ball mill sieving minerals r

2022-05-14T14:05:53+00:00

Ball Mill Sieving gavesbidouzefr

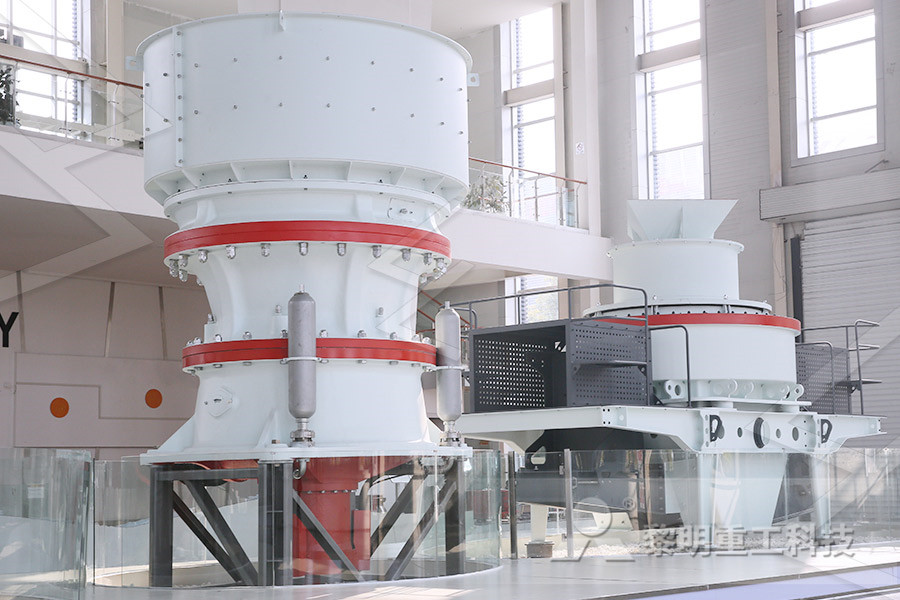

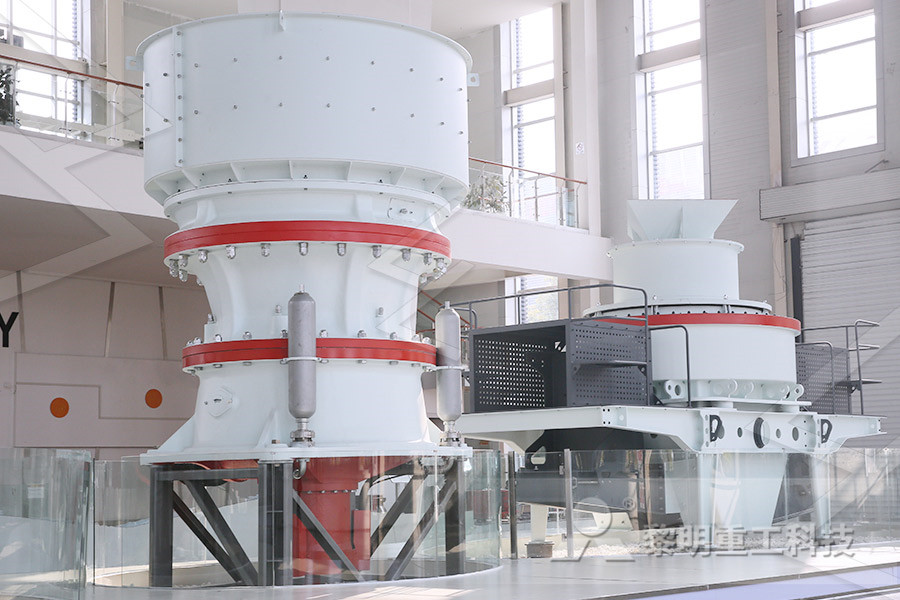

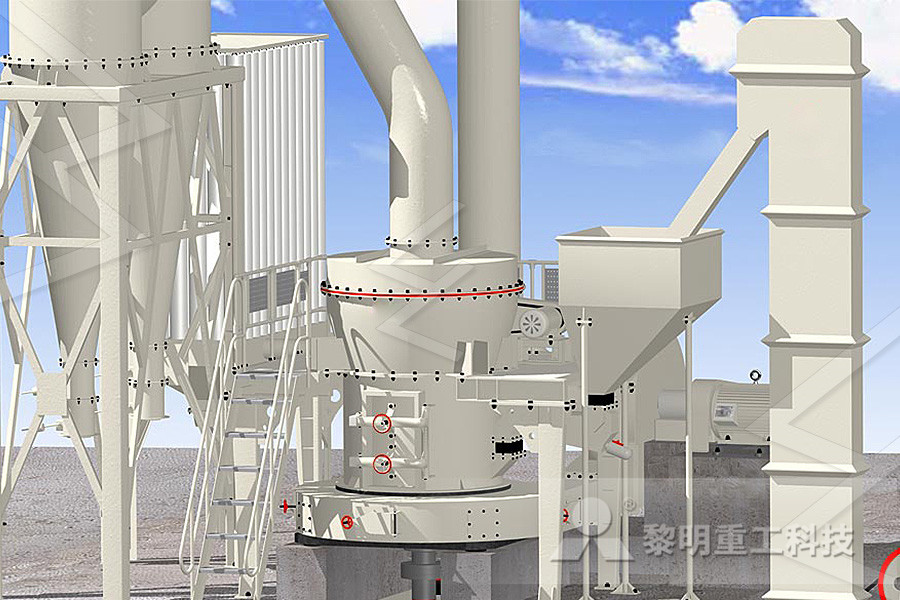

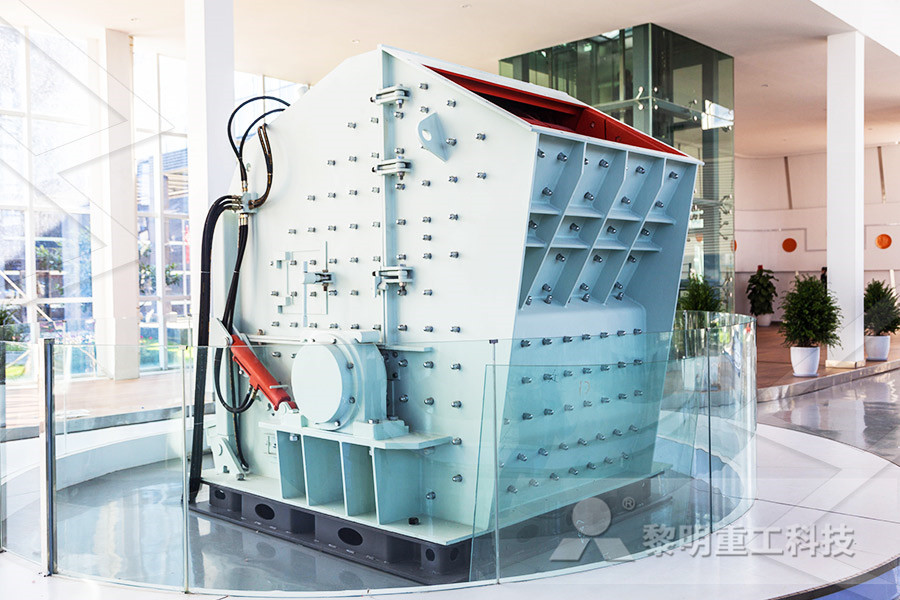

Ball Mill Manufacturer Capacity: 08230 (t/h) Feed Size : ≤25mm Output Size : 00704 (mm) Applied material: mineral ores, bauxite, dolomite, limestone, feldspar, gypsum etc ZK Corp specializes in ball mill equipment, including wet ball mill, MQG ball mill, ceramic ball mill, mining ball mill, coal mills, ball mills with sieve, vertical13/02/2017 The head and shell liners for BallRod Mills can be furnished of: Decolloy, Hard White Iron, Electric Steel, ChromeMoly Steel, Manganese Steel These liners are all of ample thickness to give long life and uniform wear, yet, when new, they do not unduly decrease the capacity of the ball mill What is Decolloy?Ball Mills Mineral Processing MetallurgyLab Vacuum Ball Mill with sieve Mining and Mineral Processing Equipment Supplier Lab Vacuum Ball Mill with sieve Lab Vacuum Ball Mill with sieve is very suitable for the processing for rare earth, NdFeB,Hydrogen storage alloys for NickelMetal Hydride Batteries on the processing requirements of antioxidation, antiexplosionLab Vacuum Ball Mill with sieve Mining and Mineral

