iron ore mineral processing plants

2020-02-22T00:02:12+00:00

Iron ore Processing Plant

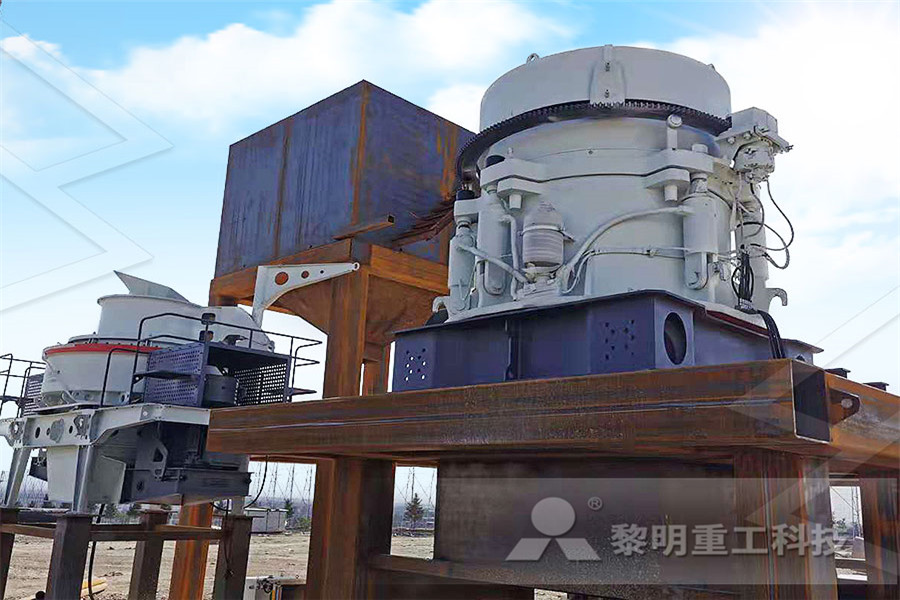

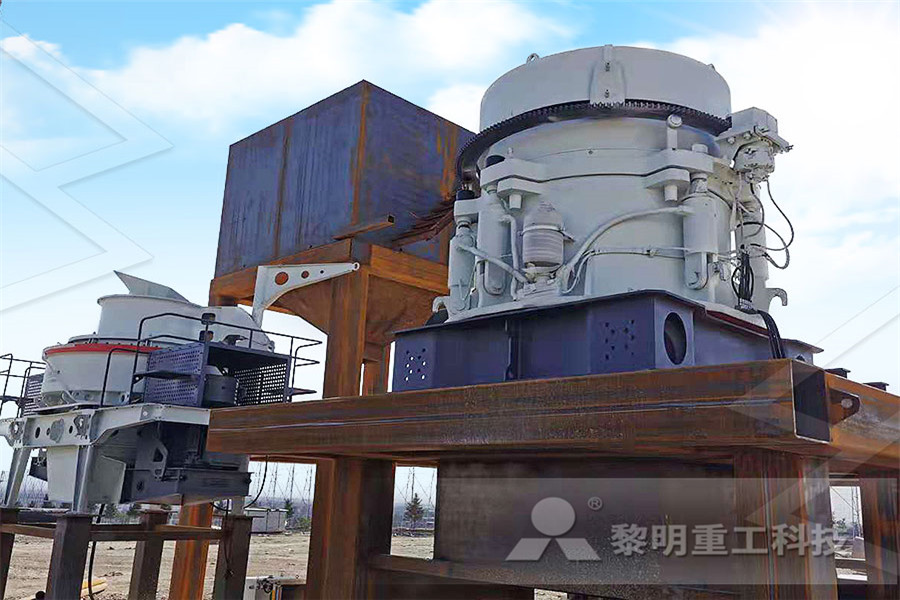

Iron ore Processing Plant At present, there are about 300 kinds of ironbearing minerals found in nature According to the classification of chemical composition, the common iron ore mainly includes magnetite, hematite, limonite and siderite Different properties of iron ore, its processing technology is naturally different The current iron ores beneficiation plant generally through the crusher crushed the raw ore, and then into the ball mill smashed through the gravity separation, flotation , extracted from the concentrate and tailings, and through chemical methods, and iron ore beneficiation products eventually become finished productsIron Ore Processing Plant Shanghai CompanyIron Ore Processing Iron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be Iron Ore Processing,Crushing,Grinding Plant

