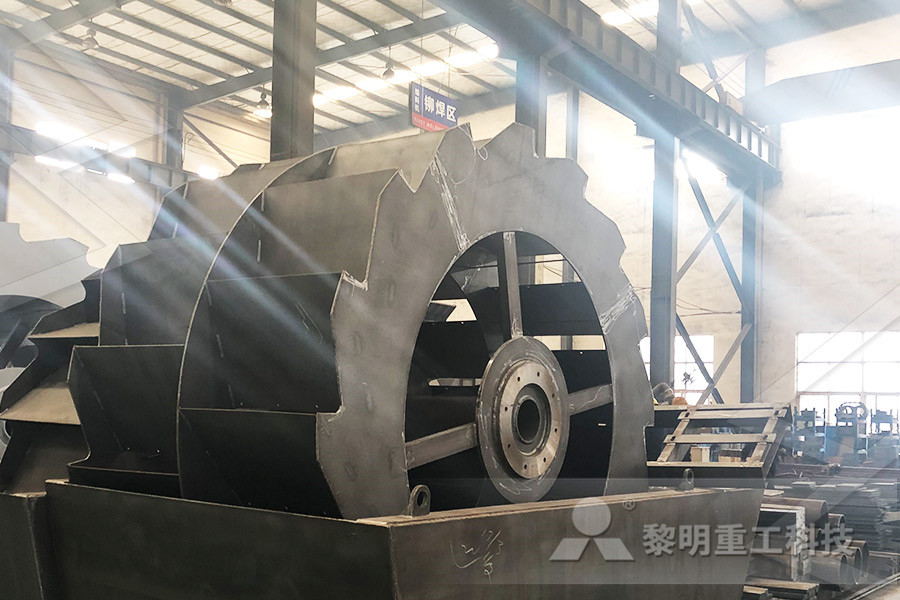

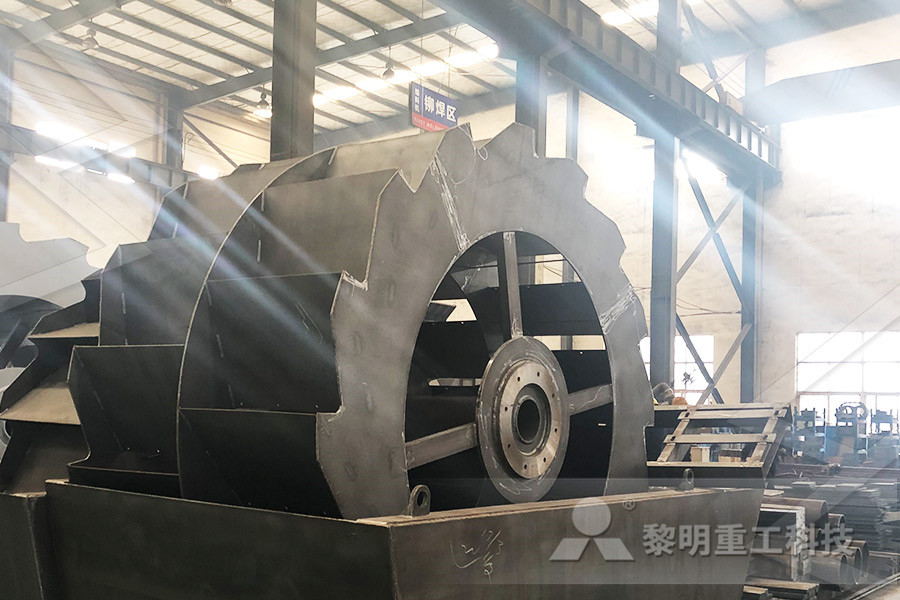

h capacity mineral equipment of spiral separator

2021-04-20T04:04:24+00:00

High capacity gravity separators a review of current

High Capacity Mineral Spirals The recently developed high capacity MG2 model spiral separator was designed primarily for a roughing duty with the proposed advantages of Greater overall feed capacity for a given plant space resulting in reduced capital expenditure Simplified feed distribution and product launderingcapacities of the spiral concentrators range between 1 and 3 t/h dry solids and recently in excess of 7 t/h in the case of high capacity spiral concentrators (PDF) Case study: High capacity spiral Mineral Processing Equipment Spiral Separator, Find Details about Spiral Chute, Mining Machine from Mineral Processing Equipment Spiral Separator Jiangxi Gandong Mining Equipment Machinery ManufacturerMineral Processing Equipment Spiral Separator China