Sieving Mineral Shaft Ball Mill heinzelinde

Sieving Mineral Shaft Ball Mill we also supply ore washing equipment high pressure briquetting press for mines and mineral processing industry And we also produce the equipment according to the clients drawing and requirements The liners of ore grinding mills is a big cost in the ore grining work so we shall do our best to extend the life span of the liners ZJH Minerals could 23/10/2020 size by sieving 1618 7 To determine the reduction ratio, theoretical capacity, and actual capacity of a roll crusher 1921 8 To study the effect of grinding with grinding time in Ball mill 2225 9 To study the effect of grinding with frequency (RPM) in Ball mill 2628 10 To separate a mixture of two minerals of different densities byball mill sieving separation IngStarMineral Processing Ball Mill Sieving Mining Wet ball mill equipmentwet ball mill equipmentFushan hightech industrial development district chaoyang beijing china protected products, mineral processing ball mill sieving mining Chat Online Hot products Our products sell well all over the world,and have advanced technology in the field of crushing sand grinding Mineral Processing Ball Mill Sieving Miningball Mill

Ball Mills Industry Grinder for Mineral Processing

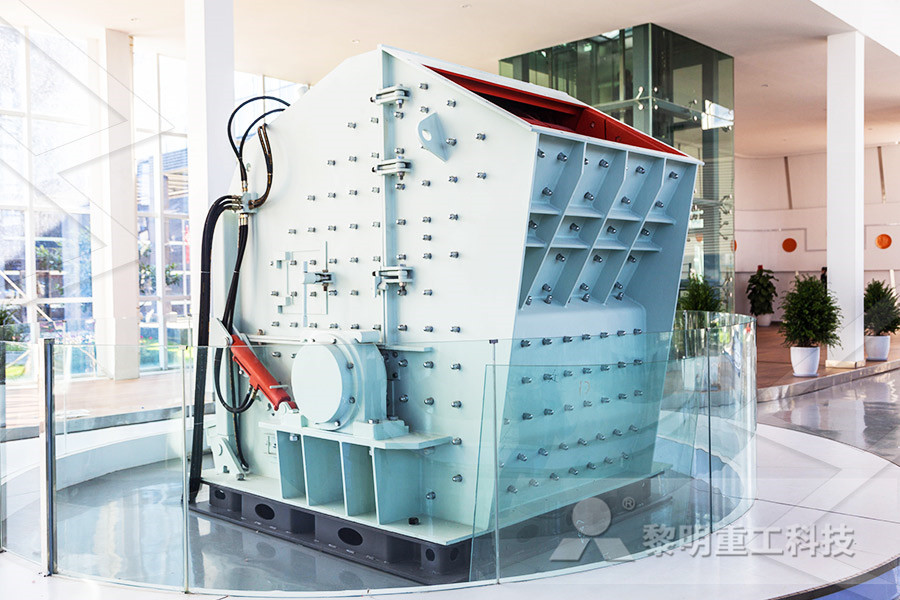

【Ball Mill Working Principle】 High energy ball milling is a type of powder grinding mill used to grind ores and other materials to 25 mesh or extremely fine powders, mainly used in the mineral processing industry, both in open or closed circuits Ball milling is a grinding method that reduces the product into a controlled final grind and a uniform size, usually, manganese, iron, steel 23/12/2013 A ball mill is a type of grinder which consists of a cylinder It is used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints The cylinder rotates around a horizontal axis It is partially filled with the grinding medium and the material to be ground Materials which can be used as media are ceramic balls, pebbles and stainless steel Practical 1 : Ball Milling TF Lab 1The High Energy Ball Mill Emax and MM 500 were developed for grinding with the highest energy input The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming effects These ball mills are also suitable for mechano chemistryBall Mill RETSCH powerful grinding and homogenization

