mill maintenance of fixed hammers r

2022-09-25T06:09:05+00:00

Hammermill Maintenance CPM

Hammermill Maintenance Basics There are three basic areas of hammermill maintenance: 1) Routine replacement items such as screen, hammers, and pins 2) Regular long term maintenance items such as flow directors, regrind chamber, and bearings 3) Long term maintenance items such as screen carriage, wear liners, and couplings Tip Speed Ranges27/10/2016 Replacing Hammer Mill Wear Parts Any machine that has moving or rotating parts requires routine maintenance to ensure that it performs at optimal capacity This is especially true of size reduction equipment which has grinding elements that will wear over time Inspecting and Replacing Wear Parts:Routine Hammer Mill Maintenance Schutte Hammermill31/05/2008 Access is an important part of any maintenance activity, particularly in the case of hammermills where screens and beaters need to be removed and refitted regularly Additionally, kibbling plates or disruptor bars fitted in the top quadrant of a hammermill or at the junction of screens need to be examined regularly and replaced periodically But it is often a case of Hammermill maintenance tips Worldgrain November

maintenance of hammer mill assurancesfamillepatrimoinefr

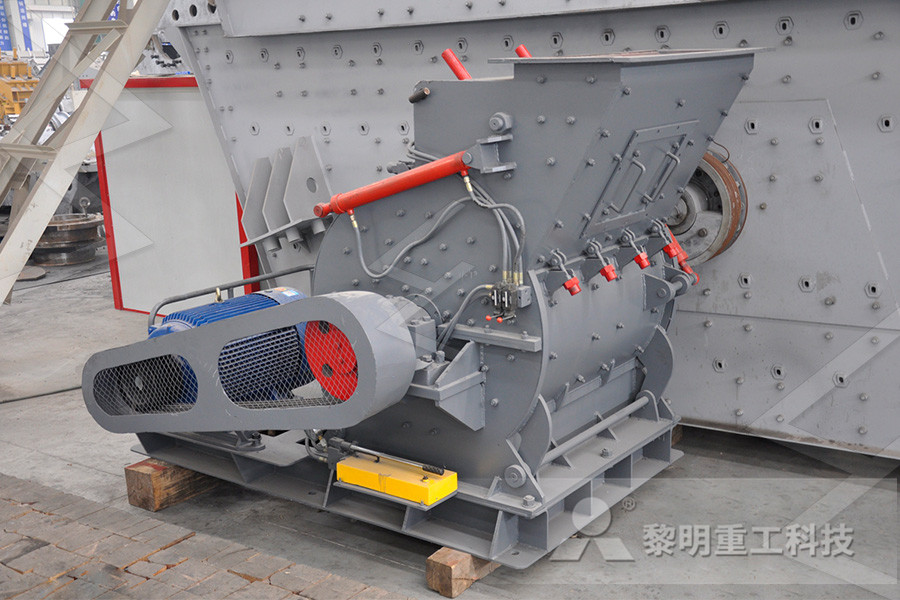

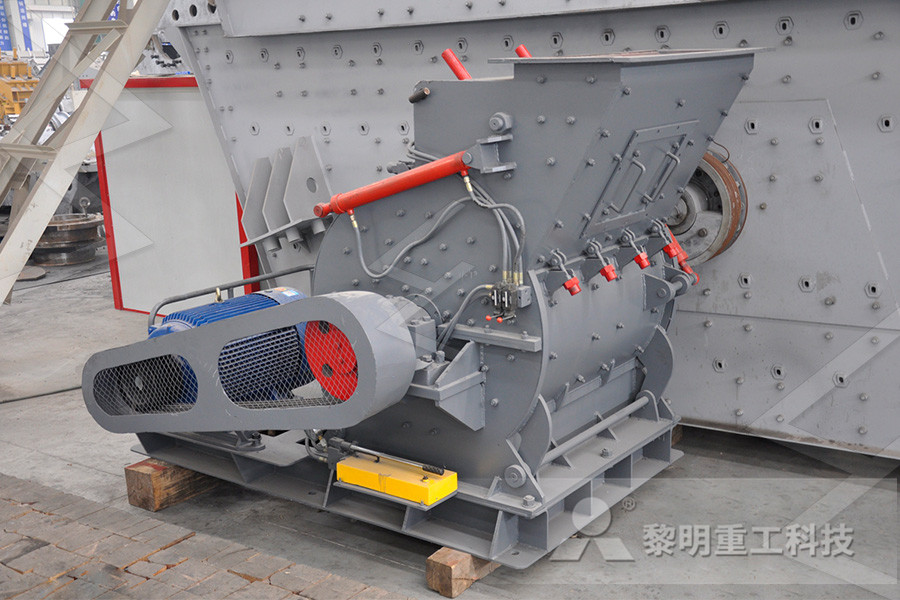

Maintenance Hammer Mill Rotor PANOLA Mining machine Maintenance Hammer Mill Rotor Yemmak hammer mill is constructed as a single unit consisting of a base frame with mill housing rotor for hammers side doors with screen frames and direct coupled electric motor with its robust structure and a construction that needs low maintenance these9” (230mm) diameter rotor with swinging or fixed mounted hammers and a mill top that hinges open for easy screen change, cleaning, and mill maintenance Optional fully integrated dust collection equipment ensures a clean, dust free environment America’s fastest growing hammermill compaThny QualityQUality, sincQe 1928QuaThe Industrial Hammer Mill: A Versatile Workhorse Crushing knives or hammers These are the fundamental tools that crush or grind materials They rotate at a high speed that may vary from 2,500 to 60,000 rpm A section of the hammer mill In most cases, these hammers are mounted on horizontal shafts where, they may rotate either clockwise or anticlockwise This may depend on the direction of the rotor rotation A The Working Principle of Hammer Mills (Stepbystep Guide)

