and prevents the belt from slipping – which would otherwise rapidly ruin your belt, especially at high rotation speeds Outotec offers a broad range of pulley lagging systems, supplying everything from the most basic to the most technically advanced productsConveyor pulley lagging OutotecWhat is Pulley Lagging The Drum is the power source for the conveyor system, it is gradually oxidized in harsh working conditions and some chemicals will chemically corrode it too Therefore, it is necessary to cover with corrosionresistant aging resistance pulley lagging to protect the drum In a word, pulley lagging is the layer of material, which is sticks to the conveyor Pulley Lagging Rubber Sheet Suppliers Conveyor Belt

Lagging Specdrum Engineering

WELDON LAGGING; CERAMIC LAGGING; All our conveyor pulleys are shot blasted to a high standard – this preparatory work allows our highly skilled lagging operatives to achieve the perfect bond between steel and rubber Specdrum offer HOT VULCANISING on all our drum pulleys, with the standard hardness for pulley lagging being 65 shore; other durometers can Belt Conveyor Drum Pulleys China Manufacturers, Factory, Suppliers We intention to see quality disfigurement within the creation and supply the ideal support to domestic and overseas buyers wholeheartedly for Belt Conveyor Drum Pulleys, Conveyor Drive Pulley, Metal Cone Roller Herb Grinder, Conveyor Belt Sushi Hakata Station,Conveyor Roller Belt Conveyor Drum Pulleys TX ROLLERContact Surfaces (Lagging, Knurling) Material Selection Performance Requirements (Runout versus Concentricity) INTRODUCTION Conveyor pulleys play an essential role in the performance and reliability of belt conveyor systems worldwide It is because of this essential role that pulley selection becomes a critical process in keeping equipment up and running If CONVEYOR PULLEY SELECTION GUIDE

Drum Pulleys for Conveyor Douglas Manufacturing

Drum pulleys are engineered by the professionals at Douglas to be the most durable pulleys in industry They are developed using a combination of more than 40 years of experience and state of the art computer design and analysis tools All Douglas drum pulleys feature our exclusive single piece rolled rim, solid steel pipe or tubing design that 10/05/2019 Pulley Design Features Pulley Hub Design Shafting Pulley Lagging In belt conveyor application, a pulley’s purpose is primarily threefold, 1) support the belt in directional changes, as designed in the conveyor, 2) transmit driving power to the belt, and 3) guide or train the belt The drive pulley imparts the driving force to the belt Conveyor Belt Pulleys Design FeaturesDrum lagging also assists the conveyor belt when it is has a tendency to aqua plane in wet weather or in adverse tracking situations All State Conveyors provide primarily 2 lagging options: Plain Rubber and Grooved Rubber Lagging; Rubber Backed Ceramic Tile Lagging; Read below for the full details of our lagging options and recommendations for drive and nondrive pulley Pulley lagging Options Plain Grooved Rubber Ceramic

Supply Conveyor Rubber Lagging Drum Pulley Wholesale

If the pulley is not coated with rubber lagging, it is easy to cause the conveyor belt slip in the highstrength conveying system, which is not conducive to the normal operation of the conveying system The rubber lagging pulley can solve a lot of unnecessary trouble In addition, the conveyor rubber lagging pulley also has an obvious advantage, that is, it can clean itself and Conveyor Belt Plain Rubber Drum Pulley Lagging is a abrasion resistant rubber friction cover sheet with shore hardness of 60 + 5% designed in a plain type, which increase the friction value between drum belt available in different thickness sizes Pulley Lagging Rubber Sheets are designed to improve the friction coefficient between the Tail Pulley and the Conveyor Belt Drum Pulley Lagging Services Sai Conveyor BeltContact Surfaces (Lagging, Knurling) Material Selection Performance Requirements (Runout versus Concentricity) INTRODUCTION Conveyor pulleys play an essential role in the performance and reliability of belt conveyor systems worldwide It is because of this essential role that pulley selection becomes a critical process in keeping equipment up and running If CONVEYOR PULLEY SELECTION GUIDE

Bondable and WeldOn Pulley Lagging Flexco

Conveyor pulley lagging is an essential part of a belt conveyor system, protecting the pulley and ensuring that there is proper friction between the pulley and the conveyor belt When a pulley is not properly lagged, you can experience belt slippage and even increased belt wear Types of Pulley Lagging Flexco offers two main types of lagging: bondable and weldon Different Lagging Type:Product Features:Conveyor Pulley is the main transmission belt conveyor components, there are two Rubber Lagging Belt Conveyor Pulley Drum Model NO XHHP Welding Method Carbon Dioxide Gas Shielded ArcWelding Machine Certification ISO 9001, ISO14001, ISO8001, SGS, Ce Working Lifetime Over 50000 Hours Bearing Rubber Lagging Belt Conveyor Pulley Drum SupplyConveyor Ceramic Pulley Lagging39% Ceramic Tiles Coverage General Purpose Conveyor Ceramic drum lagging is especially suited for drums with slippage and excessive wear tear problems which make normal rubber lagging ineffective View details; Ceramic Rubber Pulley Lagging58% Ceramic tiles coverage Anti Slipping Purpose Ceramic rubber pulley lagging( Wear resistance weldable drum lagging for belt conveyor

Martin HeavyDuty Conveyor Pulleys and Idlers Brochure

Drum Pulley • 14" to 36" diameter • 25" to 375" Minimum Rim Thickness • 1" and Heavier End Discs • 5" Center Plates • Full Depth Key Bushings • Rolled rim, trimmed and hydraulically seated around end discs • Several hub/bushing system options • Double SubArc Weldment • Crowned face, flat face available upon request Quarry Duty AR Wing Pulley • Available in 10" thru TELEPHONE: +44 (0)1623 FAX: +44 (0)1623 : form Conveyor Drums AB Conveyors