Iron Ore Processing Plant Iron Ore Processing Plant

We offer turnkey solutions for iron ore processing plants Fabricated from the highest quality raw materials, these plants are provided with Feed Hopper, Ball Mill for grinding, Wash drum (Scrubber), Spiral Classifier bank, Hydro cyclones bank, Multideck Rectangle Vibratory Screens, Low; Medium highIntensity Magnetic Separators, and Tailing Pond the ball mill and spiral classifier is for grinding the iron ore and making sure the size of the final product to 00074mm the magnetic separator is for separating the iron concentrate The capacity for these plants can be customized as per request such as 10tph, 50tph,100tph, etcIron Ore Washing Processing Mineral ProcessingIndustrial Mineral Processing Plant We are one of the leading manufacturer and exporter of Mineral Ore Beneficiation Plant Machines, fabricated from Industrial Mineral Processing Plant Iron Ore

The Latest Developments in Iron Ore Processing

–Process 600t/h lumpy iron ore • DMS Cyclone –Only 6mm material for iron ore –360mm diameter cyclone –Process 40t/h per cyclone • Larcodems –90+6mm stones –12m diameter –Operating capacity of 600800t/h –Efficient separation at SG’s as high as 41g/cm3 Dense Media Separation on Iron Ore •Mineral Processing In Iron ore and Coal, mineral processing plays a vital role Our expertise lies in design, engineering, procurement, installation and commissioning a mineral processing plant Our own EPCC team has designed and commissioned one of the biggest processing plants in India ie 1500 tph Central Processing Unit in Balda Block Mineral Processing Thriveni Earth Movers Pvt Ltd Crushing and screening is typically the first step of iron ore beneficiation processes In most ores, including iron ore, valuable minerals are usually intergrown with gangue minerals, so the minerals need to be separated in order to be liberated This screening is an essential step prior to their separation into ore product and waste rockLife cycle assessment of iron ore mining and processing

BENEFICIATION OF IRON ORE nitrklac

Iron ore belongs to Precambrian stage and its deposit is present in massive, laminated, friable and also in powdery form Its major deposits are in Jharkhand, Orissa, Chhattisgarh, Karnataka and Goa States 211 Hematite: It is most important iron ore mineral main source for industriesOur iron ore processing plants can be retrofitted to your existing Raw Material Handling (RMH) system to facilitate the processing of mined iron ore before it is fed to the furnace The processing of iron ore delivers significant efficiencies to your operations Efficient Kiln Operation with clean Calibrated Lump Ore (CLO)Iron ore processing plant CDE AsiaThe processing takes place in three stages sorting concentration and pelletizing Once the iron ore concentrate has passed the pelletizing plant the end product – small round iron ore balls known as iron ore pellets – is ready for onward transport to our customersprocessing plant for iron ore and earth galaxyanimationit

iron ore mineral processing plants styropianwawpl

Iron ore grinding mill Grinding plants for Iron Ore Iron ore is an important industrial source, is an iron oxide ore, a mineral aggregate containing iron elements or iron compounds that can be economically utilized, and there are many types of iron oreKnowing that not all clients are the same and that all applications differ was the driving force behind the MAX Plant range of equipment From the beginning the team at MAX Plant looked at innovation as the driving force and how the portability can make a difference to the capital costs of setting up a mineral processing plant, whether in a mining application or a quarry application MAX Plant Iron Ore Processing ProjectsWe use cookies to improve your experience on our website By using our site you agree to Cookies PolicyIron Ore Processing Flowsheet Multotec

