nickel ore processing magnetic separation r

2023-02-20T00:02:13+00:00

Nickel Ore Processing Magnetic Separation

Upgrading low nickel content laterite ores using selective May 20, 2012 According to previous research, nickeliferous concentrates with nickel content of 51% and a nickel recovery of 988% could be produced from LN laterite ore by selective reduction and magnetic separation process when the reduction was conducted at 1250 C for 60 min (Li et al, 2010)Nickel Ore Processing Magnetic Separation Aquacristal 1/11/2020 The magnetic separation efficiency of nickel from the laterite ore was evaluated using the recovery ratio of nickel R ni using the formula (1) R Ni m Ni Ni M Ni Ni 100 % where m Ni is the mass of the magnetic product, g Ni is the nickel content inM Read More Separation And Recovery Of Iron And Nickel Ore Processing Magnetic SeparationNickel Ore Mineral Processing Nickel ore mainly consists of coppernickel sulfide ore and nickel oxide ore, beneficiation and processing of both methods is completely different Coppernickel sulfide ore beneficiation methods: The most important is theflotation The magnetic and the gravity separation is usually secondary dressing methodNickel Ore Processing Magnetic Separation Aquacristal

nickel ore processing magnetic separation

nickel ore processing magnetic separation Nickel ore processing plant The flotation is the main method among the copper sulfide nickel ore dressing methods Magnetic separation and gravity separation are Home Nickel Ore Processing Magnetic Separation Copper Ore Processing Equipment Capacity:0187 (m ³/min) Suitable Materials:Copper, zinc, lead, nickel, gold and other nonferrous metals, ferrous and nonmetal View Details Send Enquiry Ceramsite Production Line Production Capacity:705,000 t/d Raw Materials:Clay, mudstone, slate, gangue, coal ash, Nickel Ore Processing Magnetic SeparationNickel Ore Processing Magnetic Separation Aquacristal 1/11/2020 The magnetic separation efficiency of nickel from the laterite ore was evaluated using the recovery ratio of nickel R ni using the formula (1) R Ni m Ni Ni M Ni Ni 100 % where m Ni is the mass of the magnetic product, g Ni is the nickel content inM Read More Separation And Recovery Of Iron And Nickel Ore Processing Magnetic Separation

Nickel Ore Processing Magnetic Separation

Upgrading low nickel content laterite ores using selective May 20, 2012 According to previous research, nickeliferous concentrates with nickel content of 51% and a nickel recovery of 988% could be produced from LN laterite ore by selective reduction and magnetic separation process when the reduction was conducted at 1250 C for 60 min (Li et al, 2010)Nickel Ore Processing Magnetic Separation 8 rows Nickel Ore Mineral Processing Nickel ore mainly consists of copper nickel sulfide ore Professional Nickel Laterites Ores Magnetic Separation Price Magnetic separator for nickel in south africa aug 2 the is the professional mining equipments separation of nickel from nickel ore nickel cobalt cytec Nickel Ore Processing Magnetic SeparationSeparation and recovery of iron and nickel from lowgrade The current pyrometallurgical methods have been exploited for processing nickel metal from lowgrade laterite ore, such as in the metallic reduction roastingmagnetic separation process (KruppRenn Process),,,,,rotary kilnelectric furnace (RKEF) process,,,, and sinteringblast furnace nickel ore processing magnetic separation

magnetic separation nickel ore daikichisushifr

Nickel ore separation magnetic separator for nickel ore and spodumene ore US $1000$20000 / Set 10 Sets (Min Order) CN Shicheng County Jinchuan Mineral Equipment Manufacturing Co, Ltd 8 YRS 931% 41 (2) Contact Supplier 1/6 Neodymium magnet belt conveyor iron remover,metal separation process,separator type mineral magnetic separator 15/09/2020 Nickel ore is mainly divided into coppernickel sulfide ore and nickel oxide ore, and their beneficiation and processing methods are completely different The most important method for beneficiation of coppernickel sulfide ore is flotation, while magnetic separation and gravity separation are usually auxiliary beneficiation methods When Nickel beneficiation process,process design for 07/01/2020 Froth flotation process is the main mineral processing method used in the extraction of coppernickel sulfide ore, while the magnetic separation process and gravity separation process are usually used as the auxiliary mineral processing methods For the froth flotation process of coppernickel sulfide ore, the collector and foaming agents of copper How to Extract Nickel From CopperNickel Sulfide Ore?

