gold leaching processes mill r

2023-03-02T15:03:29+00:00

Gold Metallurgy and Leaching Process

24/06/2015 Leaching is a heterogeneous process, involving three reaction steps: Diffusion of solvent through the pores in the solid particles, and of the dissolved substance outwards after solution Chemical solution at the reaction site in the particle Transport of the dissolved substance in the solvent away from the particle surface02/01/2013 Carbonin leach (CIL) is a simultaneous leach and absorption process The simultaneous leach and absorption phases of the CIL process were developed for processing gold ores that contain pregrobbing materials such as natural absorptive carbon These reduce the gold yield by attracting gold meant for the activated carbonGold CIL CIP Gold Leaching Process Explained CCD27/03/2020 Gold heap leaching process is often used to develop smallsized gold deposits or lowgrade ore (13 g/t), or those small lowgrade gold mines that cannot be developed and utilized by conventional methods The gold heapleaching field has little requirement in terrain conditions, and can be adapted to local conditionsUltimate Guide of Gold Heap Leaching Process

Heap Leaching Gold Extraction Process – ballmillgrinder

Heap Leaching System: A heap leaching system is set on the ore heap, and the leaching solution infiltrates into the ore heap and reacts with gold The gold containing solution (precious liquid) exudes from the bottom of the ore heap, flows into the precious liquid pool, and is pumped into the adsorption column through the precious liquid pump29/02/2016 The processing of gold ores has traditionally made use of conventional crushing and grinding circuits In each case where gold is formed either as coarse native particles or in coarse grained sulphides, it is recovered by gravimetry concentration in the in the comminution circuit in addition to recovery of finer values by leachingGold Extraction Recovery Processes07/09/2017 At current gold prices this is worth about US$600 Both smelter treatment charges and oxidation or bioleach costs are at least $200/t of concentrate and payables/recovery in the 90% range, so a minimum GSR for effective downstream processing is around 05Gold processing 101 Mining Magazine

Gold Processing,Extraction,Smelting Plant Design

These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient process designs27/03/2020 In the shortterm gold heap leaching process, the ore is usually crushed to less than 20 mm When processing goldbearing quartz veins, it is often crushed to less than 6 mm The crushed ore heap is leached on a Ultimate Guide of Gold Heap Leaching Process20/12/2021 Step5 The entire leaching process should be supplemented with cyanide and lime water in an appropriate amount according to the specific situation to supplement the consumption of cyanide and maintain the pH value of the leaching solution at 1011 The leaching cycle is generally 10~15 days If the gold content of the raw ore is high or the temperature is too low, it 9 Important Processes of Pool Leaching

