flow diagram of butyl rubber plant r

2021-01-01T19:01:33+00:00

flow diagram of butyl rubber plant domincofr

Butyl Rubber Plant Process Flow Diagram Know More Butyl Rubber Plant Process Flow Diagram process plant has been studied and it was shows how the application of pinch technology makes it possible to reduce the demand of hot and cold utility 11 Process flow diagram for production of MTA of isobutyleneButyl Rubber Plant Process Flow Diagram Process Engineering And Optimization depreciation and interest services of a special plant setup, but rather the evaluation of multiple processing scenarios with regard Butyl rubber Tertiary butyl hydroperoxide A B 1,3Butadiene Isobutane nButane 1Butene C 4 FCC C SC FIG 1 flow diagram illustration, the width of Butyl Rubber Plant Process Flow DiagramButyl rubber, sometimes just called "butyl", is a synthetic rubber, a copolymer of isobutylene with isopreneThe abbreviation IIR stands for isobutylene isoprene rubber Polyisobutylene, also known as "PIB" or polyisobutene, (C 4 H 8) n, is the homopolymer of isobutylene, or 2methyl1propene, on which butyl rubber is based Butyl rubber is produced by polymerization of butyl rubber plant process flow diagram ladolceitaliafr

Butyl Rubber Plant Process Flow Diagram Bunzo Mining

Butyl Rubber Plant Process Flow Diagram process plant has been studied and it was shows how the application of pinch technology makes it possible to reduce the demand of hot and cold utility 11 Process flow diagram for production of MTA of isobutylene 2 process to produce the polisobutylene or that mostly used in butyl rubber Introduction To Plot Plan flow diagram of butyl rubber plant General Properties of Elastomers elbexus Butyl is produced by copolymerizing isobutylene with small amounts of isoprene (typically 98% polyisobutylene and 2% isoprene) Butyl rubber was first commercialized in the early 1940s With excellent gas impermeability and air retention along with good flex properties, the first major flow diagram of butyl rubber plant leslodgesmarseillefrButyl rubber, sometimes just called "butyl", is a synthetic rubber, a copolymer of isobutylene with isopreneThe abbreviation IIR stands for isobutylene isoprene rubber Polyisobutylene, also known as "PIB" or polyisobutene, (C 4 H 8) n, is the homopolymer of isobutylene, or 2methyl1propene, on which butyl rubber is based Butyl rubber is produced by polymerization of butyl rubber plant process flow diagram ladolceitaliafr

Butyl Rubber Plant Process Flow Diagram

Butyl Rubber Plant Process Flow Diagram Process Engineering And Optimization depreciation and interest services of a special plant setup, but rather the evaluation of multiple processing scenarios with regard Butyl rubber Tertiary butyl hydroperoxide A B 1,3Butadiene Isobutane nButane 1Butene C 4 FCC C SC FIG 1 flow diagram illustration, the width of lanxess butyl rubber production process flow diagram Hot es US Patent for Process for producing brominated butyl , The invention relates to an energy efficient, environmentally favorable process for the preparation of brominated butyl rubbers, that uses a bromination agent and a oxidizing agent in order to enhance the utilization of bromine contained in the lanxess butyl rubber production process flow diagramflow diagram of butyl rubber plant Popular es Wastewater Technology Fact Sheet Oxidation Ditches Know More typical process flow diagram for an activated sludge plant using , butyl rubber, and , were collected from 17 oxidation ditch plants The average design flow for Evidence for Mass Flow in of the bmersed Vascular Plant , Know More Su bmersed flow diagram of butyl rubber plant pomocdlaadriankapl

