magnetic separation mineral dressing r

2022-12-31T00:12:44+00:00

magnetic separation mineral dressing

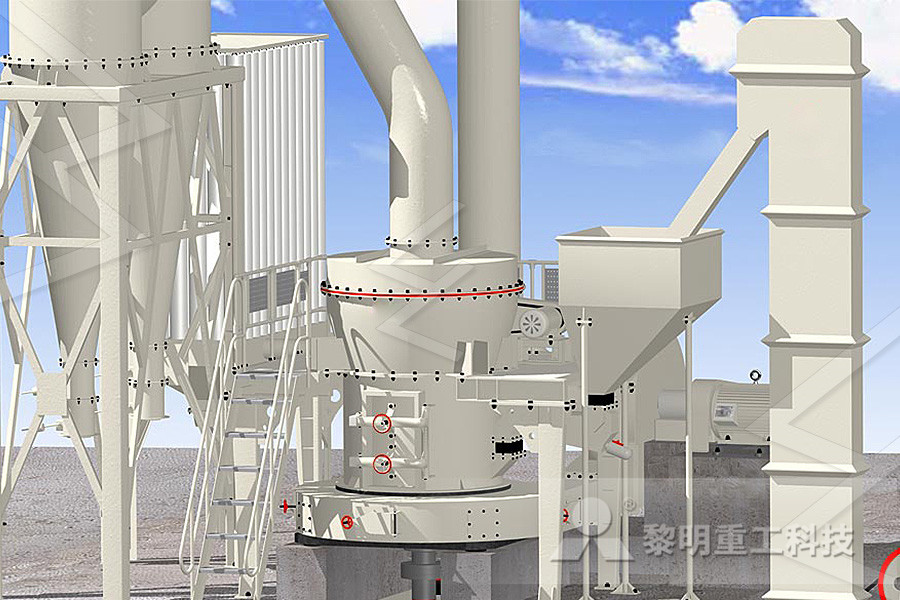

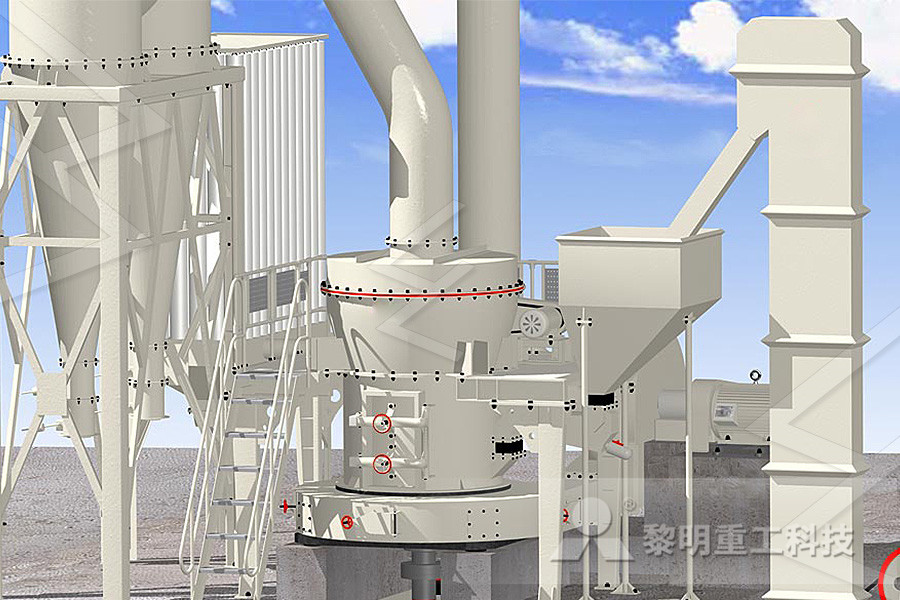

Weak magnetic mineral could use the strong magnetic mineral separation process after the magnetizing and roasting Fine Grinding In two stages grinding, stages separation, single weak magnetic flow, fine grinding means adding fine screen regrinding process to separate fine minerals timely and reduce the overgrinding read more 08 Dec, 2020 Mineral dressing (= Kaolin Magnetic Separation Process Mineral Processing Equipment Ore Dressing Use WDY Mineral Processing provides a wide range of ore beneficiation research services for the mining industry It offers a unique platform for the development and testing of energysaving, low environmentalimpact crushing, grinding and concentration processesmagnetic separation mineral dressingMagnetic separation is a widely used mineral separation method based on the difference of magnetic properties between different minerals, separate target minerals in the inhomogeneous magnetic field The magnetic separator is used for mineral ore dressing of magnetite, pyrrhotite, ilmenite, wolframite, manganese, rare earth ore and otherMagnetic Separation Mineral Dressing

Magnetic Separators for Mining Mineral Processing

08/07/2020 Dry highintensity magnetic separators The mineral industry has always had a great demand for beneficiation equipment capable of performing coarse and weak magnetic minerals The development of permanent magnetic materials and the improvement of their magnetic properties are undoubtedly one of the main driving forces for the progress of dry 01/07/2020 And magnetic separation is the main method of iron ore dressing What minerals are required for magnetic separation? Common Iron Minerals are magnetite (strong magnetic minerals), hematite (weak magnetic minerals), Limonite, specularite, siderite (all weak magnetic minerals) They are raw materials for the steel industry The iron ore grade is low, many Types of Mining Magnetic Separators Mineral Processing22/10/2018 Typical magnetic separation equipment applications include the removal of iron mineral contamination from silica sands, feldspar and other nonmetallic industrial minerals Rare Earth Roll Magnetic Separators are also used when processing granulated slag, upgrading ilmenite, processing beach sands, and in recycling applications such as removing fine iron Magnetic Separators For Mineral Process Bunting Redditch

