cement production grinding unit to plant r

2022-03-27T15:03:07+00:00

Cement Grinding Plant Expert Cement Grinding Solutions

The main task of the cement grinding plant is to grind the cement clinker into particles with a certain fineness to make it into finished product cement Large cement plants usually include both clinker production lines and cement grinding lines, but there are also independent grinding plants that are only responsible for grinding and processing clinker into finished Cement rotary kiln Shaft kiln Cement grinding mill: our cement mill is widely applied to dry or wet cement grinding unit, it can be used as raw material mill, also apply for cement grinding plant Cement ball mill Vertical cement mill Cement roller pressCement Plant Cement Manufacturing Plant EPC Projectcement plant grinding unit manufacturer in Shanghai China cement plant grinding unit is manufactured from Shanghai It cement plant grinding unit is the project report for 1000 tpd capacity clinker grinding unit Get Price cement grinding unit in delhi jaypee cement s dalla clinker unit awaits green jaypee cement grinding unit to jaypee cement digisoft web Cement Production Grinding Unit To Plant greensplash

working of grinding unit of cement plant

Cement is produced by Grinding Clinker and Fly Ash with small quantity of Gypsum to regulate the setting time Our Cement Division currently Operates Modern, Computerized Process Control Cement Plants Jaypee Nigrie Cement Grinding Unit produces Special Blend of Portland Pozzolana Cement under the Brand Name 'Jaypee Cement' (PPC) Read MoreEmami Cement Limited Integrated Ultra Modern Cement ECLs integrated cement plant in Chhattisgarh with two split grinding units in West Bengal and Odisha has a total cement production capacity of around 8million tons per annum The stateoftheart integrated cement plant at Risda Baloda Bazaar is situated 70 km away from Raipur in Chhattisgarh A Cement Production Grinding Unit To Plant Machine Mining26/06/2019 The cement grinding plant includes: a feed module with material dosing and transport; a MVR 2500 C4 type vertical roller mill with a SLS 2650 BC ctype lassifier and drives; plant filter, fan and hot gas generator; electric switchgear with plant control system; silo plant; packing and palletising plants; and laboratory equipment The plant is designed to produce grinding plant Cement industry news from Global Cement

