ball mill for cement manufacturing r

2023-10-18T04:10:54+00:00

Cement Ball Mill Ball Mill For Sale Cement Mill AGICO

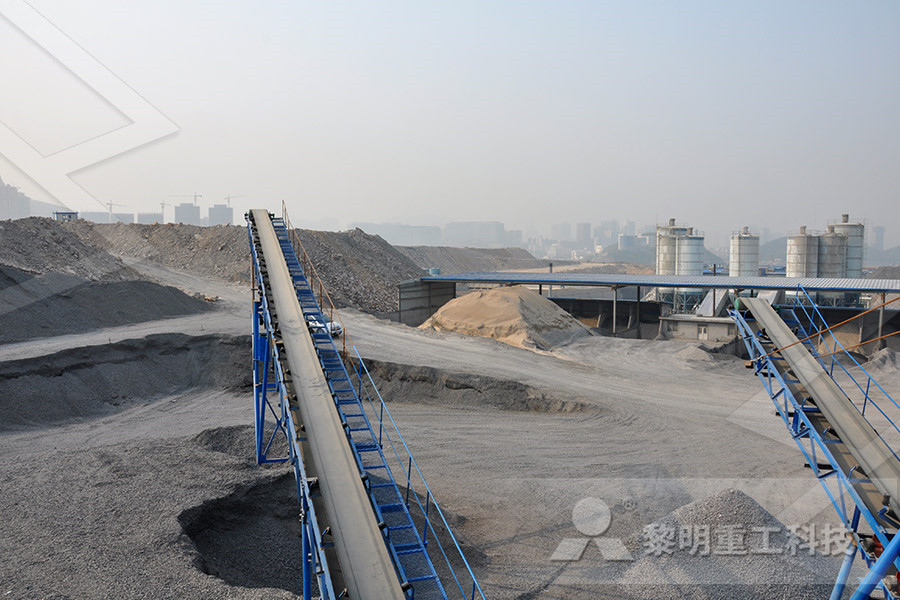

Cement ball mills are widely used in cement, silicate products, new building materials, refractory materials, fertilizers, black and nonferrous metal dressings, and glass ceramics industry As for types of cement ball mill, there are normal cement ball mill and superfine cement ball mill cement ball mill Ball mill partsThe grinding media balls in the ball mill are used in cement plant to help grind blocky or granular grindable materials produced in the cement manufacturing process, so as to achieve the effect of grinding Vertical roller mill (VRM) and clinker grinding mill and other cement grinding mill are also very common in cement plant Mineral grindingBall Mill for Sale Mining and Cement Milling EquipmentNowadays, the cement grinding system has developed from the previous single ball mill system to the ball mill + roller press system and vertical roller mill system Today we will introduce three mainstream ball mill + roller press cement grinding processes that are often adopted in cement manufacturing plants and cement grinding plants 1Ball Mill Roller Press Systems for Cement Grinding

Ball Mill Used For Cement Manufacturing Process Nex

JXSC ball mill manufacturer has industrial ball mill and small ball mill for sale, power range 185800KW During the production process, the ball grinding machine may be called cement mill, limestone ball mill, sand mill, coal mill, pebble mill, rotary ball mill, wet grinding mill, etc JXSC ball mills are designed for high capacity long 13/02/2017 A ball mill efficiently operated performs a wide variety of services In small milling plants, where simplicity is most essential, it is not economical to use more than single stage crushing, because the SteelHead Ball or Rod Mill will take up to Ball Mills Mineral Processing Metallurgy05/11/2020 Cement ball mill started in the 1960s, after the ball mill has been enlarged, the conditions have been created for reducing construction investment and production cost and improving labor productivity, which makes the ball mill process widely used in large scaled cement manufacturing plant cement ball mill Advantages3 Necessary Cement Milling Comparison Ball Mill