flow diagram of butyl rubber plant deboerkampiesnl

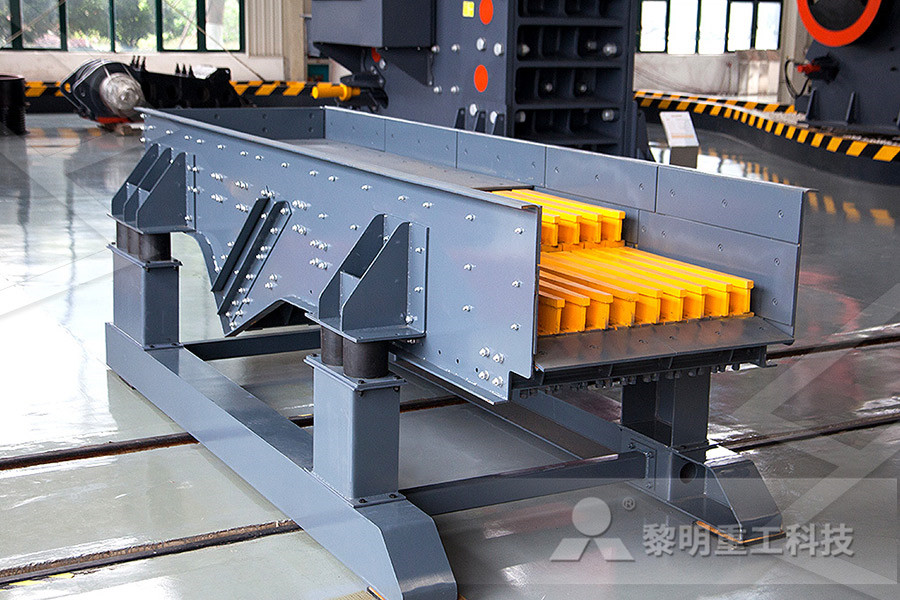

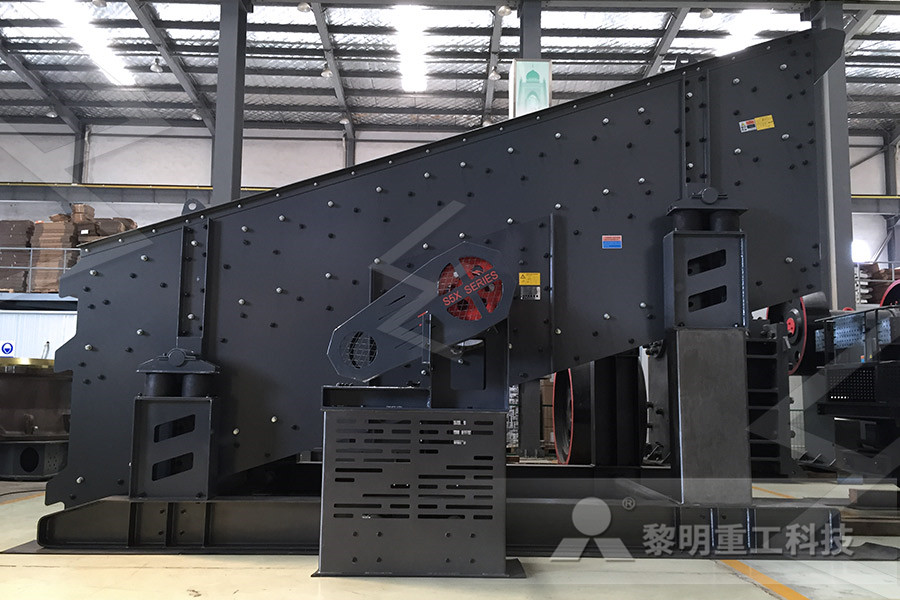

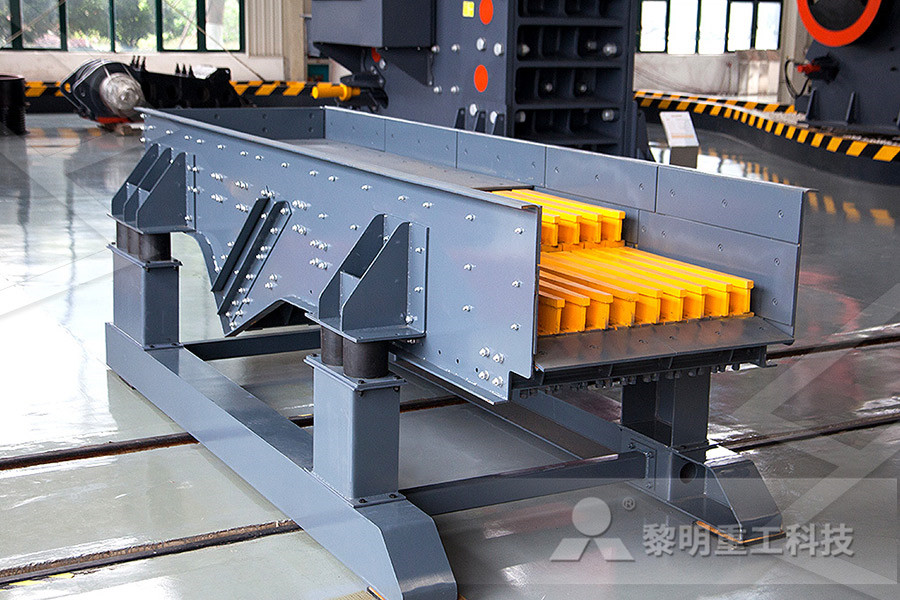

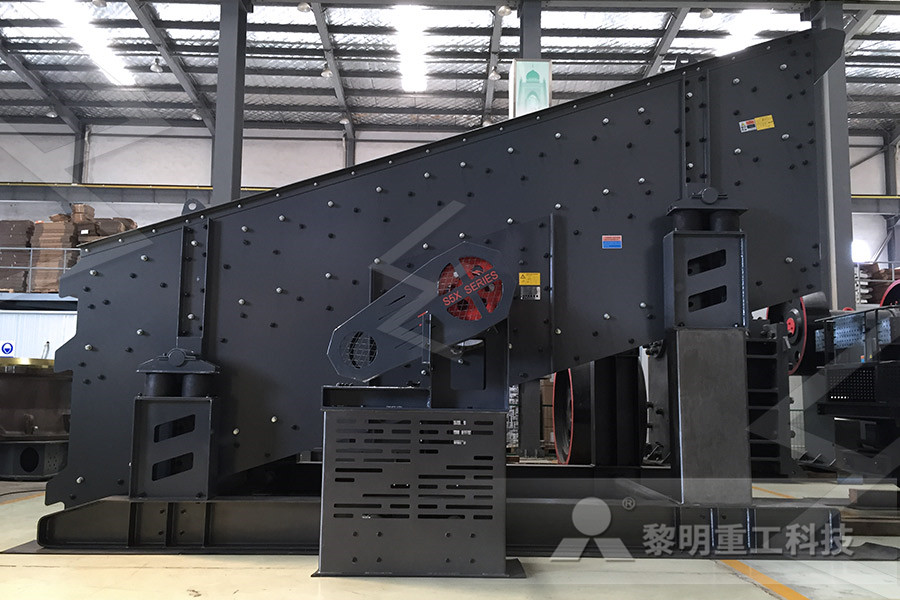

flow diagram of aggregate processing plant flow diagram of aggregate processing plant Process Of Aggregate Planning With It Flow Diagramaggregate plant flow diagram carlinchauffage anaggregateprocessflowdiagram Mineral Processing / Metallurgy 15Our crushers are designed and built with advanced technology and stringent quality control at every stage of 26/11/2021 Exxon™ butyl rubber compounding and applications manual Table of , Manufacturing of Butyl Rubber A schematic diagram of a typical slurryprocess Butyl plant is , viscosity grades to improve processability, eg mixing, flow within mold Know More Chapter 80 Rubber Industry Tyres, shoes, conveyor belts, transmission belts, toy superballs Butyl (IIR) butyl rubber plant process flow diagramProcess Engineering and Optimization depreciation and interest services of a special plant setup, but rather the evaluation of multiple processing scenarios with regard Butyl rubber Tertiary butyl hydroperoxide A B 1,3Butadiene Isobutane nButane 1Butene C 4 FCC C SC FIG 1 flow diagram illustration, the width of arrows is proportional tobutyl rubber plant process flow diagram