Cement Equipment For Finished Cement Plant Cement

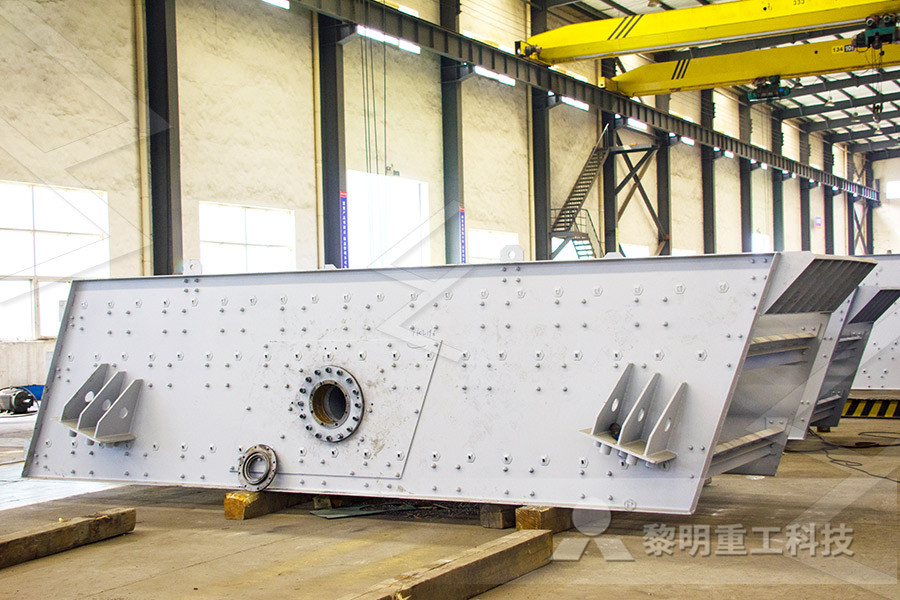

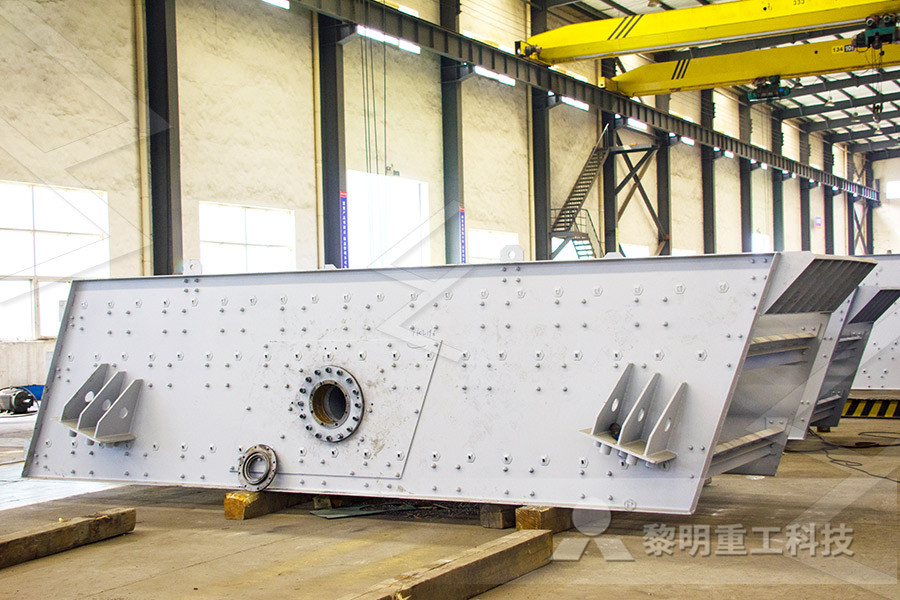

Cement grinding unit is a vital link in the cement production line and the most energyintensive process The main function of cement grinding plant is to grind cement clinker (and gelling agent, performance adjusting material, etc) into a suitable particle size (expressed by fineness, specific surface area, etc), form a certain particle gradation and increase its hydration areaHighly energy intensive unit operation of size reduction in cement industry is intended to provide a homogeneous and super fine (30004000 Blain) cement Grinding operation is monitored for following parameters to ensure objectivity and economy of operation Grinding Operation Objectives and KPIs Chemical analysis of cement, generally on hourly basis Product Cement Grinding Cement Plant Optimizationcement plant grinding unit manufacturer in Shanghai China cement plant grinding unit is manufactured from Shanghai It cement plant grinding unit is the project report for 1000 tpd capacity clinker grinding unit Get Price cement grinding unit in delhi jaypee cement s dalla clinker unit awaits green jaypee cement grinding unit to jaypee cement digisoft web Cement Production Grinding Unit To Plant greensplash

grinding plant Cement industry news from Global Cement

29/08/2018 Rwanda: Construction work has started on Prime Cement’s new grinding plant in Musanze District The subsidiary of Milbridge Group plans to complete the unit by mid2019, according to the New Times newspaper The plant is expected to have a cement production capacity of 07Mt/yr, with plans to expands this to 12Mt/yr Denmark’s signed a deal 12/12/2018 The unit will have a clinker production capacity of 3Mt/yr and a cement production capacity of 1Mt/yr The subsidiary of Switzerland’s LafargeHolcim plans to expand a 16Mt/yr grinding plant at Tikaria, Uttar Pradesh and a 22Mt/yr grinding plant also in Uttar Pradesh The board also agreed to build a 11Mt/yr grinding plant at an existing unit at Sindri grinding plant Cement industry news from Global CementCement plant is necessary for cement production, mainly consist of a series of cement equipment apply for preparation of cement raw materials, clinker production, and finished cement production, such as cement mill, cement crusher, rotary kiln, cement roller press, cement dryer, clinker cooler, cement silo, and related cement plant equipmentCement Plant, Cement Equipment Cement Plant Manufacturer

grinding plant Cement industry news from Global Cement

13/07/2018 Bangladesh: has confirmed that is to supply a cement grinding production line for Meghna Cement Mills The Danish equipment manufacturer has signed a contract with Meghna Cement Mills for engineering, procurement and supply of equipment for a 415t/hr Portland composite cement at 3800 Blaine grinding unit at it plant in Mongla in the 21/12/2016 India: My Home Industries plans to open a new cement grinding plant at Tuticorin, Tamil Nadu in January 2017 The new plant is expected to expand the company’s market share in southern India, according to the New Indian Express newspaper The cement producer has a production capacity of 84Mt/yr and the new unit will increase the total to 10Mt/yrgrinding plant Cement industry news from Global CementThe grinding unit at Bhabua in Bihar was acquired in 2018 from Eco Cements, with an initial cement production capacity of 06 MMTPA As of December 31, 2020, the Bhabua Cement Plant had an aggregate cement production capacity of 08 MMTPA We are undertaking a capacity expansion exercise at the Bhabua Cement Plant to increase its capacity to 2 Bhabua Cement Plant Cement Companies Double Bull Cement