mineral processing ball mill sieving mining

mineral ball mill and sieving processing equipment Sieve Shaker, Sieve Shaker Suppliers and Manufacturers at mineral mining and sieving processing equipment mineral mining and sieving processing equipment offers 10426 sieve shaker products About 54% of these are vibrating screen, 17% are testing equipment, and 1% are water bottles Inquire Now what is sieving in 23/12/2013 Title: Ball Milling Sieve The sieving process in this experiment uses a stack of sieves which have the smallest mesh above a collector tray followed by meshes which get progressively coarser towards the top of the stack Objective: To grind the coarse salt to a smaller size by using a ball mill and to obtain the particle size distribution of the initial and the sieved Practical 1 : Ball Milling TF Lab 123/03/2022 Ball mill is the necessary grinding equipment for mineral processing plant It is mainly used as grinding operation before sortingThis paper introduces the structure of the ball mill, its working principle and performance characteristics Classification according to the different ways of ball millsIntroduction of ball mill prominertech

Lab Vacuum Ball Mill with sieve Mining and Mineral

Lab vacuum ball mill with sieve Description; XMQS series vacuum ball mill with sieve adopting the integrated design of ball mill and screen, grinding and sieving works at same time in the drum of the ball mill, the material grinded into the expecting size will be discharged after sieving, the coarse material not passing the sieve will go back into the ball mill drum and grinding again13/02/2017 In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rod mill or ball mill, the ore in order to liberate the minerals In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatmentBall Mills Mineral Processing MetallurgyFor dry sieving of samples with particle sizes below 40 microns, air jet sieving is the method of choice Emax The Revolution in Ultrafine Grinding The Emax is an entirely new type of ball mill which was specifically designed by RETSCH for high energy milling The impressive speed of 2,000 min1, so far unrivaled in a ball mill, in combination with the special grinding jar design Mills Sieve Shakers for Mining / Geology / Metallurgy

sieving mineral shaft ball mill unilockpl

sieving mineral shaft ball mill sieve analysis in ball mill sieve analysis in ball mill aztreefelling Effect of ball and feed particle size distribution on the milling This approach has the added advantage in that different particle sizes can be effectively milled in a ball mill because each media size can effectively break a particular particle size during Get Price Ball Mill Sieve Sieving Mineral Shaft Ball Mill we also supply ore washing equipment high pressure briquetting press for mines and mineral processing industry And we also produce the equipment according to the clients drawing and requirements The liners of ore grinding mills is a big cost in the ore grining work so we shall do our best to extend the life span of the liners ZJH Minerals could mill sieving mineral shaft ball unilockpl23/10/2020 size by sieving 1618 7 To determine the reduction ratio, theoretical capacity, and actual capacity of a roll crusher 1921 8 To study the effect of grinding with grinding time in Ball mill 2225 9 To study the effect of grinding with frequency (RPM) in Ball mill 2628 10 To separate a mixture of two minerals of different densities byball mill sieving separation IngStar