Mineral dressing (= Orebeneficiation) kau

Mineral dressing (= Orebeneficiation) The first process most ores undergo after they leave the mine is mineral dressing (processing), also called ore preparation, milling, and ore dressing or ore beneficiation Ore dressing is a process of mechanically separating the grains of ore minerals from the gangue minerals, to produce a concentrate (enrichedWeak magnetic mineral could use the strong magnetic mineral separation process after the magnetizing and roasting Fine Grinding In two stages grinding, stages separation, single weak magnetic flow, fine grinding means adding fine screen regrinding process to separate fine minerals timely and reduce the overgrinding read more 08 Dec, 2020 Mineral dressing (= magnetic separation mineral dressingHome Magnetic Separation Mineral Dressing Copper Ore Processing Equipment Capacity:0187 (m ³/min) Suitable Materials:Copper, zinc, lead, nickel, gold and other nonferrous metals, ferrous and nonmetal View Details Send Enquiry Ceramsite Production Line Production Capacity:705,000 t/d Raw Materials:Clay, mudstone, slate, gangue, coal ash, shale, sludge Magnetic Separation Mineral Dressing

separation methods for mineral dressing

Magnetic separation is an ore dressing process, in which magnetically susceptible minerals are separated from a mixture using a magnetic force It is a method of concentrating the mined material by the application of a magnetic field We use MS to concentrate a valuable ore that contains a mixture of magnetic and nonmagnetic minerals;Kaolin Magnetic Separation Process Mineral Processing Equipment Ore Dressing Use WDY Mineral Processing provides a wide range of ore beneficiation research services for the mining industry It offers a unique platform for the development and testing of energysaving, low environmentalimpact crushing, grinding and concentration processesMagnetic Separation Mineral Dressing Machine MiningKaolin Magnetic Separation Process Mineral Processing Equipment Ore Dressing Use WDY Mineral Processing provides a wide range of ore beneficiation research services for the mining industry It offers a unique platform for the development and testing of energysaving, low environmentalimpact crushing, grinding and concentration processesmagnetic separation mineral dressing