The Latest Developments in Iron Ore Processing

–Process 600t/h lumpy iron ore • DMS Cyclone –Only 6mm material for iron ore –360mm diameter cyclone –Process 40t/h per cyclone • Larcodems –90+6mm stones –12m diameter –Operating capacity of 600800t/h –Efficient separation at SG’s as high as 41g/cm3 Dense Media Separation on Iron Ore •Mineral Processing In Iron ore and Coal, mineral processing plays a vital role Our expertise lies in design, engineering, procurement, installation and commissioning a mineral processing plant Our own EPCC team has designed and commissioned one of the biggest processing plants in India ie 1500 tph Central Processing Unit in Balda Block Mineral Processing Thriveni Earth Movers Pvt LtdHematite (Fe2O3) is a kind of weak magnetic mineral, and its crystal belongs to the oxide mineral of hexagonal crystal system The mineral form is dominated by iron oxide According to its composition, hematite ore can be divided into four varieties, including ilmenite, aluminum hematite, magnesium hematite and hydrohematiteIron Ore Processing, Process of Iron Mining, Iron

Beneficiation of Iron Ore Mineral Processing

Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practiceThis also applies to iron ores of the nonmagnetic type which after a reducing roast closure of multiple iron ore plants Total raw steel production was estimated to have decreased to 69 million tons in 2020 from 878 million tons in 2019 The share of steel produced by basic oxygen furnaces, the process that uses iron ore, continued to decline from 373% in 2015 to an estimated 30% in 2020 owing to increased use of electric arcIRON ORE1 USGSOur iron ore processing plants can be retrofitted to your existing Raw Material Handling (RMH) system to facilitate the processing of mined iron ore before it is fed to the furnace The processing of iron ore delivers significant efficiencies to your operations Efficient Kiln Operation with clean Calibrated Lump Ore (CLO)Iron ore processing plant CDE Asia

Iron Ore Processing Flowsheet Multotec

We use cookies to improve your experience on our website By using our site you agree to Cookies PolicyIndustrial Mineral Processing Plant We are one of the leading manufacturer and exporter of Mineral Ore Beneficiation Plant Machines, fabricated from superior quality of raw materialsThese plants machines, specially designed for Industrial Mineral Processing Plant Iron Ore Mining of iron ore is a highly capital and energyintensive process Life cycle assessment (LCA) of the mining and mineral processing of iron ore in Australia was carried out in this chapter using SimaPro LCA software as a case study The environmental impacts considered in the study were embodied energy and greenhouse gas (GHG) emissions Life cycle assessment of iron ore mining and processing

MAX Plant Iron Ore Processing Projects

Knowing that not all clients are the same and that all applications differ was the driving force behind the MAX Plant range of equipment From the beginning the team at MAX Plant looked at innovation as the driving force and how the portability can make a difference to the capital costs of setting up a mineral processing plant, whether in a mining application or a quarry application been conducted on the material processing plants Simulation and modelling of mineral processing systems focuses on design and optimization of circuits and machine performances The focus of this project is on simulating the interactions between interior components of a plant a discrete using event approachAn ordinary iron ore processing plant Discrete Event Simulation of an Iron Ore Milling Process Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practiceThis also applies to iron ores of the nonmagnetic type which after a reducing roast Beneficiation of Iron Ore Mineral Processing

bオャャ・エゥョ@ッヲ@エィ・@g・ッャッァゥ」。ャ@sッ

MINERALOGICAL INVESTIGATION AND MINERAL PROCESSING OF IRON ORE FROM THE SKINES AREA (CHANIA – WEST CRETE) Trichos D1, Alevizos G1, Stratakis A1, Petrakis E1 and Galetakis M 1 1 Technical Evolution of binders for iron ore pelletizing Induration technologies Challenges and innovations in iron ore pelletizing 2 Pelletizing process and raw materials The iron ore is mined mostly from open pit deposits through mining operations and the raw product, run of mine, is subjected to mineral processingIron Ore Pelletizing Process: An Overview IntechOpen Top five largest iron ore producing companies in the world in 2020 1 Vale – 300 million tonnes Brazilian miner Vale was the world’s top producer of iron ore in 2020, with an output totalling just over 300 million tonnes – a small Top five iron ore producing companies in 2020