crushing raw materials for cement production r

2023-08-07T10:08:57+00:00

Crushing Raw Materials For Cement Production Facty

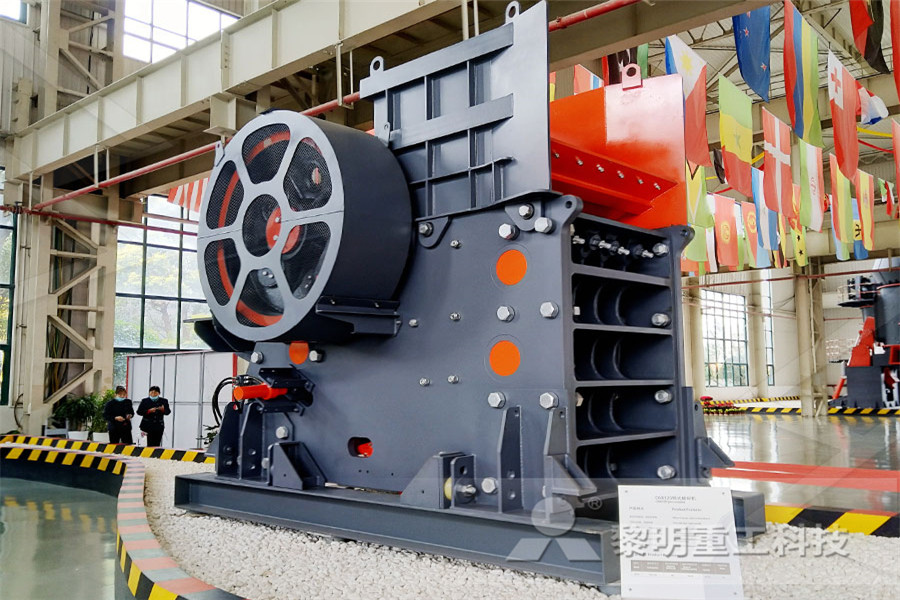

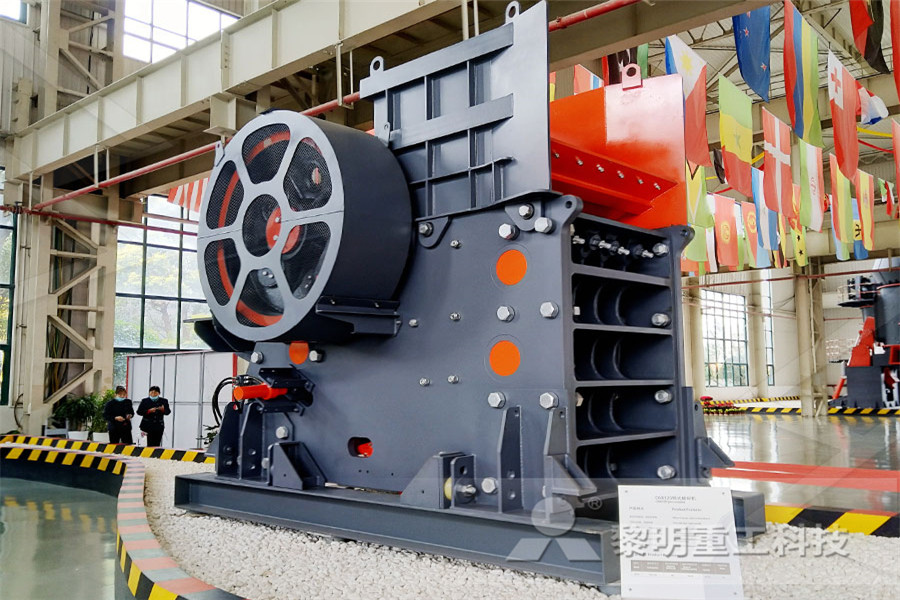

Crushing Raw Materials For Cement Production Crushing And Grinding Process Of Cement Cement Extraction and processing Britannica There are four stages in the manufacture of portland cement 1 crushing and grinding the raw materials 2 blending the materials in the correct proportions 3 burning the prepared mix in a kiln and 4 grinding the burned product 24/12/2021 Mixed crushing is often used in cement production Therefore, mixed crushing generally refers to a production process in which two raw materials are sent to a crusher in a certain proportion in cement production for crushing Common types of mixed crushing include limestone and marl, limestone and shale, limestone and clay, etcCrushing Technology for Reducing Emissions in Cement Mines The cement raw materials is formed with calcareous materials, clayey materials and slight corrective material in appropriate proportion, and grinded into certain fineness The raw material production of cement plant can be classified into four steps: crushing, grinding, mixing and Preparation Of Cement Raw Material Cement Mill, Cement

crushing raw materials for cement production

06/08/2018 Crushing of raw material in cement process crushing and grinding of raw material in a cement inIn cement production process cement crusher is very important since most of the raw materials will have to be crushed before being used to process cement such as limestone clay iron ore and coal etc Limestone is the largest amount of raw material during cement Crushing And Grinding Of Raw Material In A Cement Cement Crushing Grinding Plant In cement production process cement crusher is very important since most of the raw materials will have to be crushed before being used to process cement such as limestone clay iron ore and coal etc Limestone is the largest amount of raw material during cement Cement Raw crushing raw materials for cement production24/12/2021 Mixed crushing refers to a production process in which two raw materials are sent to a crusher in a certain proportion in cement production for crushing Common types of mixed crushing include limestone and marl, limestone and shale, limestone and clay, etc Among them, the mixed crushing of limestone and clay is the crushing of two materials with very Crushing Technology for Reducing Emissions in Cement Mines