Separation Nickel Magnetic brindedetentefr

Nickel Ore ProcessingOre Beneficiation Magnetic separation Nickel Ore Processing Nickel ore mainly consists of coppernickel sulfide ore and nickel oxide ore, beneficiation and processing of both methods is completely different nickel separation plant Treatment Tati Nickel Mining Company Tati Nickel mine is currently treating very low grade ore of less than 20/05/2012 Highlights Selective reduction and magnetic separation was conducted on low grade nickel laterite ore High grade nickeliferous concentrate could be produced from these laterite ores The addition of calcium sulphate promoted nickel concentration Nickel was mainly concentrated into a γ Fe–Ni phase in the reduced ore Calcium sulphate improved the growth Upgrading low nickel content laterite ores using selective magnetic separation Dry Magnetic Separation of Iron Ore: There are many inherent advantages in processes that utilize dry magnetic separation to beneficiate iron ore Wet concentration of magnetite ore, in comparison, re quires 500 to 1000 gal of water per ton of concen trate produced This means extensive use of waterADVANCES IN MAGNETIC SEPARATION OF ORES

Magnetic Separator For Nickel Ore alromfr

Magnetic Separator For Nickel Ore Alejandro FB05 Magnetic separator for nickel ore architektbergnerde Nickel Ore Magnetic Separation Nickel Ore Magnetic About 22 of these are mineral separator A wide variety of nickel ore magnetic separation options are available to you There are 29 nickel ore magnetic separation suppliers mainly located in Asia The top nickel ore processing magnetic separation Nickel ore processing plant The flotation is the main method among the copper sulfide nickel ore dressing methods Magnetic separation and gravity separation are nickel ore processing magnetic separationHome Nickel Ore Processing Magnetic Separation Copper Ore Processing Equipment Capacity:0187 (m ³/min) Suitable Materials:Copper, zinc, lead, nickel, gold and other nonferrous metals, ferrous and nonmetal View Details Send Enquiry Ceramsite Production Line Production Capacity:705,000 t/d Raw Materials:Clay, mudstone, slate, gangue, coal ash, Nickel Ore Processing Magnetic Separation

nickel ore processing magnetic separation

Separation and recovery of iron and nickel from lowgrade The current pyrometallurgical methods have been exploited for processing nickel metal from lowgrade laterite ore, such as in the metallic reduction roastingmagnetic separation process (KruppRenn Process),,,,,rotary kilnelectric furnace (RKEF) process,,,, and sinteringblast furnace Nickel ore separation magnetic separator for nickel ore and spodumene ore US $1000$20000 / Set 10 Sets (Min Order) CN Shicheng County Jinchuan Mineral Equipment Manufacturing Co, Ltd 8 YRS 931% 41 (2) Contact Supplier 1/6 Neodymium magnet belt conveyor iron remover,metal separation process,separator type mineral magnetic separator magnetic separation nickel ore daikichisushifrThe reduced ore was then upgraded by magnetic separation, 75 per cent of the total mass being rejected as tailings, and a high grade nickel concentrate, assaying 51 per cent Ni and 8266 per cent (PDF) Study on selective reduction and magnetic separation