Spiral Separators Mineral Processing

The spiral chute mainly uses the inertial centrifugal force generated by the minerals of different densities in the spiral rotation to achieve the separation of light and heavy minerals Because of its simple equipment structure, low power consumption, and large processing capacity, it is widely used in the gravity separation processSpiral Chute Separator Model: glasssteel spiral chute Feed size:03002mm Production Capacity: 015~8t/h Application range: Applicable to sort iron ore, ilmenite, chromite, zirconite, rutile, tungsten ore, tin ore, tantalumniobium ore Spiral Chute Separator Gravity Separation The spiral separator is the best gravity concentrating equipment, especially for concentrating sand ore in seashore and riverside It is made of the fiberglass, lined with wearresistant polyurethane and covered with corundum cover It has advantages such as lightweight, moisture proof, antirust and corrosion, noiseless, very suitable for the different feeding particle Spiral Separator Spiral chute Spiral Classifier

Gravity Separation Mineral Technologies

The fine mineral spiral series is used for fine feed with particles in the range of 30150 microns: WW Series: Utilises wash water addition for enhanced grade control in specific applications (ie iron ore, mineral sand) HC Series: Spiral concentrator or spiral chute for gravity method mineral plant, larger capacity, no noise, 24 hours working without stop Mineral Equipment Spiral Concentrator Spiral Concentrator Marvin June 18, 2015 December 13, 2018 running the output of one spiral separator (often, a third, intermediate, cut) through a second Spiral Concentrator Henan Deya Machinery Co, Ltd Spiral concentrator is our company’s concentrating experienced scientific product, which is the best concentrating equipment, especially for concentrating sand ore in beach, riverside, seashore and stream The product is made of the fiberglass lined with wearresistant resin and emery It is the domestic advanced level, the new highly Spiral concentrator, spiral chutes, spiral separators

Gravity Spiral Concentrator Working Principle

A capacity of 38 tons per spiral was obtained in the 1000ton per 24 hr Oregon plant operating on about a minus 40mesh feed and in the 5000ton plant recently installed near Jacksonville to concentrate ilmenite 174 roughing, Our spiral separators for heavy minerals, including iron ore, chrome, mineral sands and other highdensity minerals, separate particles in the size range 15 to 004 mm We have 3turn, 5turn and 8turn spirals with high, medium and lowgradient profiles Our highcapacity spiral separator (the HX series) provides a perstart tonnage rating Spiral Separator Multotec Mineral ProcessingCustomers can avail from us Sand Spiral Separator in single, twin, triple or quadruple starts Designed in 600mm diameter, our Sand Spiral Separator features seven turn units Tonnage rating per start is 50tph depending on MINERAL SPIRAL SEPARATOR Sand Spiral

Spiral SeparatorClassifiersScrew classifier

Product Introduction The spiral separator is a piece of important beneficiation equipment in mineral processing The spiral separator is applied for iron, tin, tungsten, tantalum, niobium, gold, coal, zircon and other metal, Working Principle Spiral Separators, which are also called Spiral Concentrators, are gravity devices that separate minerals of different specific gravity according to their relative movement in response to gravity, centrifugal force and other forces in the fluid medium The heavy frictional forces slow their velocity As a result, faster particles higher up in the flowSpiral Separator Spiral Concentrator GTEKMineral Spiral Concentrators Separation of fine heavy minerals has been made easier with Multotec’s ranges of mineral spiral concentrators Our gravity concentration products separate fine heavy mineral sizes from 15 mm to 004 mm and are ideal for iron ore, chrome, mineral sands and high density ores Available in the HX3, HX5 and SC Mineral Spiral Concentrators Multotec