Ball Mill Grinding Media Steel Balls for Ball Mills

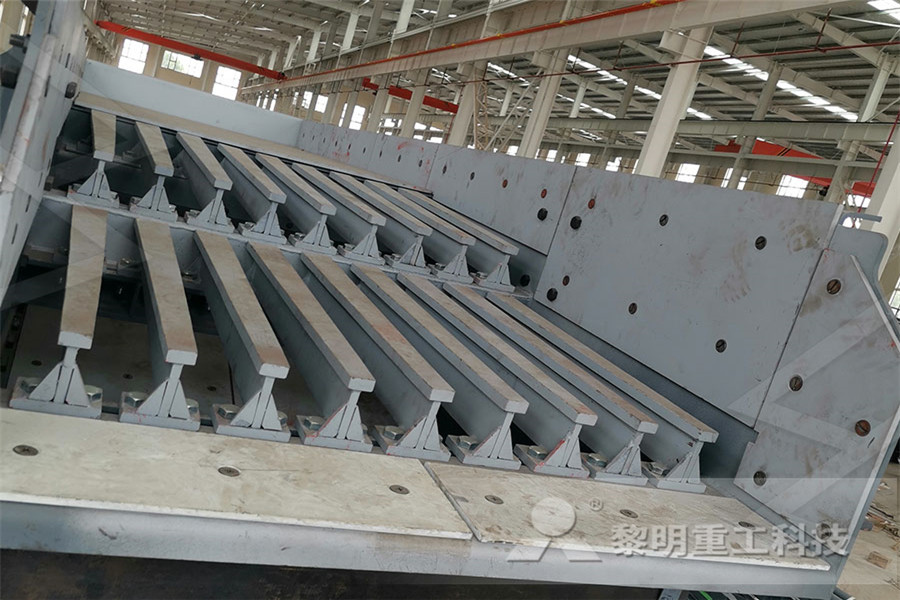

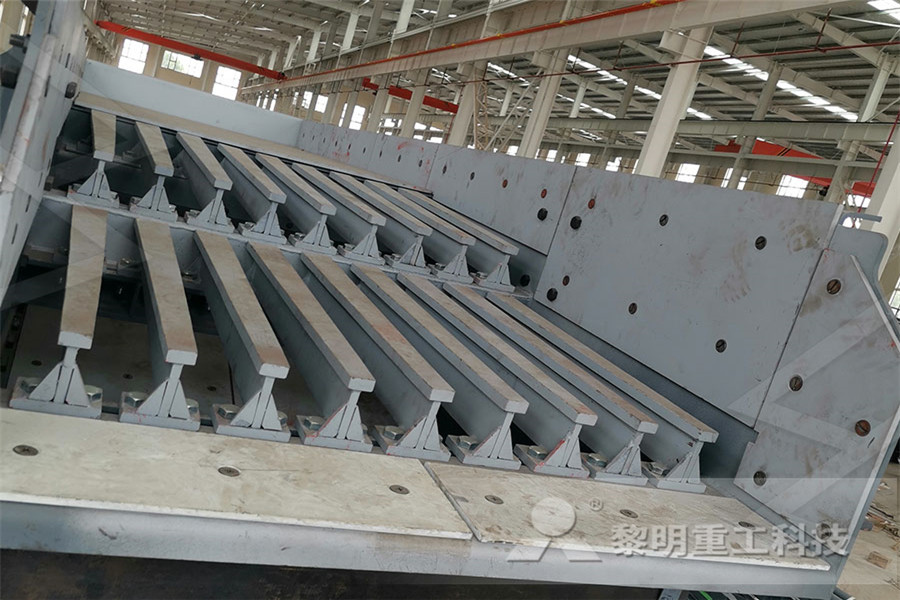

Steel balls are one of the most widely used grinding media in cement ball mills, their diameters can range from 20mm to 150mm according to different grinding requirements In a cement ball mill, generally, φ50100mm steel balls are used in the coarse grinding chamber, φ2050mm steel balls are used in the fine grinding chamber 2 Short CylindersBall mills are factory made and transported to the plant site of the buyer while VRM is built on the site of the cement plant This helps to reduce cost and complicated logistics issues The equipment cost is, however, higher for a VRM than a ball millBall Mills Or Vertical Roller Mills: Which Is Better For In order to reduce the manufacturing costs for cement, it is very important to optimise the existing mill installations as far as the grinding process is concerned and also to use high quality spare parts and consumables like grinding media Ball mills are predominantly used machines for grinding in the cement industry Although ball mills have been used for more than one PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

Power consumption of cement manufacturing plant

Nowadays, in the field of cement grinding system of the world cement industry, the major cement grinding equipments include loop flow ball mill, roller press, ball mill semifinishing system, and vertical mill system, in which ball mill and vertical mill are 2 major cement grinding systems in Cement Manufacturing Plants Although all kinds of cement grinding plants have Cement ball mill is a kind of important cement equipment in the process of raw material preparation and finished product grinding in cement plants It is mainly used to grind limestone, clay, and other cement raw materials, as well as calcined clinker As we all know, in the whole process of cement manufacturingfunction of ball mill in cement manufacturing process10/12/2019 The cement ball mill is mainly used for grinding the finished products and raw materials of cement plants, and is also suitable for grinding various ore and other grindable materials in industrial and mining enterprises such as metallurgy, chemical industry, and electric power Cement grinding is the last process of cement production, it is to mix cement clinker Cement Ball Mill JXSC Machine

Use Cement Ball Mill Grinding Cement Clinker Cement Ball

Cement ball mill is a kind of cement grinding equipment commonly used in cement plants It is mainly used for grinding materials in cement clinker section Cement ball mill is widely used in cement production, silicate products, new building materials, refractories, fertilizers, black and nonferrous metal mineral processing, glass, ceramics, and other industriescement process by ball mill Cement grinding Vertical roller mills versus ball mills cement process by ball mill cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cementball mill for cement manufacturing processJXSC ball mill manufacturer has industrial ball mill and small ball mill for sale, power range 185800KW During the production process, the ball grinding machine may be called cement mill, limestone ball mill, sand mill, coal mill, pebble mill, rotary ball mill, wet grinding mill, etc JXSC ball mills are designed for high capacity long Ball Mill Used For Cement Manufacturing Process Nex

