Hammer Mill Pellet Mill r

2021-06-12T04:06:35+00:00

Hammer Mill Make Wood Pellets and Biomass Pellets

Hammer Mill As the pellet mill can only process the raw materials with a diameter lower than 5mm, before the pelletizing process takes part in a pellet plant, the raw materials such as straw, bark, branches, corn stalk, need to be resized17/04/2018 Pellet Mills for Biomass Easy to use, with an antivibration body, Graf Equipment pellet mills for wood and biomass are robust and durable With capacities up to 5 TPH, easy to change dies, and precision engineering, these customconfigured machines p romise efficiency, reliability, and superior pellet qualityPellet Mills for Biomass Schutte HammermillHammer Mills Our range of hammer mills are industrial quality and are designed to compliment our range of pellet mills From 75kw up to 30 kw hammer mills with various screen sizes and integrated dust collection and metal capturing if required grinding equipment Please for specifications Hops Hammer Mill View Brochure Vertical Hammer MillHammer Mills For Sale in USA Canada North America

Pelletizing Equipment Schutte Hammermill

Shimming your hammer mill; News; Contact Us; Pelletizing Equipment Showing all 9 results Direct Drive Pellet Mills for Biomass Read more; Hygieniser Read more; Pellet Coolers Read more; Pellet Crumblers Read more; Pellet Mill Dies and Roll Shells Read more; Pellet Mills for Biomass Read more; Pellet Mills for Feed and Grain Read more; Pellet Sieve Read more; PelletMasters Hammer Mills Electric, Gasoline, and Diesel Give us a call, we are here to help Products are intended for use with animal feed, fertilizer, and fuel production, but are not in compliance with food grade for human consumption unless otherwise specified in the product description Packaging and DeliveryHammer Mills Pellet Mastersand receive 10% off the cost of a Hammer Mill PelletMasters Pellet Mills for Wood All PelletMasters Pellet Mills suitable for wood will also produce pellets from softer materials, at a slightly lower production rate than a pellet mill designed for feed and fertilizerPelletMasters Pellet Mills, Hammer Mills, and Grinders

Best Sell Small Combine Hammer Mill and Pellet Mill for

The hammer mill is used to crush the raw material into powder size prior to entering the pellet mill The powder is then transported directly to the pellet mill via the Cyclone where dust and raw material is separated and pellets are produced It can work better with soft wood and materials with small diameter (less than 50mm)As the pellet mill can only process the raw materials with a diameter lower than 5mm, before the pelletizing process takes part in a pellet plant, the raw materials such as straw, bark, branches, corn stalk, need to be resized In that case, Hammer Mill Make Wood Pellets and Biomass Pellets17/04/2018 The robust and reliable pellet mills from Graf Equipment are ideal for wood and biomass pelletizing applications These mills are constructed of stainless steel and characterized by ease of use and maintenance With Pellet Mills for Biomass Schutte Hammermill