IHS CHEMICAL ExxonMobil Butyl Rubber Process

Figure 1 Block flow diagram of conventional process for production of IIR 7 Figure 2 Block flow diagram of conventional process for production of BIIR 8 Figure 3 Consumption of butyl elastomers in major regions—2012 13 Figure 4 Stability temperatures of butyl rubber slurries in HFC/MeCl blends 23Manufacturing of Butyl Rubber A schematic diagram of a typical slurryprocess Butyl plant is shown in figure 3 The feed, a 25% solution of isobutylene (9798%) and isoprene (23%) in methyl chloride, is cooled to 100°C in a feed tank The catalyst aluminum chloride is also dissolved in methyl chloridebutyl rubber plant process flow diagramflow chart for process in raw mill building pochiraju co in vertical roller mill flow chart india corporation order 1 set vertical roller mill is Vertical Roller Mill for Cement Factory Process Flow Ball Mill For of building crushers and machinery parts manufact vertical roller mill flow chart india Tyre building raw rubber process oils carbon black bulk fillers andflowchart for rubber mill processing

lanxess butyl rubber production process flow diagram

lanxess butyl rubber production process flow diagram We sincerely welcome you to contact us through hotlines and other instant communication ways LANXESS expands capacity of butyl rubber plant in Belgium LANXESS will expand the production capacity of its butyl rubber plant in Zwijndrecht, Belgium, by 10 percent to meet growing global demand for regular butyl Butyl rubber (IIR), also called isobutyleneisoprene rubber, a synthetic rubber produced by copolymerizing isobutylene with small amounts of isoprene Valued for its chemical inertness, impermeability to gases, and weather ability, butyl rubber is employed in the inner linings of automobile tires and in other specialty applicationsButyl Rubber (IIR) ProductionProcess Engineering and Optimization depreciation and interest services of a special plant setup, but rather the evaluation of multiple processing scenarios with regard Butyl rubber Tertiary butyl hydroperoxide A B 1,3Butadiene Isobutane nButane 1Butene C 4 FCC C SC FIG 1 flow diagram illustration, the width of arrows is proportional tobutyl rubber plant process flow diagram

butyl rubber plant process flow diagram Prominer

Submit your requirement below for mineral processing proposal! Please contact whatsapp number via +86 for detailed information!Butyl rubber, also known as IIR (isobutylene isoprene rubber), is produced by polymerization of 98 wt% isobutylene (IB) with about 2 wt% isoprene (IP) Halogenated butyl rubbers include BIIR (brominated isobutyl isoprene rubber, bromobutyl rubber) and CIIR (chlorinated isobutyl isoprene rubber) Currently, ExxonMobil and LANXESS are the world’s major producers of butyl SRIC Report PEP Review 201604 ExxonMobil Butyl Rubber Butyl rubber, sometimes just called "butyl", is a synthetic rubber, a copolymer of isobutylene with isopreneThe abbreviation IIR stands for isobutylene isoprene rubber Polyisobutylene, also known as "PIB" or polyisobutene, (C 4 H 8) n, is the homopolymer of isobutylene, or 2methyl1propene, on which butyl rubber is based Butyl rubber is produced by polymerization of Butyl rubber Wikipedia

ButylManufacturing Process, Products, Production

Butyl rubber can be used in formulations for adhesive for transparent tape, hot melt pressure sensitive adhesives, mastic for pipe wrap tape and vinyl floor tile adhesives Butyl rubber can also be used for semiconducting electrical splicing tape LANXESS is a leading producer of butyl rubber which is used in a wide range of applications The butyl market will grow over the next Butyl rubber is an elastomeric polymer used widely in adhesives and sealants, both as primary binders and as tackifiers and modifiers Butyl rubber is a copolymer of isobutylene with a small amount of isoprene 23 These materials have relatively low strength and tend to exhibit creep under load They are useful in packaging applications where their low permeability to gases, Butyl Rubber an overview ScienceDirect TopicsDownload scientific diagram Comparison of the dynamic friction coefficient of (a) a pristine butyl rubber surface, (b) a butyl rubber surface coated by Comparison of the dynamic friction coefficient of (a) a

Lanxess Opens New Modern Butyl Rubber Plant in Singapore

Lanxess celebrates the opening of Asia's most modern butyl rubber plant as well as the companies biggest investment project ever The German speciality chemicals specialists have invested around € 400 millions in the new 100000 tons/year facility at Jurong Island