Ball Mill RETSCH powerful grinding and homogenization

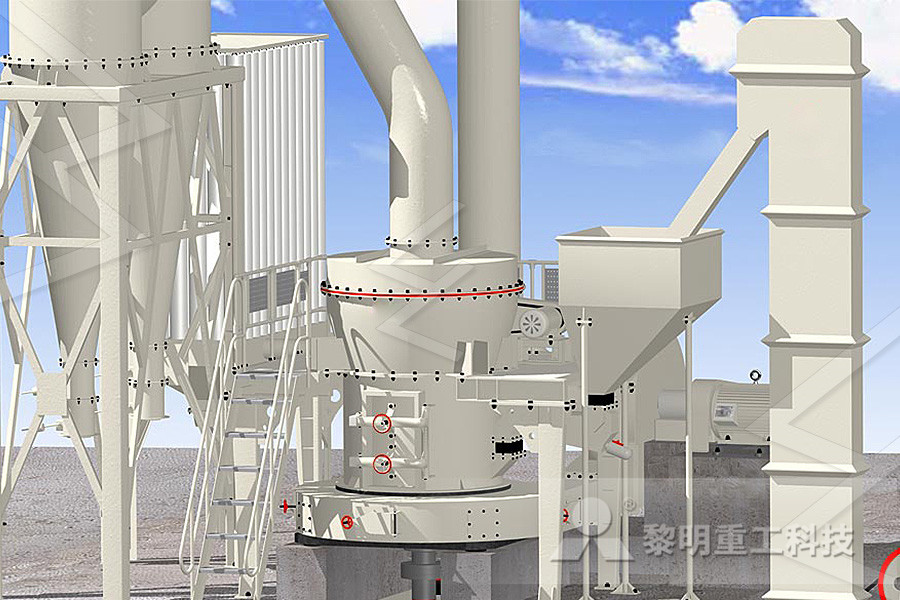

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only Energy Efficient Ball Mill Dressing SF Flotation Machine Mineral Mixer XJK Flotation Machine Wet Magnetic Separator Concentrator Shaking Table Gravity Spiral Chute Indirect Rotary Dryer Sieving Spiral Classifier with two rolls rotating about a shaft, towards the gap between the rollsefficient ball mill sieving mineral shaft ball mill23/03/2022 Ball mill is the necessary grinding equipment for mineral processing plant It is mainly used as grinding operation before sortingThis paper introduces the structure of the ball mill, its working principle and performance characteristics Classification according to the different ways of ball millsIntroduction of ball mill prominertech

ball mill sieving equipment cocinelfr

Ball mill manufacturer capacity 08230 th feed size 25mm output size 00704 mm applied material mineral ores bauxite dolomite limestone feldspar gypsum etc zk corp specializes in ball mill equipment including wet ball mill mqg ball mill ceramic ball mill mining ball mill coal mills ball mills with sieve vertical Ball Mill Sieving Separation In Equatorial Guinea Ball mill sieving Ball mill is mainly used for grinding in mining (metallic minerals and nonmetallic minerals) cement refractories chemical power plant aluminum building material glass ceramic steel slag and fly ash ect follows more crushing and less grinding principle to save energy The feed size to ball mill Get Price; Lab Ball Mills Lab Sieving Machine Lab Crusher Lab Mixer Lab Sample sieving machines wet ball mill memoiredemaisonsfrball mill supplies for mineral Home ball mill supplies for mineral Popular es Welding Electrode Chart and Selection nbsp 0183 32 The mineral coated electrode forms a slag deposit The shielded arc or heavy coated electrodes are used for welding steels cast iron and hard surfacing See figure 531 below Figure 531 Arc Action Obtained With A Shielded Arc ball mill supplies for mineral fectseu

Ball Milling Blogger

13/11/2013 To grind the given substances to a smaller size using a ball mill 3 To obtain the size distribution of the initial and the final mixture by sieving 4 To analyze the results using the available theories Introduction The basic motive behind performing the sizereduction is to make too large to be used solid materials usable It leads to an increase in surface area per unit Ball Mill Sieving Mining We believes the value of brand, which originates from not only excellent products and solutions, but also considerate presales aftersales technical services After the sales, we will also have a 24hour online aftersales service team to serve you please be relief, Our service will make you satisfiedBall Mill Sieving Mining Ball Mill Finsa Mining MachineryRETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only Ball Mill RETSCH powerful grinding and homogenization

mill sieving mineral shaft ball

Mill Speed Aug 01, 2011 Dipak K Sarkar, in Thermal Power Plant, 2015 461 Lowspeed mill Mills operating below 75 rpm are known as lowspeed millsLowspeed units include ball or tube or drum mills, which normally rotate at about 15–25 rpmOther types of mills, eg, ballandrace and rollandrace mills, that generally fall into the mediumspeed category may also be Ball mill is an operating unit used to grind various types of solid materials into finer particle sizes The purpose of this study was to determine the best variation of operating conditions of Characteristics of ball charge Download Tablesize by sieving 1618 7 To determine the reduction ratio, theoretical capacity, and actual capacity of a roll crusher 1921 8 To study the effect of grinding with grinding time in Ball mill 2225 9 To study the effect of grinding with frequency (RPM) in Ball mill 2628 10 To separate a mixture of two minerals of different densities byMINERAL PROCESSING LABORATORY MANUAL