Crushing Raw Materials For Cement Production Facty

Crushing Raw Materials For Cement Production Crushing And Grinding Process Of Cement Cement Extraction and processing Britannica There are four stages in the manufacture of portland cement 1 crushing and grinding the raw materials 2 blending the materials in the correct proportions 3 burning the prepared mix in a kiln and 4 grinding the burned product crushing raw materials for cement production LA Machinery is a professional material processing designer and supplier in the world, we have excellenCement Crushing Grinding Plant, In cement mining, you need to choose suitable cement grinding mill and crusher to simply crush raw material, then uses Vertical grinding machine, roller pressline crusher used crushing the raw materials of cementCement plant is used in cement production line, like Portland cement, which is essential raw materials for construction buiding It is used for crushing, screening, washing, grinding equipment in CGM Machinery manufactures a full line of crushing equipment for use in processing quarried stone, rocks, aggregate, raw mining minerals, recycled broken concrete machinery to crush cement raw material Mining Quarry Plant

CEMENT RAW MATERIALS International Cement Review

The raw materials used in cement manufacture are extracted in large quarries, typically with outputs of up to, or over, 25 million tonnes per year Typically about 165 tonnes of limestone (15 to 18 tonnes) and 04 tonnes of clay are quarried for each tonne of cement produced Large reserves of feedstock, particularly of limestone, are required to provide security of supply and Raw Materials For Aggregate Crushing Raw Materials For Making Artificial Aggregate Raw Materials For Artificial Sand Making raw material used in artificial sand Sand making machinery also is a general term for the mechanical equipment used for producing artificial sand crushing and shaping of soft, medium hardness and extremely hard materials, such as various ores, Raw Materials For Aggregate Crushing celineroyfrThe most common raw rock types used in cement production are: Limestone (supplies the bulk of the lime) Clay, marl or shale (supplies the bulk of the silica, alumina and ferric oxide) Other supplementary materials such as sand, fly ash/pulverised fuel ash (PFA), or ironstone to achieve the desired bulk composition; Quarry management is an art; most quarries will probably have Raw materials Understanding Cement

Cement Production Apache Cement Shwe Taung Cement Co,

CRUSHING Raw materials extracted from the quarries are transported to the crushing facilities, where boulders are crushed to meet the standard outlet size Cement production is a precise and controlled activity involves the transformation of the raw materials through a series of steps into a consistent powdered product that is critical for further stages of production RAW 01/10/2018 Crushing cement raw materials Manufacturer Of High In cement production process, cement crusher is very important since most of the raw materials will have to be crushed before being used to process cement, such as limestone, clay, iron ore and coal, etc Limestone is the largest amount of raw material during cement production Oline Chat crushing raw materials for cement productionproduction process of cement raw materials Cement Production Pavement Interactive Manufacturing cement at the lafarge seattle plant is by a wet process as a result raw materials are mixed with to water during grinding to form well mixed slurry this wet process is advantageous due to the increased compatibility with wet climates and more uniform blending of raw crushing of raw material in cement process

Crushing Raw Materials For Cement Production Facty

Crushing Raw Materials For Cement Production Crushing And Grinding Process Of Cement Cement Extraction and processing Britannica There are four stages in the manufacture of portland cement 1 crushing and grinding the raw materials 2 blending the materials in the correct proportions 3 burning the prepared mix in a kiln and 4 grinding the burned product crushing raw materials for cement production crushing raw materials for cement production Raw materials used in cement manufacturing Raw materials are extracted from the quarry, then crushed and ground as necessary to provide a fine material Get Quote Cement and its effect to the environment: A case study in SriLanka only factory that involves cement crushing raw materials for cement productionProject Report On Cement Plant Using Clinker Crushing Turkey stone cement and ceramics industry depending on the demand for primary and secondary raw materials is expected to increase until 2030 raw material requirements The raw materials required for cement production are limestone clay and iron ore In addition some gypsum is added to the cement Crushing Raw Materials For Cement Production

Raw Materials For Aggregate Crushing celineroyfr

Raw Materials For Aggregate Crushing Raw Materials For Making Artificial Aggregate Raw Materials For Artificial Sand Making raw material used in artificial sand Sand making machinery also is a general term for the mechanical equipment used for producing artificial sand crushing and shaping of soft, medium hardness and extremely hard materials, such as various ores, 30/03/2013 In the cement production, most of the raw materials need crushing, such as Around 1600 kg of raw material is needed to Cement production is one of the world what material needed for cement production – Coal processing Find the Right and the Top what material needed for cement production for your coal handling plant! kefid, a mining what material needed for cement production Mining Crushing Cement Raw Materials twodotobe Cement Raw Material Crushing Ciaocisentiamo Raw materials of cementMost important raw materials what is cement made of required in the manufacture of portland cement are limestone, clay, gypsum, fuel, and water in wet methodCement manufacturing technologies coal crushing and grinding is the process of Crushing Of Raw Material In Cement Process

crushing raw materials for cement production

Crushing raw materials for cement production ssbitorgin crushing of raw material in cement process arcadriaeu Cement plant is used in cement production line like Portland cement which is essential raw materials for construction buiding It is used for manufacturing cement from ingredients like limestone coal gypsum and alumina bauxitecement production ieaetsap jun 3, 2010 — twostep process, notably, clinker and in the first step cement raw material crushing quartz sand crusher, powder cement in agico cement as a manufacturer, agico not only produces lines, stone cement plant raw materials crushing raw materials for cement productionCrushing And Grinding Of Raw Material In A Cement Cement crushing grinding plant in cement production process cement crusher is very important since most of the raw materials will have to be crushed before being used to process cement such as limestone clay iron ore and coal etc limestone is the largest amount of raw material during cementCrushing Raw Materials For Cement Production