Magnetic Separation of Sulphide Minerals 911 Metallurgist

In the Richards Mineral Dressing lab oratories, the success achieved through the use of this device in separating associated sulphides has been so startling as to lead us to believe that it constitutes a magnificent adjunct to heavyliquid separation and to quantitative mineragraphy as a tool for the mineral investigator THE SEPARATOR The separator (Fig I) consists of: I A magnetic separation mineral dressing Magnetic separation utilizes t he force exerted by a magnetic field upon magnetic materials to mineral dressing is the process of separating commercially valuable minerals from their ores Get A Quote Jaw Crusher; Impact Crusher; Cone Crushers; Sand Maker ; Ball Mill; Raymond Mill; Differences And Applications Of Magnetic magnetic separation mineral dressingWhen you need magnetic separation the Reading range of magnetic separators has a wide range of proven, cost effective products Including wet high intensity, induced roll, rare earth roll, rare earth drum, low intensity and Magnetic Separation Mineral Technologies

magnetic separation mineral dressing

06/05/2021 magnetic separation mineral dressing magnetic separation mineral dressing 147 147, Jul 31, 2021 147 147, Read More, The mineral left on the table will be reground and concentrated The gravity sand concentrated by jig and shaking table will be concentrated in the Process of cleaning CleaningIn this stage Xinhai would always apply the Processing of Mineral dressing (= Orebeneficiation) The first process most ores undergo after they leave the mine is mineral dressing (processing), also called ore preparation, milling, and ore dressing or ore beneficiation Ore dressing is a process of mechanically separating the grains of ore minerals from the gangue minerals, to produce a concentrate (enriched portion) containing most of the Mineral dressing (= Orebeneficiation) kaumagnetic separation mineral dressing Application of magnetic separation types of mixtures ,ms in ore dressing metallurgy In ore beneficiation, the three major applications of the magnetic process are as follow the concentration and separation of valuable minerals from gangue, such as ironsilicates mixtures, rare earthcarbonates ores, etcmagnetic separation mineral dressing