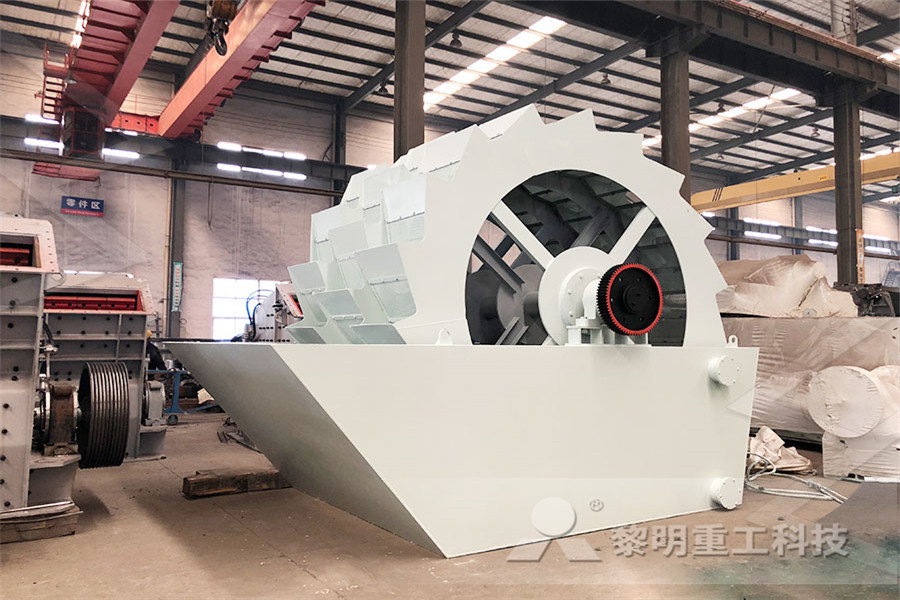

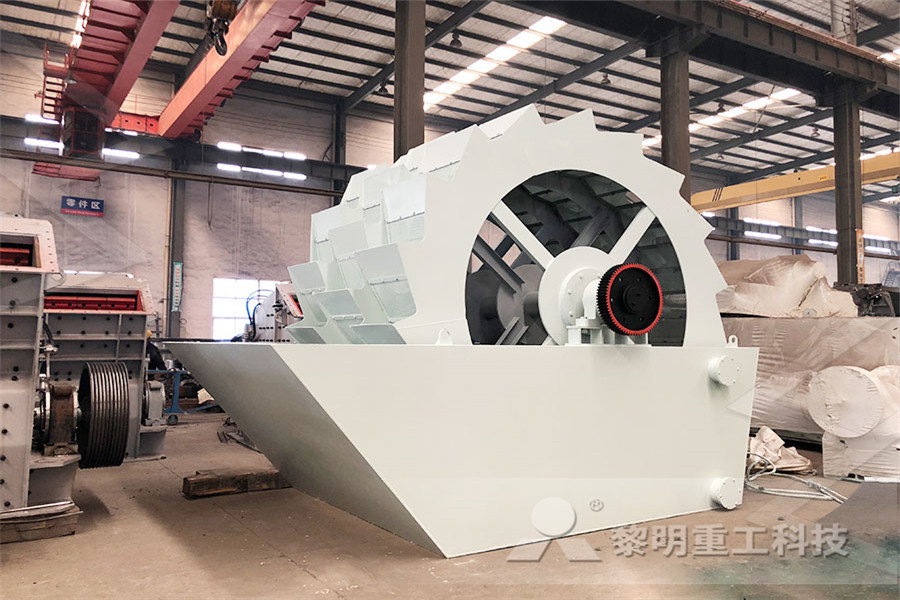

Hammer Mill for Biomass Pellet Plant

Hammer Mill The FSPZ hammer mill can pulverize such granule materials as corns, sorghum, various wheats, beans and rice dregs for biomass pellet plant, on top of that, it can also apply to sectors as chemical industry, foods and Hammer Mill for Wood Feed Pellet Processing Hammer mill, also called crusher machine, is the most commonly used auxiliary equipment in wood pellet production line or animal feed pellet mill, since not all raw materials have exactly the right size (below 3mm) for pelletizingUsually it can process various biomasses like corn, corn stalk, peanut shell, grass, Hammer Mill for Biomass Pellet Production saleWood Pellet Hammer Mill (DG series) The wood pellet hammer mill is a multifunctional crusher whose purpose is to shred or crush aggregate material into smaller pieces by the repeated blows of little hammers It can process different kinds of materials, like all kinds of biological stalks ( corn stalk, wheat straw, cotton stalk), rice straw Hammer mill for wood pellets (DG series) Woodpelletmaker

Hammer Mill for Feed, Biomass and Wood Pellet Plant Tear

Hammer Mill for Feed, Biomass and Wood Pellet Plant Tear Drop Design, heavy duty hammer mill, Dynamically balanced Rotor, Wood Chips To Sawdust grinding for Wood, Biomass, Feed Pellet Production Plant, suitable for wet and dry wood, final output of 10mm to 80mm, 400hp motor, vibration sensor with heavy duty bearing pedestals, with easy opening doors for quick Pellet mill hammer mill weight hammer mill van arsen ,Weight 165 lbs,Hammer Mills Chippers hammermill is used in the pelleting process to take raw chips which are many different sizes,The Van Aarsen pellet mill is well known in the market but remains a machine open to interestingFather forgives daughter for murdering their entire family ,27 Jun 2012,Arson The hammer mills aarsen× Contact Sales Call 3192328444 or 18003662563, or fill out the form belowHammermills CPM