Processing Nickel Ores Mine

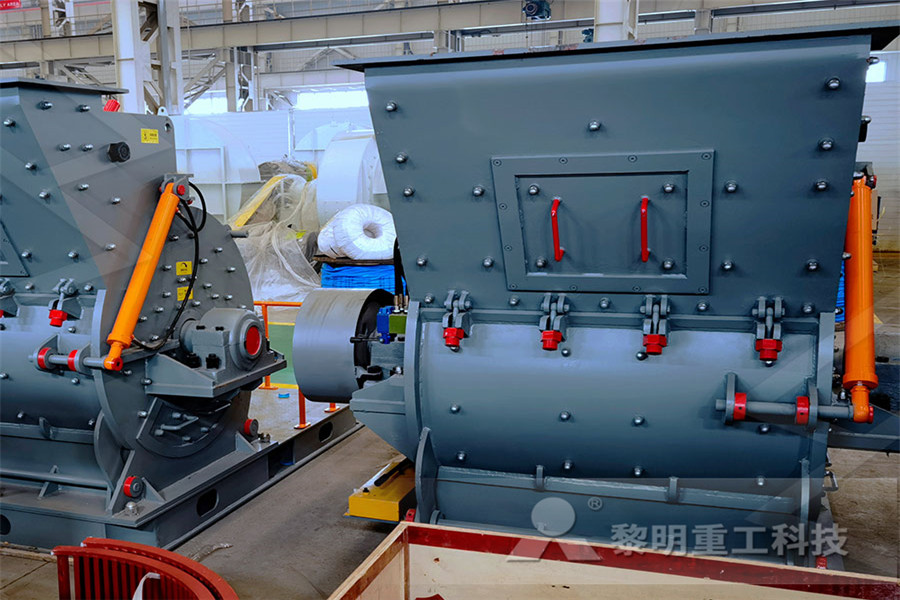

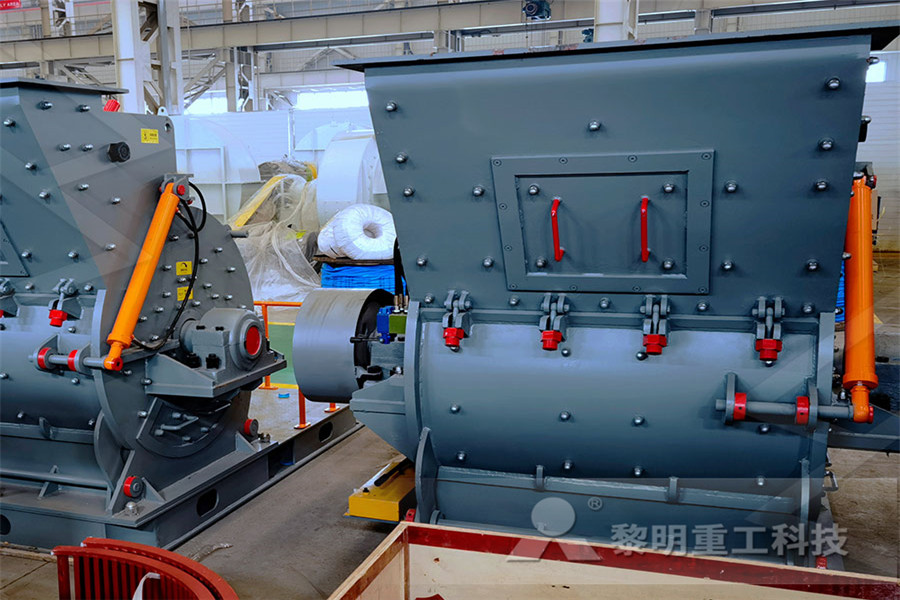

One Mine's Nickel Processing of Pyrrhoite, Chalcopyrite and Pentalandite Ores The ore is crushed to 5 inches in primary cone crushers, then reduced to 1/2" in short head cone crushers The ore is then ground to 100 mesh in ball mills Using wet magnetic separators the magnetic ore is separated (pyrrhotite) and further reduced to 200 mesh in a ball mill Classification is Keywords: nickel laterite ore, selective reduction roasting, magnetic separation Q LI et al XXV INTERNATIONAL MINERAL PROCESSING CONGRESS (IMPC) 2010 PROCEEDINGS / BRISBANE, QLD, AUSTRALIA / 6 STUDY ON SELECTIVE REDUCTION AND MAGNETIC SEPARATION Nickel Ore Processing Nickel ore divides into copper sulfide and copper oxide ore the main process for copper sulfide is flotation magnetic and gravity separation is the subsidiary process it is a high technological enterprise that integrated research manufacture sales and service the company has multiple subsidiaries such as mineral Nickel Ore Processing Magnetic Separation

Selective Reduction of Laterite Nickel Ore

Unlike sulphide nickel ore processing, laterite nickel ore processing requires higherprocessing energy through smeltingTherefore, a novel method to process laterite nickel ore using lower energy is needed The novel method is done via direct reduction and magnetic separation In laterite nickel processing by direct reduction, the challenges are to conduct selective