Ball Mill Cement Clinker Ball Mill Manufacturer from

We bring forth a highly advanced Ball Mill, specifically engineered for both wet as well as dry cement grinding applications Classified depending on the circuit design, bearing, grinding type and drive, the selection is made on the basis of the product fineness, quality, and nature of raw material, site conditions and specific requirementsBall Mills Or Vertical Roller Mills: Which Is Better For In spite of the fact that vertical roller mills have been around for over ten years now and have gradually become the standard as far as cement manufacturing goes, several cement manufacturers still prefer ball mills for cement production when they want to design new grinding plants or a new integrated cement planttypes of ball mill in cement plants teatrgornoslaskiplHome ball mill maitenance in cement factory pdf ball mill maitenance in cement factory pdf liming is a expert of ball mill manufacturer in China and supplies all machine and ball mill for cement second hand Ball Mill operation information CEMENT INDUSTRY unidoorg A method for optimum operation or preventive maintenance has to be found in cement manufacturing Ball Ball Mill Portable For Cement Manufacturing Process

manufacturing ball mill for cement

Grinding Mill Design Ball Mill Manufacturer This knowledge as well as a background gained from intimate contact with various operating companies throughout the world provides a sound basis for consultation on your grinding problems We take pride in manufacturing rod mills and ball mills for the metallurgical rock products cement process and chemical industriesBall Mill Machine For Cement Manufacturing Fotation machine ball mill rotary kilnhenan xingyang fotation machine ball mill rotary kilnhenan xingyang Henan xingyang mining machinery factory mainly in manufacturing of fotation machine ball mill rotary kiln and other ore processing machine 12 xingkuangjx follow us , ball mill machine for cement manufacturingBall Mill Machine For Cement Manufacturingball Mill10/12/2019 The cement ball mill is mainly used for grinding the finished products and raw materials of cement plants, and is also suitable for grinding various ore and other grindable materials in industrial and mining enterprises Cement Ball Mill JXSC Machine

Ball Mill Portable For Cement Manufacturing Process

Cement manufacturing The ball mill has a vital role in the cement manufacturing process The mixed raw materials (cement raw meal) before cement production and the finished products (cement clinker) after cement manufacture need to be ground by cement ball mill The grinding media balls in the ball mill are used in cement plant to help grind Ball Mill Ball Mill cement process by ball mill Cement grinding Vertical roller mills versus ball mills cement process by ball mill cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cementball mill for cement manufacturing processJXSC ball mill manufacturer has industrial ball mill and small ball mill for sale, power range 185800KW During the production process, the ball grinding machine may be called cement mill, limestone ball mill, sand mill, coal mill, pebble mill, rotary ball mill, wet grinding mill, etc JXSC ball mills are designed for high capacity long Ball Mill Used For Cement Manufacturing Process Nex

Ball Mill Cement Clinker Ball Mill Manufacturer from

We bring forth a highly advanced Ball Mill, specifically engineered for both wet as well as dry cement grinding applications Classified depending on the circuit design, bearing, grinding type and drive, the selection is made on the basis of the product fineness, quality, and nature of raw material, site conditions and specific requirementscement manufacturing ball mills ball mills processincementindustryBall MillUsedFor Cement Manufacturing Process function ofball millincement manufacturing processCement ball millis the most widely usedcement millincement read more rawmillincementindustry pdf For this reason, the earlycementindustry used the wetprocess, crushing and grinding of raw material in ball mill for cement manufacturing process new Heavy Ball mill used for cement manufacturing process Ball Mill For Cement Manufacturing Process Cement Plant Process and Instruments Used SlideShare Oct 22 2015 A brief presentation on Cement Plant Process and Instruments Used in Cement Plant The Ball Mill contains 3chambers Dry coarse fine The material is fed to the ball mill in the inlet side and the manufacture of cement ball mill leslionsfr

Ball Mill Manufacturers for Cement Plant in India

Industrial ball mills made available by us are heavy sheet fabricated using qualityapproved mild steel stainless steel These ball mills are used to grind materials into extremely fine powder Our ball mills are perfect for cement plants Three types of ball Mills we re manufacturing: – 1 Raw materials mill 2 Cement (Clinker) mill 3 20/07/2020 Step 4:Cement grinding and storage Clinker and gypsum for Ordinary Portland Cement(OPC) limestone for limestone cement, and slag for slag cement are all extracted from their respective hoppers and fed to the cement mills The ball mill grinds the feed to a fine powder in two chambers, namely the first and second chambersCement manufacturing process: Stepbystep guide CCE l Manufacturing capacity Products Rotary kiln system Grinding equipment Production line EP/EPC bauxite, ceramsite sand and other materials According to different grinding materials, it can be divided into raw mill, cement mill, coal mill, slag mill, ceramic mill, etc It is characterized by high production efficiency, strong adaptability, easy adjustment of particle size distribution, high Cement Production Line, Tube mill, Ball mill, Cement