Hammermill Hammers CPM

Pellet Mill Parts; Parts Hammermill Hammers Roskamp Champion is the industryleading hammermill supplier Our hammers are manufactured from highstrength carbon steel and finished with industryleading hardfacing technology for optimized grinding We offer quick turnaround times thanks to our large inventory Keep your hammermill operating efficiently by Professional in manufacturing and supplying mini pellet mill for small industrial and home pelletizing Compact structure, superior quality and competitive priceMini Pellet Mill for Home and Farm Use Wood Pellet MillAs the pellet mill can only process the raw materials with a diameter lower than 5mm, before the pelletizing process takes part in a pellet plant, the raw materials such as straw, bark, branches, corn stalk, need to be resized In that case, Hammer Mill Make Wood Pellets and Biomass Pellets

Hammer Mill for Biomass Pellet Plant

Hammer Mill The FSPZ hammer mill can pulverize such granule materials as corns, sorghum, various wheats, beans and rice dregs for biomass pellet plant, on top of that, it can also apply to sectors as chemical industry, foods and GEMCO biomass hammer mill has cooling function, temperature rise is lower when crushing the raw material What’s more, the crushed pellet is uniform Our wood hammer mill has the advantages of compact and reasonable structure, Hammer mill for wood chips biomass pelletHammer Mill for Feed, Biomass and Wood Pellet Plant Tear Drop Design, heavy duty hammer mill, Dynamically balanced Rotor, Wood Chips To Sawdust grinding for Wood, Biomass, Feed Pellet Production Plant, suitable for wet and dry wood, final output of 10mm to 80mm, 400hp motor, vibration sensor with heavy duty bearing pedestals, with easy opening doors for quick Hammer Mill for Feed, Biomass and Wood Pellet Plant Tear

High Efficiency Hammer Mill for Wood Pellets and Feed

Introduction to CF420A15 Diesel Hammer Mill This CF420A15 hammer mill is an ideal crushing machine for small scale pellets or briquettes production line, which can be used to grind the biomass materials (not more than 50mm) like straw, stalk and wood chip, tree branch and forest waste into powder of less than 35mm, which is right size before pelletizing and briquettePellet mill hammer mill weight hammer mill van arsen ,Weight 165 lbs,Hammer Mills Chippers hammermill is used in the pelleting process to take raw chips which are many different sizes,The Van Aarsen pellet mill is well known in the market but remains a machine open to interestingFather forgives daughter for murdering their entire family ,27 Jun 2012,Arson The hammer mills aarsenThe hammer mill is characterised by simple operation and handling The machine works according to the principle of crushing by multiple impact, so that the most effective crushing takes place by the direct impact of the hammer mill beater on the product The circumferential speed of the beater tip is approx 360 km/h Accordingly, screen perforations, beater designs, beater Hammer mill for the industry AMANDUS KAHL

Hammer Mill: Standard Operating Procedures

Hammer mill must not be operated solo At least two workers must be present when the mill is in use Operators must wear eye and hearing protection as well as nuisance at all times when operating the mill Operators must inform project leader when mill will be used 2 Before each use, check the coolant and oil level of the diesel motor Visually check that all bolts are The hammer mill is fixed with an engine with a power of RPdriven all kinds of different power Its working principle is: after the raw materials were put into crushing chamber, the highspeed operated hammer sheets will impact the raw materials over and over again, then the raw materials will be crushed into preset size stepbystep The sieve have the following size: Usermanual for hammer mill Zelf Pellets MakenChenfeng has brand effect about Feed production line including Biomass pellet mill, feed pelletizer machine, animal feed mill plant, hammer mill, feed granulator, feed mill equipment which can process feed for ruminant, livestock, poultry, cattle, chicken and broilerATS, Feed Mill, Pellet Mill, Pellet Machine, Extruder