4 Factors Affecting Gold VAT Leaching Process

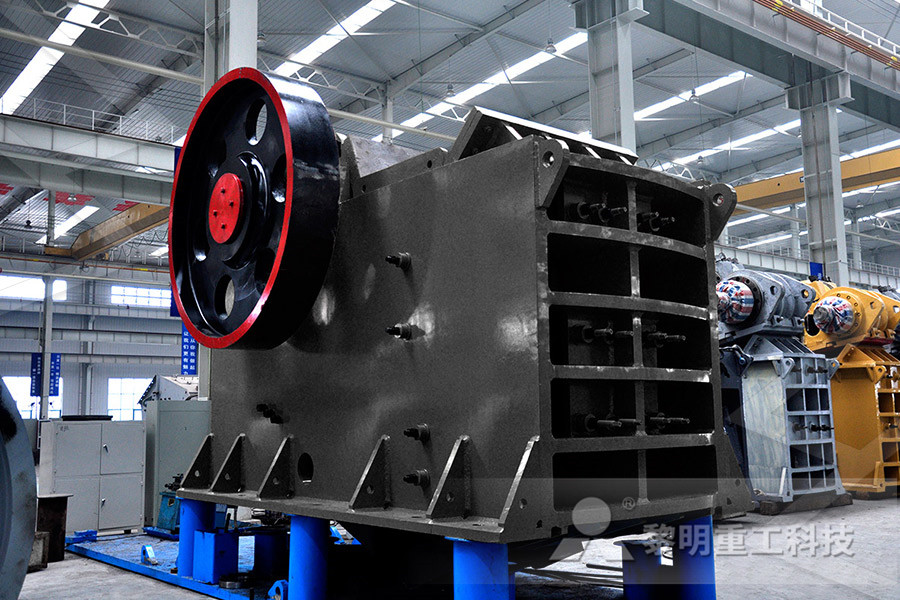

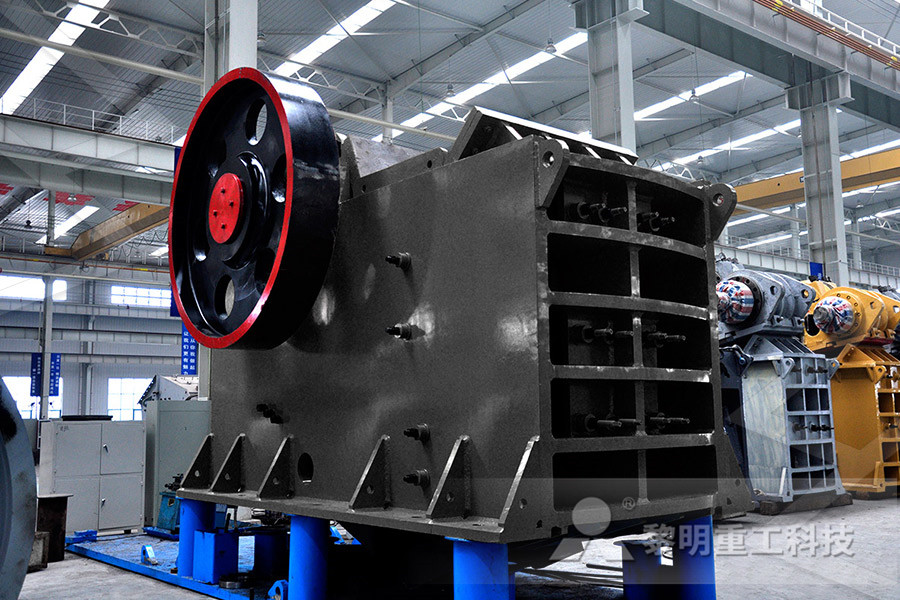

05/06/2020 Gold vat leaching process is currently widely used in smallscale gold mines, because of a series of advantages including high recovery rate, strong adaptability to ore, low cost and simple process The basic principle is first to leach the gold from the ore with cyanide solution containing oxygen, and then to extract the gold from the leaching solution with zinc leaching process of gold has been outlined In the present study, an attempt is made to assess the feasibility of ammoniacal thiosulphate leaching of Gold Leaching Equipment, Gold Leaching Equipment Alibaba Gold Leaching Equipment, Buy Various High Quality Gold Leaching Equipment Products from Global Gold Leaching Equipment Suppliers and Gold Gold Leaching Process brindedetentefrleaching gold processes Ball Mill Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuitsleaching gold processes asiacrusher

What Are The Factors Affecting Gold Leaching?

21/02/2020 Gold is not active metals, in the process of cyanide leaching, gold can be under the action of oxygen and cyanide complexation reaction (CN), produce a watersoluble melamine aurous acid salt complex [Au (CN) 2], so the cyanide agent is a key factor determine gold dissolved, in general, to ensure that a certain amount of free cyanide in the pulp, to margin Additional advantages of lime addition include decomposition of bicarbonates in mill water, improvement in settling rate in counter current decantation thickeners and improvement in extraction rates for certain types of ores such as tellurides and ruby silver Heap Leaching Heap leaching was introduced in the 1970’s as a means to drastically reduce gold recovery costs (PDF) Gold Extraction and Recovery Processes For Internal 01/10/2009 The millleaching process was simple, inexpensive and well accepted by the local miners as it can be implemented without any additional investment in new equipment Local miners were pleased to see more gold in their hands in reasonable short time (24 h) The main problem in introducing the millleaching process is the organization of miners Mill leaching: a viable substitute for mercury