magnetic separation mineral dressing

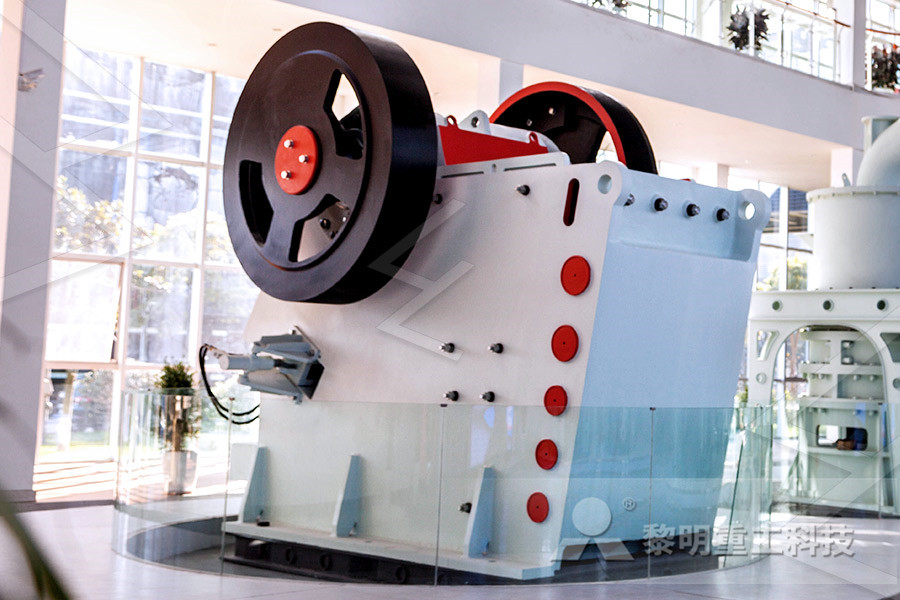

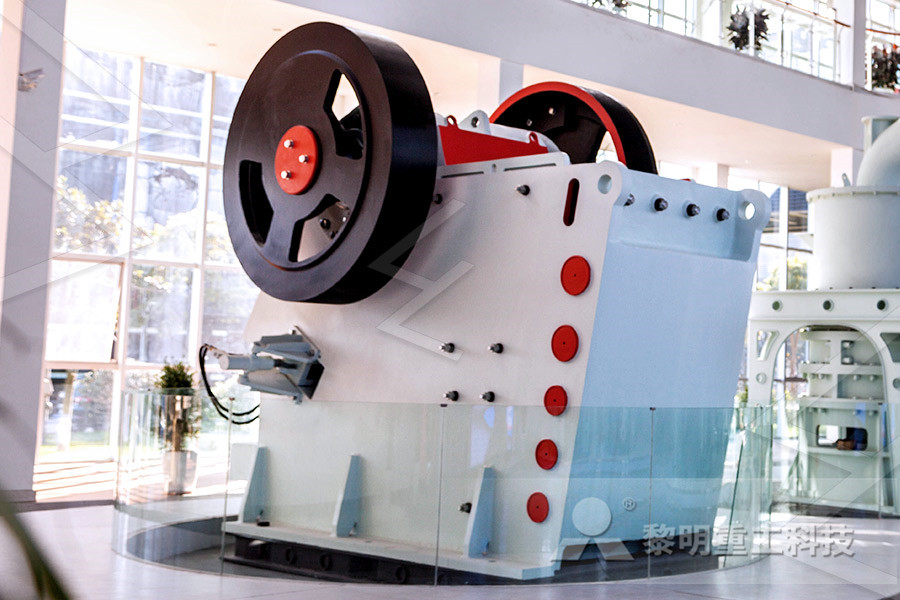

Kaolin Magnetic Separation Process Mineral Processing Equipment Ore Dressing Use WDY Mineral Processing provides a wide range of ore beneficiation research services for the mining industry It offers a unique platform for the development and testing of energysaving, low environmentalimpact crushing, grinding and concentration processesmagnetic separation mineral dressing For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profit more quicklymagnetic separation mineral dressingMagnetic Separation Mineral Dressing We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other sandstone equipmentBall mill, flotation machine, concentrator and other beneficiation equipment Powder Grinding Plant, rotary dryer, briquette machine, mining, metallurgy and other related equipment which can crush allmagnetic separation mineral dressing

Magnetic Separation Mineral Dressing

Magnetic Separation Mineral Dressing Magnetic separation mineral dressingChapter 1 mineral dressing websSlag the objectives of mineral dressing are as follows 1 to eliminate unwanted chemical species to prepare the ore particle from chemical stand point primarily involving the following steps a liberation of dissimilar particles from each other appearing in the magnetic separation mineral dressing Magnetic separation utilizes t he force exerted by a magnetic field upon magnetic materials to mineral dressing is the process of separating commercially valuable minerals from their ores Get A Quote Jaw Crusher; Impact Crusher; Cone Crushers; Sand Maker ; Ball Mill; Raymond Mill; Differences And Applications Of Magnetic magnetic separation mineral dressing03/02/2021 General References Kolm, Oberteuffer, and Kelland, HighGradient Magnetic Separation, Sci Am, 233 5 , 4654 November 1975 Lawyer and Hopstock, Wet MagneticMagnetic Separation Mineral Processing Beyond Discovery

magnetic separation the mineral dressing

Mineral Dressing Test, Mineral Dressing Test Report Optimal mineral processing technology will be provided after various mineral processing tests including gravity concentration,ic separation, flotation, cyanide leaching and adsorption, bacterial oxidation, acid leaching and wet mineral processing, special mineral processing, dump leaching, tailings thickening and dry Mining : magnetic separation under mineral dressing Twitter; Facebook; Snapchat; Instagram; Medium; Please write your message here! We will send detail technical info and quotation to you as soon as possible! mineral processing metallurgy Britannica mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste magnetic separation under mineral dressingYantai Xinhai provides 5 kinds of mineral dressing solution including magnetic separation, flotation separation, gravity separation, tailings dry stacking and all sliming cyanidationProduction Line Xinhai