maintenance of hammer mill ebenisteriestutzmannfr

maintenance steps you can take to keep your hammermill performing at peak levels while operating at lower cost , in your mill is called the hammer pattern Hammermill Maintenance CPM There are three basic areas of hammermill maintenance: 1) , as 38” diameter mills with RPM motors As hammer manufacturers improve theFull Article Optimizing Hammer Mill Performance Through Screen Selection And Hammer typically, the metal bars swing freely from the drum, but fixed hammers are also common in hammer mill designs hammer mills are recognized as technology capable of finely grinding the greatest variety of materials and are noted for achieving high size Learn More Chapter 18 Disadvantages Fixed Hammers In A Mill25/02/2016 The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone Thus far we have described machines which do a portion of their work by impact, but the only machine described in which this action plays an important role was the sledging roll type and particularly the Edison roll crusher Hammer Mill Crusher Grinder

Changing Hammers in a Pin Plate Style Hammermill

10/02/2011 Grinder Repair and Maintenance Changing Hammers in a Pin Plate Style Hammermill Posted by Powell Clinton ⋅ February 10, 2011 Filed Under fixed, hammer rod, Hammermill, horizontal grinder, plate, swing, Tub Grinder In this post we will describe how to change the hammers in your pin plate style hammermill for your tub grinder or horizontal fixed mounted hammers Mill top hinges open for easy screen change and mill maintenance Key Features: • Option of replaceable internal wear plates for processing abrasive materials • Choice of carbon or stainless steel construction • Wide selection of fourway reversible hammers • Numerous, easily changeable screens for the exact desired finished particle size Additional LAB SCALE HAMMER MILLAll Hippo mills have fixed hammers from hard wearing bennox steel rather than fails, allowing for greater particle damage Hammers are spaced to run over the entire width of the screen creating higher abrasion and impact damage to particles and allowing for faster screening The fallacy that 360 degree screens allow for higher capacity is just that The fixed milling backplate causes Hippo Hammer mills ABC Hansen Africa