Plants JK Cement Limited

The White Cement plant was commissioned in 1984 at Gotan, Rajasthan, with an initial production capacity of 50,000 tons JK Cement Works, Muddapur Situated near Muddapur village of Taluka Mudhol, district Bagalkot (Karnataka, the unit has the latest state of the art technology to manufacture 30 Million tonnes of cement per annumIn January 2021, the company announced its plan to invest US$ 137 million to increase production capacity of its integrated cement plant in Guwahati, Assam, by 2 MTPA The expansion plan is likely to complete by mid2023 In April 2021, ACC announced the expansion plan of its grinding unit in Tikaria with a 16 MTPA cement capacity Read More Cement working of grinding unit of cement plant19/07/2021 Shree Cement's 3Mta clinker grinding unit at Patas, Pune district in Maharashstra, India, is now expected to be completed soon with commercial production to commence in September, according to company official The western Indian expansion, which sits on a 266ha plot, had been delayed due to the impact of the COVID19 pandemic and rightofway Shree Cement to open 3Mta Pune grinding plant in September

Cement Manufacturing Process Phases Flow Chart

30/08/2012 Now cement plant grind the raw mix with the help of heavy wheel type rollers and rotating table Rotating table rotates continuously under the roller and brought the raw mix in contact with the roller Roller crushes the material to a fine powder and finishes the job Raw mix is stored in a prehomogenization pile after grinding raw mix to fine powder23/09/2021 Raysut Cement Co plans Duqm grinding plant start up for 4Q21 23 September 2021 Raysut Cement Co's (RCC) US$30m Duqm grinding unit in Oman will come onstream in the 4Q21 The Duqm plant will raise RCC’s group output to 74Mta, and help the company raise production to 10Mta by 2022 “Duqm plant will add another 1Mta to our capacity Raysut Cement Co plans Duqm grinding plant start up for 4Q21The grinding unit at Bhabua in Bihar was acquired in 2018 from Eco Cements, with an initial cement production capacity of 06 MMTPA As of December 31, 2020, the Bhabua Cement Plant had an aggregate cement production capacity of 08 MMTPA We are undertaking a capacity expansion exercise at the Bhabua Cement Plant to increase its capacity to 2 Bhabua Cement Plant Cement Companies Double Bull Cement

second hand grinding unit for cement plant

second hand grinding unit for cement plant,cement grinding unit in karnataka tata consulting engineers, state wsie list of cement plants 1, construction of bridge in karnataka cement grinding mill units buy vertical grinding machine for cement plant,ball mills produced in china are widely used in cement, coal, power plant we offer cement production line, stone Cement Manufacturing Process Flow Chart Cement manufacturing process is mainly divided into three stages, namely, raw meal preparation, clinker burning and cement grinding Generally speaking, the cement industry production is Portland cement Portland cement is a kind of delicate, usually gray powder, which consists of calcium (from limestone Cement Manufacturing Process Flow ChartThe grinding unit at Jajpur in Odisha was commissioned in 2018 while commercial production commenced in March 2020, with an initial cement production capacity of 2 MMTPA As of December 31, 2020, the Jajpur Cement Plant had an aggregate cement production capacity of 2 MMTPA The Jajpur Cement Plant is supplied with clinker from the manufacturing facilities Jajpur Cement Plant Cement Companies Double Bull Cement

Plants JK Cement Limited

The White Cement plant was commissioned in 1984 at Gotan, Rajasthan, with an initial production capacity of 50,000 tons JK Cement Works, Muddapur Situated near Muddapur village of Taluka Mudhol, district Bagalkot (Karnataka, the unit has the latest state of the art technology to manufacture 30 Million tonnes of cement per annumTherefore it is important that the manufacturer keeps his production unit as close as close as possible to the end customer Cement is basically is made by heating limestone (calcium carbonate) with small quantities of other materials to 1450°C in a kiln The resultant hard material which is recovered after heating limestone and chemicals is called ‘Clinker’ Clinker looks like Understanding How The Indian Cement Industry Works