Gold cyanidation Wikipedia

Gold cyanidation (also known as the cyanide process or the MacArthurForrest process) is a hydrometallurgical technique for extracting gold from lowgrade ore by converting the gold to a watersoluble coordination complexIt is the most commonly used leaching process for gold extraction Production of reagents for mineral processing to recover gold, copper, zinc and 10/10/2019 All the industrially applied gold leaching methods (historical chlorine gas based leaching, dominating stateoftheart cyanide gold leaching, processes at precious metals plants) suffer from the characteristics related to aggressive and even toxic leaching media and high chemical consumption This study targets environmentally sound cyanidefree gold Cyanidefree gold leaching in exceptionally mild chloride Gold Leaching CIL process is suitable for the treatment of oxidized gold ore with low sulfur content and mud content It is unsuitable for the gold ore with highgrade silver Generally, the proportion of gold and silver should not Gold Leaching Carbon in Leach JXSC Machine

Gold leaching plant (GOLD CIL PLANT) Pineer Mining Machinery

21/04/2019 PINEEER GOLD LEACHING PLANT (CIL) Achieve optimal gold recovery with minimal impact on the environment The Pineer gold cyanide leaching process enables sustainable and costeffective gold recovery >90% Comes from one supplier, responsible for the whole package Provides mechanical and performance guarantees for the entire plant unit, 20/10/2014 Leaching gold with a cyanide solution remains the most widely used hydrometallurgical process for the extraction of gold from ores and concentrates Despite the difficulties and hazards of working with cyanide, no other process has yet been proven to be an economic viable alternative A paper published by L Elsner in 1846 first correctly identified the The Metallurgy of Cyanide Gold Leaching – An Introduction Leaching at a higher pH value can also be beneficial in improving silver extraction and stabilizing silver in solution In addition, operating at a higher pH value favors the hydrolysis of the thiosulfate degradation products such as tetrathionate, which has been attributed to gold and silver loss during leaching (Aylmore et al, 2014) However Gold Extraction an overview ScienceDirect Topics

Gold beneficiation guide,processes in rock gold mines

27/08/2020 The gold selection process by carbon slurry method (CIP method and CIL method) is to put activated carbon into the cyanide slurry, adsorb the dissolved gold on the activated carbon, and then extract gold from the activated carbon, mainly including leaching raw material preparation, stirring leaching and countercurrent Carbon adsorption, goldloaded carbon mill began processing highgrade gold and silver ore from open pit and underground mines using a new leaching tech nology called the CANMET Kupol mill leach operation in 20080917/06/2020 The cyanidation process of gold extraction or the use of cyanide is the most common leaching process, used in the extraction of gold from its ores Some countries do not approve of this method of gold extraction because of the poisonous nature of the cyanide Steps to extract gold by cyanidation process: The process of extracting gold by cyanidation How gold is extracted by Cyanidation Process Refresh Science

FLOWSHEET DEVELOPMENT FOR GOLD OREBODIES SGS

mill, agitatedtank leaching operations, gold is extracted directly from the leached pulp in either a carboninleach (CIL), or a carboninpulp (CIP) plant In both these cases, the coarse granules of activated carbon are mechanically mixed with the pulp in an adsorption tank, and goldloaded carbon granules are separated from golddepleted pulps by screening The screening While the leaching process continues in these tanks, the primary objective is to remove the gold and silver from the solution To achieve this, carbon is fed through the tanks (4) and the gold and silver adsorbs (attaches) to the carbon granules Carbon is heated to 600 degrees C and fed into the circuit in the opposite direction to the slurry flow, moving from the last adsorption tank to Ore Processing OceanaGold Waihi OperationProcess Cyanide can be used to extract gold, either in a controlled mill environment, or more crudely on rock piles in the open Cyanide "vat leaching" mixes finely crushed ore with a cyanide salt in water The cyanide binds to the gold ions, and makes them soluble in water, thereby allowing separation from the rockGold Cyanidation