Gravity Separation Mineral Technologies

The fine mineral spiral series is used for fine feed with particles in the range of 30150 microns: WW Series: Utilises wash water addition for enhanced grade control in specific applications (ie iron ore, mineral sand) HC Series: Spiral concentrator is our company’s concentrating experienced scientific product, which is the best concentrating equipment, especially for concentrating sand ore in beach, riverside, seashore and stream The product is made of the fiberglass lined with wearresistant resin and emery It is the domestic advanced level, the new highly Spiral concentrator, spiral chutes, spiral separators A gravity separation equipment of separation different weight mineral by inertial centrifugal force pulp produced in helix turning motion Capacity 015~16t/h Product Improvement There are 3 kinds of chute for user to choose, glass steel chute, Xinhai wearresistant rubber liner, polyurethane rubber linerGravity Separation Equipment, Gravity Separator for Sale

A Review of Spiral Technology for Fine Gravity

capacity viz at 60% efficiency and 30% mass to concentrate the MG4 indicates a capacity of 35 t/h compared to 75 t/h for the HCP spiral Additional feed types are currently being sourced to quantify the performance of this new spiral type for use in other fine gravity separation duties REFERENCESSYSTEMS ALICOCO Mineral Technologies manufacture a full range of mineral processing Spiral separator s, working in close association with other equipment manufacturers to provide tailored mineral process solutions ALICOCO systems are environmentally responsible, in that there are no chemicals used in the processing and tails remediation is a part of water reharvesting广州铭谦选矿设备有限公司 ALICOCO MINERAL capacities of the spiral concentrators range between 1 and 3 t/h dry solids and recently in excess of 7 t/h in the case of high capacity spiral concentrators when treating typical heavy (PDF) Case study: High capacity spiral

Mineral Spiral Concentrators Multotec

Mineral Spiral Concentrators Separation of fine heavy minerals has been made easier with Multotec’s ranges of mineral spiral concentrators Our gravity concentration products separate fine heavy mineral sizes from 15 mm to 004 mm and are ideal for iron ore, chrome, mineral sands and high density ores Available in the HX3, HX5 and SC Spiral Chute Type : Mineral Separation Capacity : 0245L/h1 Application field : This machine is applicable for selecting materials with size 03002mm, such as iron ore, ilmenite, chromite, pyrite, azorite, rutile ( * Please Spiral ChuteSpiral Chute SeperatorSpiral Spiral concentrator or spiral chute for gravity method mineral plant, larger capacity, no noise, 24 hours working without stop Mineral Equipment Spiral Concentrator Spiral Concentrator Marvin June 18, 2015 December 13, 2018 running the output of one spiral separator (often, a third, intermediate, cut) through a second Spiral Concentrator Henan Deya Machinery Co, Ltd

China The Spiral Separator for Separation of Minerals

Which is also called table concentrator is a mine separation device for fine minerals working by gravity They are effectAbout China The Spiral Separator for Separation of Minerals FOB price, Payment, OEM information, wholesale Mineral Separator from china companies factories on topchinasupplier13534 Spiral Concentrator The spiral concentrator is a modern highcapacity and lowcost device It is developed for concentration of lowgrade ores and industrial minerals in slurry form It works on a combination of solid particle density and its hydrodynamic dragging propertiesSpiral (Concentrators) an overview ScienceDirect TopicsMultotecdesigned spiral concentrators are used across the world in coal, gold, iron ore, mineral sands, platinum and chrome processing plants and other minerals As a turnkey supplier of gravity concentration equipment across the Spiral Concentrator Multotec Multotec

gravity spiral concentrators,spiral chutes,spiral

spiral concentrator,gold spiral concentrator,gravity spiral concentrator,spiral concentrator for sale,fiberglass spiral chute,spiral chute layout,gravity spiral chute,spiral chute separator,mineral spiral SYSTEMS ALICOCO Mineral Technologies manufacture a full range of mineral processing Spiral separator s, working in close association with other equipment manufacturers to provide tailored mineral process solutions ALICOCO systems are environmentally responsible, in that there are no chemicals used in the processing and tails remediation is a part of water reharvesting广州铭谦选矿设备有限公司 ALICOCO MINERAL A gravity separation equipment of separation different weight mineral by inertial centrifugal force pulp produced in helix turning motion Capacity 015~16t/h Product Improvement There are 3 kinds of chute for user to choose, glass steel chute, Xinhai wearresistant rubber liner, polyurethane rubber linerGravity Separation Equipment, Gravity Separator for Sale