Disadvantages Fixed Hammers In A Mill

Disadvantages Fixed Hammers In A Mill Roller mill roller mills used for the grinding of animal pet livestock poultry aquatic and other feed ingredients and grains roller mill hammer mill hammers beaters articles hammer mill hammers beaters disadvantages one roll is fixed in position and the other can be moved closer to or further from the fixed roll get priceThe Prater Mega Mill consists of a highspeed rotor with hammers fixed to support pins at their pivot point and equally spaced around the grinding chamber in a specific pattern The rotor is supported by precision bearings, allowing the hammers to operate with very close tolerance to one or more screens fixed within the frame Size reduction is created by the repeated impact Mega Mill Hammer Mill Industrial Hammer MillHammer Mill Fixed Hammer And Free Hammers Hammer Mill Fixed Hammer And Free Hammers Hammer Article about hammer by The Free Dictionary hammer 1 a hand tool consisting of a heavy usually steel head held transversely on the end of a handle, used for driving in nails, beating metal, etc 2 any tool or device Get PriceHammer Mill Fixed Hammer And Free Hammers

CHAPTER 20: SIZE REDUCTION – EQUIPMENT FOR SIZE REDUCTION

MAINTENANCE Unit operation in which the average size of solid pieces of food is reduced by the application of • One plate is stationary and fixed with the body of the mill while the other one is rotating disk • Material is fed between the plates and is reduced by crushing and shear • Mills with different patterns of grooves, corrugations on the plates perform a variety of Crushing knives or hammers These are the fundamental tools that crush or grind materials They rotate at a high speed that may vary from 2,500 to 60,000 rpm A section of the hammer mill In most cases, these hammers are The Working Principle of Hammer Mills (Stepbystep Disadvantages Of Hammer Mill Disadvantages fixed hammers in a mill advantages disadvantages of cement industry this report will demonstrate that while the hammer mill and dual rotor shredder yielded both advantages and disadvantages the hammer mill is clearly the more robust and versatile machine for long term use proposal b is a full As a leading global disadvantages fixed hammer in a mill

Hippo Hammer mills ABC Hansen Africa

All Hippo mills have fixed hammers from hard wearing bennox steel rather than fails, allowing for greater particle damage Hammers are spaced to run over the entire width of the screen creating higher abrasion and impact damage to particles and allowing for faster screening The fallacy that 360 degree screens allow for higher capacity is just that The fixed milling backplate causes Disadvantages Fixed Hammers In A Mill Roller mill roller mills used for the grinding of animal pet livestock poultry aquatic and other feed ingredients and grains roller mill hammer mill hammers beaters articles hammer mill hammers beaters disadvantages one roll is fixed in position and the other can be moved closer to or further from the fixed roll get priceDisadvantages Fixed Hammers In A MillThe hammer can be fixed or mentioned that a hammer mill with 16 hammers, a 458 mm screen, and an operating speed of 3600 rpm was effective at grinding a mixture of 124 mm (minorHammer Crusher Our hammer crusher includes small hammer crusher and heavy hammer crusher The hammer crusher also named hammer mill, it crushes by the collisions Hammer Mill Fixed Hammer And Free Hammers

material of hammermill hammers johtamaeschool

Hammermill maintenance for top grinding performance at a rather than fixed, hammers, but most of the advice here can be applied to other hammermill types A hammermill is one of the toughest finegrinding machines at work in today's bulk solids plants The mill handles a wide variety of friable and fibrous materials, including grains, oil seeds, wood scraps, Get Price → 24/08/2010 These fixed hammer machines are generally the “big boys” or the “work horses” of the industry and are generally from 350 horse power to 1500 horse power in size Now most of the newer tub grinders are equipped with a tilt tub to make changing these hammers much easier than what the older models used to require The first priority is to get the machines cutting Hammer Replacement on TubGrinders urcrecycleDisadvantages fixed hammers in a mill bgdirectory advantages and disadvantages of using hammer mill construction advantages and disadvantages of hammer mill Hammer Mill, Rotor of a Hammer Mill, Hammer Pins, Catch Device 15 Nov 2012 [0004] The más Read More++ fixed head rotary hammer mill Hammer Mill: components, operating principles, Hammer mill is mill fixed hammer pistazienfuchsch

HammerMill Cellulosemill

Fiberization of any kind of treated or untreated cellulose pulp (1 or 2 sheets infeed) Rotor width 10" or 20" or 25" Rotor diameter 508mm or 800mm09/04/2015 12 Hammer mill • It is most widely used equipment for food size reduction by impact forces • It is used to produce wide range of particles like from medium to fine • Hammers or beaters are provided for size reduction, so it called as hammer mill • It is based on impact and shear force 13Milling and milling equipments SlideShare